prolong the service life of the die,

improve the flexibility and efficiency

of the machine tool processing.

|

Standard Equipment

|

Optional Equipment

|

|

O-type welded rigid integral frame

|

GENUO or Siemens CNC Control

|

|

Rexroth CNC Control and servo system

|

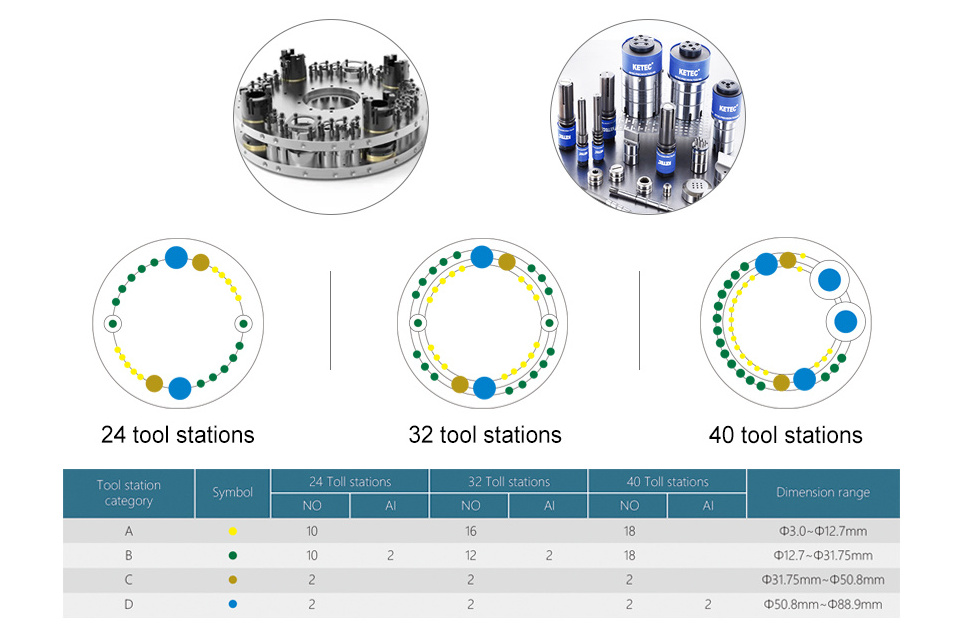

42 Station (Dual Circle+T die base)

|

|

24 Full-automatic indexing stations

|

Clamp Stripping Protection

|

|

Brush and ball mixed worktable

|

Scrap Collection Device

|

|

Auto feeding system with high-precision

|

Automatic Loading and Unloading

|

|

Precision wear-resistant turret and tools

|

Special thick turrent tooling

|

|

Floatable Pneumatic Clamps

|

Large seamless worktable

|

|

Bearing,timing belt,drag chain from DE

|

Peripheral light curtain protective fence

|

|

Schneider electrical parts from FR

|

Vacuum waste suction device

|

|

Automatic central lubrication system

|

Optional customized colors

|

|

Parameter name

|

|

Unit

|

ES30 Electric servo turret punch press

|

|

||||

|

Max sheet size

( including one-time repositioning )

|

|

mm

|

1250x5000

|

1500x5000

|

||||

|

Max impulse pressure

|

|

kN

|

300

|

|

||||

|

Thickness of processed plate

|

|

mm

|

4

|

|

||||

|

Max punch diameter

|

|

mm

|

φ88.9

|

|

||||

|

Workstation

|

|

No.

|

32

|

|

||||

|

Rotation number

|

|

No.

|

2( up to 4 )

|

|

||||

|

Max piercing diameter of rotary die

|

|

mm

|

φ50.8

|

|

||||

|

Punching accuracy

|

|

mm

|

±0.075

|

|

||||

|

Stamping

Times

|

Marking offset

|

hpm

|

1500

|

|

||||

|

|

Max impulse 1mm step 6mm stroke

|

hpm

|

750

|

|

||||

|

|

Max impulse 25.4mm step distahce, 6mm stroke

|

hpm

|

350

|

|

||||

|

Max feeding speed of sheet

|

|

m/min

|

X=96

|

Y=96

|

||||

|

Turret speed

|

|

r/min

|

30

|

|

||||

|

Number of control axes

|

|

No.

|

4

|

|

||||

|

Power

|

|

kW

|

20

|

|

||||

|

Air pressure

|

|

Mpa

|

0.5~0.6

|

|

||||

|

Overall

Dimensions

|

Long

|

mm

|

5500

|

6100

|

||||

|

|

Width

|

mm

|

5050

|

5050

|

||||

|

|

High

|

mm

|

2300

|

2300

|

||||

|

|

Weight

|

t

|

About 16

|

About 18

|

||||

|

The above data is only for reference only,to prevail in kind. More specifications available. Please

click here!

|

|

|

|

|

||||