- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XK-SN

-

Shape:

-

Powder, Granules, Ingot, Pellet

-

Material:

-

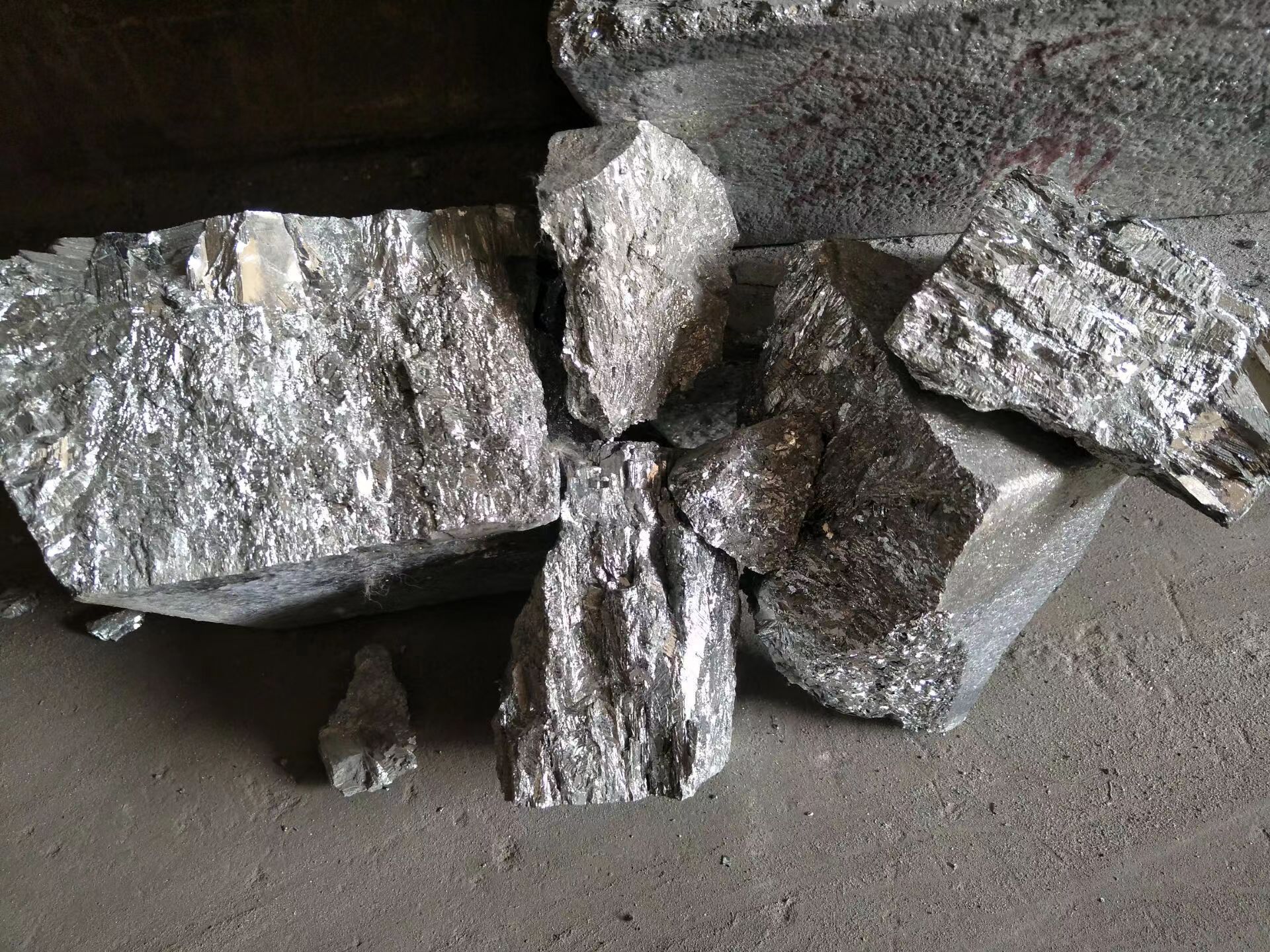

Antimony Ingot

-

Chemical Composition:

-

Sn, Sn

-

Product name:

-

Antimony Ingot

-

Purity:

-

Standard

-

Usage:

-

Widely

-

Color:

-

Silver Gray

-

Appearance:

-

Cleaning

-

Package:

-

Bag

-

Advantage:

-

Ship Timely

-

Characteristic:

-

Low Defect Rate

-

MOQ:

-

20 Mt

-

Delivery time:

-

15-20 Days

Quick Details

-

Application:

-

Industry

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Chengmai

-

Model Number:

-

XK-SN

-

Shape:

-

Powder, Granules, Ingot, Pellet

-

Material:

-

Antimony Ingot

-

Chemical Composition:

-

Sn, Sn

-

Product name:

-

Antimony Ingot

-

Purity:

-

Standard

-

Usage:

-

Widely

-

Color:

-

Silver Gray

-

Appearance:

-

Cleaning

-

Package:

-

Bag

-

Advantage:

-

Ship Timely

-

Characteristic:

-

Low Defect Rate

-

MOQ:

-

20 Mt

-

Delivery time:

-

15-20 Days

Product Description

Manganese-silicon alloy is a kind of alloy composed of manganese, silicon, iron and small amount of carbon and other elements.

It’s a widely-used and productive ferroalloy. It’s consumption is ranked the second in electric furnace ferroalloy products.

The manganese and silicon in it has strong affinity for oxygen, using manganese-silicon alloy in steelmaking would produce the deoxy products MnSiO3 and Mn2SiO4 (the melting point are 1270℃ and 1327℃ respectively)which have the advantages of low melting point, large particle , easy to float and good deoxidation effect, etc. Under the same conditions, using manganese or silicon to

deoxidize alone, the damage rates are 46% and 37% ,while the damage rate is 29% when using manganese-silicon alloy. Therefore, it is widely used in steelmaking, the growth rate of it’s output is higher than the average growth rate of ferroalloy’s and even higher than that of the steel’s, has become the indispensable compound deoxidizer and alloy additive in steel industry. For manganese silicon alloy which carbon content is less than 1.9% can be used as semi-products in producing medium and low carbon ferromanganese and electro silicothermic manganese metal.

It’s a widely-used and productive ferroalloy. It’s consumption is ranked the second in electric furnace ferroalloy products.

The manganese and silicon in it has strong affinity for oxygen, using manganese-silicon alloy in steelmaking would produce the deoxy products MnSiO3 and Mn2SiO4 (the melting point are 1270℃ and 1327℃ respectively)which have the advantages of low melting point, large particle , easy to float and good deoxidation effect, etc. Under the same conditions, using manganese or silicon to

deoxidize alone, the damage rates are 46% and 37% ,while the damage rate is 29% when using manganese-silicon alloy. Therefore, it is widely used in steelmaking, the growth rate of it’s output is higher than the average growth rate of ferroalloy’s and even higher than that of the steel’s, has become the indispensable compound deoxidizer and alloy additive in steel industry. For manganese silicon alloy which carbon content is less than 1.9% can be used as semi-products in producing medium and low carbon ferromanganese and electro silicothermic manganese metal.

Specification

|

Grade

|

Mn min

|

Si min

|

P max

|

S max

|

C max

|

|||||

|

Mn65Si17

|

65

|

17

|

0.25

|

0.04

|

2.5

|

|||||

|

Mn60Si14

|

60

|

14

|

0.3

|

0.05

|

2.5

|

|||||

|

As per your requirement

|

|

|

|

|

|

|||||

|

|

Chemical Composition/%

|

|

|

|

|

|

|

|

|||||||

|

|

Si

|

Al

|

Ca

|

Mn

|

Cr

|

P

|

S

|

C

|

|||||||

|

|

|

≤

|

|

|

|

|

|

|

|||||||

|

FeSi75A10.5-A

|

74.0-80.0

|

0.5

|

1.0

|

0.4

|

0.3

|

0.035

|

0.02

|

0.1

|

|||||||

|

FeSi75A10.5-B

|

72.0-80.0

|

0.5

|

1.0

|

0.5

|

0.5

|

0.04

|

0.02

|

0.2

|

|||||||

|

FeSi75A11.0-A

|

74.0-80.0

|

1.0

|

1.0

|

0.4

|

0.3

|

0.035

|

0.02

|

0.1

|

|||||||

|

FeSi75A11.0-B

|

72.0-80.0

|

1.0

|

1.0

|

0.5

|

0.5

|

0.04

|

0.02

|

0.2

|

|||||||

|

FeSi75A11.5-A

|

74.0-80.0

|

1.5

|

1.0

|

0.4

|

0.3

|

0.035

|

0.02

|

0.1

|

|||||||

|

FeSi75A11.5-B

|

72.0-80.0

|

1.5

|

1.0

|

0.5

|

0.5

|

0.04

|

0.02

|

0.2

|

|||||||

|

FeSi75A12.0-A

|

74.0-80.0

|

2.0

|

1.0

|

0.4

|

0.3

|

0.035

|

0.02

|

0.1

|

|||||||

|

FeSi75A12.0-B

|

74.0-80.0

|

2.0

|

1.0

|

0.4

|

0.3

|

0.04

|

0.02

|

0.1

|

|||||||

|

FeSi75A12.0-C

|

72.0-80.0

|

2.0

|

|

0.5

|

0.5

|

0.04

|

0.02

|

0.2

|

|||||||

|

FeSi75-A

|

74.0-80.0

|

|

|

0.4

|

0.3

|

0.035

|

0.02

|

0.1

|

|||||||

|

FeSi75-B

|

74.0-80.0

|

|

|

0.4

|

0.3

|

0.04

|

0.02

|

0.1

|

|||||||

|

FeSi75-C

|

72.0-80.0

|

|

|

0.5

|

0.5

|

0.04

|

0.02

|

0.2

|

|||||||

|

FeSi65

|

65.0-<72.0

|

|

|

0.6

|

0.5

|

0.04

|

0.02

|

|

|||||||

|

FeSi45

|

40.0-47.0

|

|

|

0.7

|

0.5

|

0.0

|

|

|

|||||||

Packing & Delivery

Hot Searches