- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.6mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

10000x2300x2200mm

-

Weight:

-

11000 kg

-

Feeding width:

-

914mm

-

Marketing Type:

-

New Product 2022

-

Frame Design:

-

Iron cast/steel plate

-

Roll Stations:

-

14-20 roller stations

-

Shafts Diameter:

-

70-80mm

-

Main Motor Power:

-

13kw

-

Hydraulic Power:

-

5.5kw

-

Material of Cutting Blade:

-

Cr12, Heat Treatment

-

Control System:

-

PLC(detla) System

-

Machine Structure:

-

350H Steel Welding

-

Forming Speed:

-

10-20m/min

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.8-1.6mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

10000x2300x2200mm

-

Weight:

-

11000 kg

-

Feeding width:

-

914mm

-

Marketing Type:

-

New Product 2022

-

Frame Design:

-

Iron cast/steel plate

-

Roll Stations:

-

14-20 roller stations

-

Shafts Diameter:

-

70-80mm

-

Main Motor Power:

-

13kw

-

Hydraulic Power:

-

5.5kw

-

Material of Cutting Blade:

-

Cr12, Heat Treatment

-

Control System:

-

PLC(detla) System

-

Machine Structure:

-

350H Steel Welding

-

Forming Speed:

-

10-20m/min

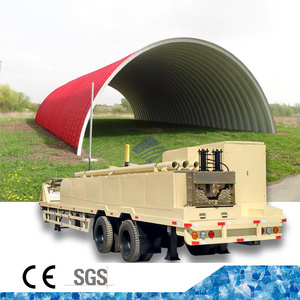

Product Certification

CE Certified.Valid from 2020-07-18 until 2025-07-18

Packaging & Delivery

Selling Units: Single item

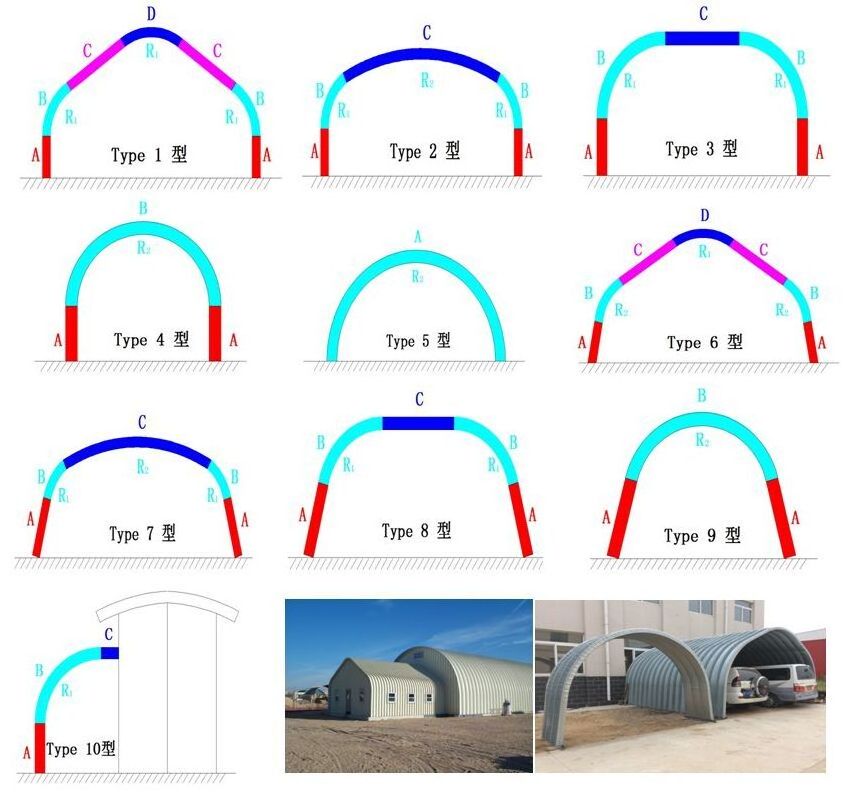

Parameters of the Machine:

Size: 10000mm * 2300mm * 2200mm

Wight: 11t

Drive System: Electric

Electric Standard: 380v, 50hz, 3 phase

Total Power: 18.5kw

Forming Power: 7.5kw

Cutting Power: 4.0kw

Bending Power: 4.0kw

Conical Power: 3.0kw

Step of Rollers: 13 Steps

Material of Rollers: 45# Steel, quenched HRC 58-62

Material of Shafts: 45# Steel, quenched HRC 58-62

Material of Cutting Blade: Cr12MoV Steel

Type of Cutting System: Hydraulic

Material of Bending Leaves: Stainless Steel

Forming Speed: 15m/min

Bending Speed: 13m/min

Seaming Speed: 6 - 8m/min

Control System: PLC (Omron)

Uncoiler Capacity: About 6000kg

Machine Features

1. More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated

to ensure that customers can get qualified products at the same time, it can avoid the scratch of the

color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

Factory view

Why Choose Us?

1) We have sold more than 5000 sets roll forming machines to many countries around the world.

2) We have hundreds of models about all kinds of roll forming machine for your reference, you donot worry of you do not have a profile drawing, We can recommond you some classical models that is common in your country.

3) When designing the macine, our considerate service will estimate and avoid the problem that may happen.

4) One set machine can provide many solutions with different price level.But they are all cost-effective.

5) We attach importance to many detailes,Every machine part quality is higher than our competitors in same price level.