Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

KL-16

Quick Details

-

CAS No.:

-

N/M

-

Place of Origin:

-

China

-

Brand Name:

-

Kanglibang

-

Model Number:

-

KL-16

Products Description

KANGLIBANG®

UV Glue

The UV glue is a single-component, high solid content, ultraviolet-cured modified polyurethane acrylate that can be coated on film materials. The film is cured with anaerobic ultraviolet light, features high adhesiveness and moisture resistance, high transparency, and is safe and non-toxic. It does not contain any solvents, and has no VOC.

|

|

KL-UV-001

|

KL-UV-002

|

KL-UV-003

|

|

Appearance

|

Colorless transparent viscous liquid

|

Colorless transparent viscous liquid

|

Colorless transparent viscous liquid

|

|

Viscosity(25℃)

|

3000±500 CPS

|

8000±1000 CPS

|

200-500 CPS

|

|

Storage temperature

|

Store away from light at 0-35℃

|

Store away from light at 0-35℃

|

Store away from light at 0-35℃

|

|

Shelf life

|

6 Months

|

6 Months

|

6 Months

|

Advantages:

1. Fast Curing Time:

UV glue cures rapidly when exposed to UV light, often within seconds. This quick curing time significantly reduces waiting periods, increases production speeds, and allows for faster repairs and processing.

2. Strong Bond: Once cured, UV adhesive forms a strong and durable bond between surfaces. It is capable of bonding various materials, including glass, metal, plastic, and wood, providing a versatile solution for different industries.

3. Clear Finish: UV glues typically cure to a clear finish, which is ideal for applications where aesthetics matter. The

transparent bond is especially beneficial in glass bonding and other transparent materials, preserving the visual appeal of the items being adhered.

4. Solvent-Free: Most UV adhesives are solvent-free, which means they don't release harmful solvents or VOCs (volatile organic compounds) during curing. This makes UV glue a safer and more environmentally friendly option compared to some traditional adhesives.

5. Precise Application: UV glue can be applied with precision to specific areas without spreading or dripping, ensuring clean and accurate bonding. This is particularly useful in detailed work or in applications where excess adhesive needs to be avoided.

6. Temperature and Chemical Resistance: Many UV glues offer excellent resistance to temperature fluctuations, chemicals, and moisture, making them suitable for use in harsh environments.

7. No Need for Heat: UV-curing adhesives do not require heat to cure, making them suitable for bonding heat-sensitive materials without risk of damage.

8. Energy Efficient: The curing process for UV glue is energy efficient, as it only requires light exposure to cure. This can lead to lower energy consumption compared to adhesives that require heat or longer curing times.

2. Strong Bond: Once cured, UV adhesive forms a strong and durable bond between surfaces. It is capable of bonding various materials, including glass, metal, plastic, and wood, providing a versatile solution for different industries.

3. Clear Finish: UV glues typically cure to a clear finish, which is ideal for applications where aesthetics matter. The

transparent bond is especially beneficial in glass bonding and other transparent materials, preserving the visual appeal of the items being adhered.

4. Solvent-Free: Most UV adhesives are solvent-free, which means they don't release harmful solvents or VOCs (volatile organic compounds) during curing. This makes UV glue a safer and more environmentally friendly option compared to some traditional adhesives.

5. Precise Application: UV glue can be applied with precision to specific areas without spreading or dripping, ensuring clean and accurate bonding. This is particularly useful in detailed work or in applications where excess adhesive needs to be avoided.

6. Temperature and Chemical Resistance: Many UV glues offer excellent resistance to temperature fluctuations, chemicals, and moisture, making them suitable for use in harsh environments.

7. No Need for Heat: UV-curing adhesives do not require heat to cure, making them suitable for bonding heat-sensitive materials without risk of damage.

8. Energy Efficient: The curing process for UV glue is energy efficient, as it only requires light exposure to cure. This can lead to lower energy consumption compared to adhesives that require heat or longer curing times.

Product Paramenters

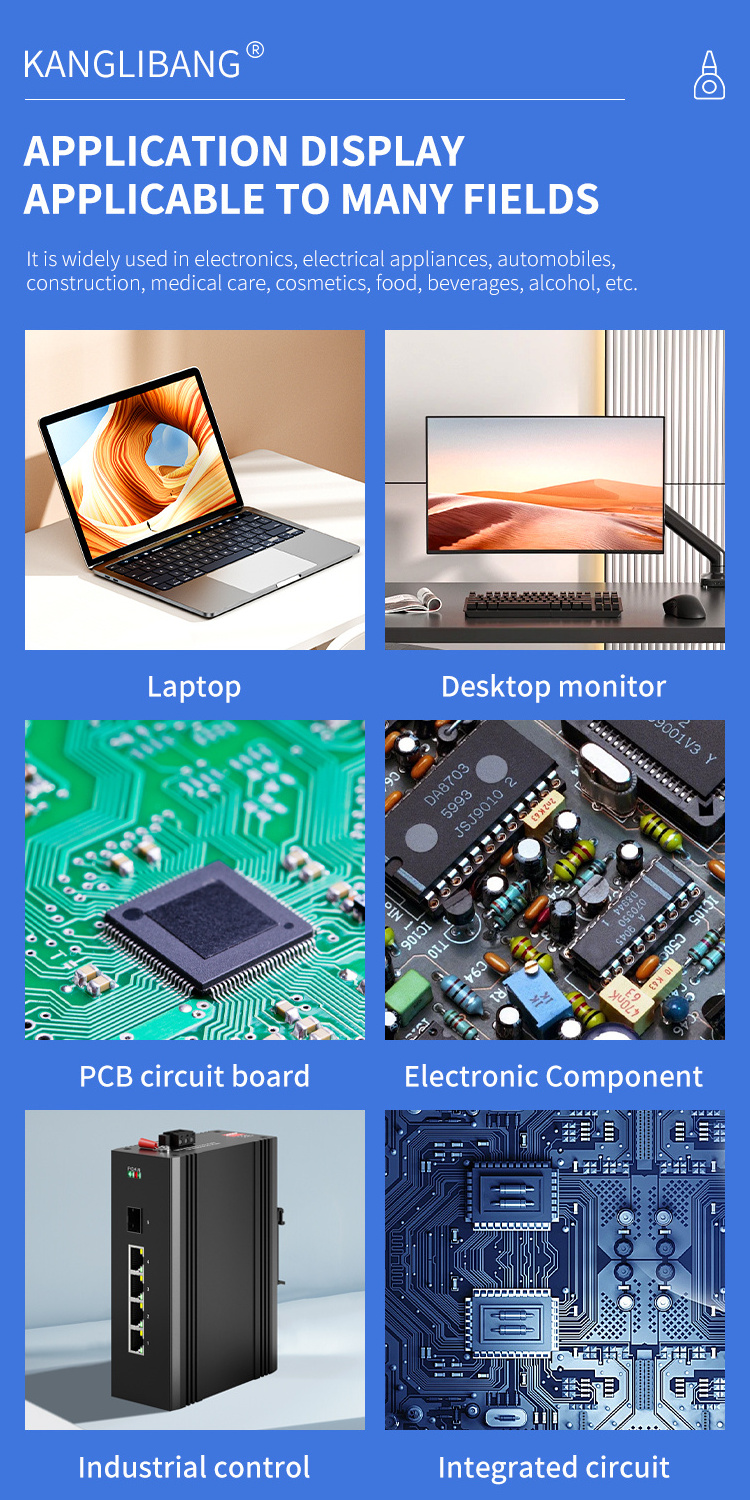

Application for

UV Glue

1. Glass Bonding:

One of the primary uses of UV glue is in the glass industry. It's extensively used for bonding glass to glass and glass to metal, making it ideal for assembling decorative glassware, glass furniture, and architectural elements like glass facades.

2. Consumer Electronics: UV glue is employed in the assembly of various consumer electronics, including smartphones, tablets, and televisions. It is used for bonding screens, lenses, and other components due to its clear finish and strong bond.

3. Medical Devices: In the medical industry, UV glue is utilized for assembling disposable and reusable medical devices. Its biocompatibility, strong adhesion, and fast curing time make it suitable for producing syringes, catheters, tube sets, and other medical equipment.

4. Automotive: UV-curing adhesives are used in the automotive industry for bonding sensors, headlamps, and plastic components. Their resistance to temperature and moisture makes them particularly useful in vehicles.

5. Optical and Photonics: UV glue is critical in the production of optical devices, including lenses, prisms, and fiber optic components. It ensures precise alignment and bonding without affecting the optical properties of components.

6. Jewelry Making: In the field of jewelry making, UV glue is used to bond gems and other decorative elements to metal substrates. Its clear finish and strong bond make it ideal for this application.

7. Packaging: For packaging applications, especially in the cosmetics industry, UV glue is used to assemble plastic packaging, secure labels, and bond decorative elements. Its rapid curing time improves production efficiency.

8. Dental Applications: UV-curing adhesives are used in dental procedures for bonding orthodontic brackets, dental veneers, and other restorations. The fast curing time and durability are key benefits in these applications.

9. DIY and Craft Projects: Due to its ease of use and effectiveness, UV glue is also popular in DIY projects and crafts, including model making, jewelry repair, and furniture assembly.

10. Sealing and Encapsulation: UV adhesive is used for sealing and encapsulating electronic components, protecting them from moisture, dust, and mechanical damage.

2. Consumer Electronics: UV glue is employed in the assembly of various consumer electronics, including smartphones, tablets, and televisions. It is used for bonding screens, lenses, and other components due to its clear finish and strong bond.

3. Medical Devices: In the medical industry, UV glue is utilized for assembling disposable and reusable medical devices. Its biocompatibility, strong adhesion, and fast curing time make it suitable for producing syringes, catheters, tube sets, and other medical equipment.

4. Automotive: UV-curing adhesives are used in the automotive industry for bonding sensors, headlamps, and plastic components. Their resistance to temperature and moisture makes them particularly useful in vehicles.

5. Optical and Photonics: UV glue is critical in the production of optical devices, including lenses, prisms, and fiber optic components. It ensures precise alignment and bonding without affecting the optical properties of components.

6. Jewelry Making: In the field of jewelry making, UV glue is used to bond gems and other decorative elements to metal substrates. Its clear finish and strong bond make it ideal for this application.

7. Packaging: For packaging applications, especially in the cosmetics industry, UV glue is used to assemble plastic packaging, secure labels, and bond decorative elements. Its rapid curing time improves production efficiency.

8. Dental Applications: UV-curing adhesives are used in dental procedures for bonding orthodontic brackets, dental veneers, and other restorations. The fast curing time and durability are key benefits in these applications.

9. DIY and Craft Projects: Due to its ease of use and effectiveness, UV glue is also popular in DIY projects and crafts, including model making, jewelry repair, and furniture assembly.

10. Sealing and Encapsulation: UV adhesive is used for sealing and encapsulating electronic components, protecting them from moisture, dust, and mechanical damage.

Hot Searches