- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

2mm

-

Voltage:

-

380V/220V,50Hz/60Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jinri packaging machinery

-

Dimension(L*W*H):

-

2100mm*1450mm*2250mm

-

Weight:

-

2000 KG

-

Product Name:

-

can filling machine

-

filling method:

-

isobaric

-

material:

-

SUS304/316

-

Capacity:

-

2000CPH

-

Bottle Volume:

-

200ml-1L

-

Customizable:

-

yes

-

After Warranty Service:

-

Video technical support

-

Processing Types:

-

Rinsing,Filling,Capping

-

Packaging:

-

Film and Wooden Case

-

Certification:

-

CE ISO

Quick Details

-

Machinery Capacity:

-

1000CPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Beer

-

Filling Accuracy:

-

2mm

-

Voltage:

-

380V/220V,50Hz/60Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Jinri packaging machinery

-

Dimension(L*W*H):

-

2100mm*1450mm*2250mm

-

Weight:

-

2000 KG

-

Product Name:

-

can filling machine

-

filling method:

-

isobaric

-

material:

-

SUS304/316

-

Capacity:

-

2000CPH

-

Bottle Volume:

-

200ml-1L

-

Customizable:

-

yes

-

After Warranty Service:

-

Video technical support

-

Processing Types:

-

Rinsing,Filling,Capping

-

Packaging:

-

Film and Wooden Case

-

Certification:

-

CE ISO

Zhangjiagang Jinri Packaging Machinery Co., Ltd.

Zhangjiagang Jinri Packaging Machinery Co., Ltd.

is a professional manufacturer of beverage machinery in China.Our main products have: Water filling production line, juice filling production line, carbonated drinks filling production line, and also aerosol filling machine, 5 Gallon bottle filling production line, and all other auxiliary equipment.

Our engineers are located all over the world and can provide safe and fast service to your beverage production solutions in your country.

Product Description

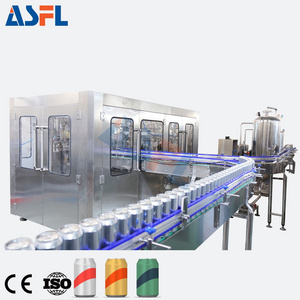

BGF12-1 Beer Can Filling Machine

Automatic glass bottle Soft drinks rinser filler capper 3-in-1 filling Triblock, combined with rinsing, filling and capping. It is innovated and designed in the requirement of carbonated soft drinks, beer, energy drink, and soda water, on the basis of introducing, digesting and absorbing advanced technology from Germany.

The machine is a full-automatic multiple-function washing, filling and capping unit. It is used in washing. filling and sealing all kinds of carbonated drinks such as beer, soft drink, energy drink mineral water and pure water. The line has features of unique design,new style, complete functions,multi-purpose, convenient in operation, compact construction, high automaticity. It is the best filling equipment in China.

The machine is a full-automatic multiple-function washing, filling and capping unit. It is used in washing. filling and sealing all kinds of carbonated drinks such as beer, soft drink, energy drink mineral water and pure water. The line has features of unique design,new style, complete functions,multi-purpose, convenient in operation, compact construction, high automaticity. It is the best filling equipment in China.

1. Can Stacker.

1-PLC control of the whole machine, fully automatic operation;-Adapt to various stack types and bottle types, easy to adjust;

2-Segmented transmission with high-quality conveyor chain, the output section can be arbitrarily lengthened;

3-Using 304 material, the whole machine is beautiful and elegant;

2-Segmented transmission with high-quality conveyor chain, the output section can be arbitrarily lengthened;

3-Using 304 material, the whole machine is beautiful and elegant;

2. Washing Part

1

-Scope of application: water spraying and drying on the slope of the tin can.

2-water spraying box made by stainless steel structure.

3-the built-in ¢32 mm stainless steel spray pipe, divide into two segments, hot and cold water tank temperature higher than 85 degrees.

4-tank cage, by ¢article 8 mm stainless steel.

5-the support frame is composed of 50mm x 50mm x 2mm stainless steel square pipe.

2-water spraying box made by stainless steel structure.

3-the built-in ¢32 mm stainless steel spray pipe, divide into two segments, hot and cold water tank temperature higher than 85 degrees.

4-tank cage, by ¢article 8 mm stainless steel.

5-the support frame is composed of 50mm x 50mm x 2mm stainless steel square pipe.

3.New type filling valve.

1-Large flow filling valve, filling flow up to 125ml/s

2-When filling,ensure that the filling valve and the can are completely sealed, maintain the isobaric environment, ensure the liquid level is accurate

3- 304/316 stainless steel filling pump

4- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean - Efficient spray nozzle rinse thoroughly and save water for flushing

2-When filling,ensure that the filling valve and the can are completely sealed, maintain the isobaric environment, ensure the liquid level is accurate

3- 304/316 stainless steel filling pump

4- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean - Efficient spray nozzle rinse thoroughly and save water for flushing

Specification

|

Model

|

Filling heads

|

Capping heads

|

Capacity(BPH)

|

Motor Power(KW)

|

Dimension(mm)

|

Weight(kg)

|

|

YDL4-4-1

|

4

|

7

|

1000

|

2.2

|

2000X700X2250

|

2300

|

|

YDL12-1

|

12

|

1

|

1500

|

2.2

|

2500X1800X2300

|

3500

|

|

YDL12-4

|

12

|

4

|

4000

|

3

|

2800X2100X2300

|

5100

|

|

YDL18-4

|

18

|

4

|

9000

|

3

|

3500X2200X2300

|

7300

|

|

YDL20-4

|

20

|

4

|

12000

|

3

|

4700X2800X2050

|

9600

|

|

YDL30-6

|

30

|

6

|

16000

|

4

|

5460X3300X2700

|

12500

|

|

YDL40-6

|

40

|

6

|

20000

|

5.5

|

5556X4239X2950

|

16200

|

One partner for all your needs.

A complete CSD line solution from Jinri Packaging Machinery takes into account every step of your PET carbonated soft drink process, from minimising resource waste to determining your bottle's ideal look and weight. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment,fast ramp-up and beyond.

A complete CSD line solution from Jinri Packaging Machinery takes into account every step of your PET carbonated soft drink process, from minimising resource waste to determining your bottle's ideal look and weight. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment,fast ramp-up and beyond.

Palletizer and depalletizer.

Filling Machine.

Spray pasteurization tunnel.

Bottle dryer machine.

Labeling Machine.

Packing System.

Hot Searches