- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

DN 15700mm

-

Capacity:

-

2000m3

-

Weight:

-

270MT

-

Design Pressure(MPa):

-

1.73 MPa

-

Design Standard:

-

ASME

-

Working Temperature(℃):

-

-20 - 50 ℃

-

Filling Medium:

-

LPG

-

Payload:

-

500MT

-

Corrosion Allowance:

-

1.0mm

-

Joint Efficiency:

-

1.0

-

After-sales Service Provided:

-

Field maintenance and repair service

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

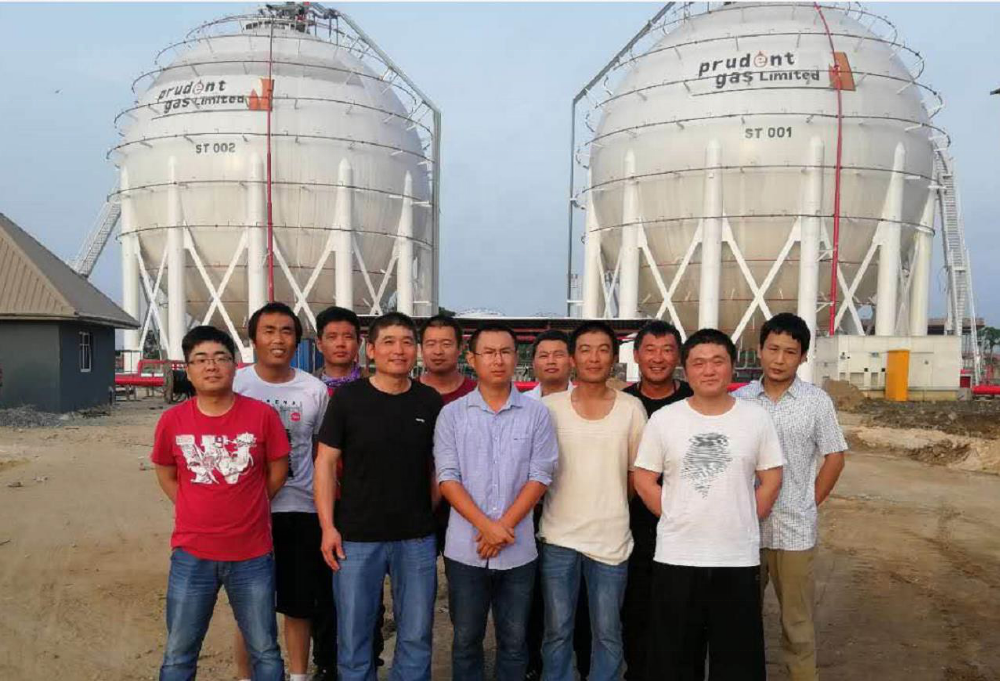

Nigeria

Quick Details

-

Max Working Pressure(MPa):

-

1.73 MPa

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

HONGTU

-

Dimension(L*W*H):

-

DN 15700mm

-

Capacity:

-

2000m3

-

Weight:

-

270MT

-

Design Pressure(MPa):

-

1.73 MPa

-

Design Standard:

-

ASME

-

Working Temperature(℃):

-

-20 - 50 ℃

-

Filling Medium:

-

LPG

-

Payload:

-

500MT

-

Corrosion Allowance:

-

1.0mm

-

Joint Efficiency:

-

1.0

-

After-sales Service Provided:

-

Field maintenance and repair service

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Nigeria

Products Description

HONGTU

has the design and fabrication capability of large ASME codes spherical tanks and owns 5 sets of large hydraulic pressing machine. The maximum pressing capacity for spherical shell plate is 80mm. Besides, HONGTU can also construct the spherical tanks made of special steel such as stainless steel, stainless steel clad carbon steel plate, 9Ni steel and etc., and owns relevant project references.

Product Parameters

|

Design Code:

ASME BPVC VIII-1/VIII-2, GB/T 12337, JB/T 4732

Vessel Capacity:

50m³~10000m³ Liquid Gas Spherical Tank, 200m³~20000m³ Gas Spherical Tank.

Vessel Material:

SA-516, SA-537 CL1, SA-537 CL2, Q370R, etc.

|

|

|

|

|

|

|

||||||

|

Design Standard

|

ASME VIII-2

|

|

|

|

|

|

||||||

|

Total Capacity m³

|

1500

|

2000

|

3000

|

5000

|

6000

|

8000

|

||||||

|

Medium

|

LPG

|

LPG

|

LPG

|

LPG

|

LPG

|

LPG

|

||||||

|

*Payload KG

|

750

|

1000

|

1500

|

2500

|

3000

|

4000

|

||||||

|

Shell Material

|

SA516M

|

SA537 CL.1

|

SA537 CL.1

|

SA537 CL.2

|

SA537 CL.2

|

SA537 CL.2

|

||||||

|

Filling Ratio

|

0.85

|

0.9

|

0.9

|

0.9

|

0.9

|

0.9

|

||||||

|

Tank Net Weight KG

|

258610

|

288617

|

431223

|

636868

|

732400

|

893620

|

||||||

|

Design Pressure MPa

|

1.77

|

1.77

|

1.77

|

1.8

|

1.77

|

1.42

|

||||||

|

Working Pressure MPa

|

1.57

|

1.4

|

1.57

|

1.7

|

1.57

|

1.2

|

||||||

|

MAWP MPa

|

1.77

|

1.77

|

1.77

|

1.8

|

1.77

|

1.42

|

||||||

|

Design Temperature ℃

|

-20/50

|

-20/50

|

-20/50

|

-40/50

|

50

|

-30/50

|

||||||

|

Working Temperature

℃

|

-18/40

|

35

|

-15~40

|

-35~40

|

40

|

-15/40

|

||||||

|

Corrosion Allowance MM

|

1.0

|

1.5

|

1.5

|

1.5

|

1.0

|

2.0

|

||||||

|

NDT

|

YES

|

YES

|

YES

|

YES

|

YES

|

YES

|

||||||

|

Hydraulic Test Pressure MPa

|

2.53

|

2.54

|

2.54

|

2.58

|

2.54

|

2.04

|

||||||

|

Air Tightness Test Pressure MPa

|

1.77

|

1.77

|

1.77

|

1.8

|

1.77

|

1.42

|

||||||

|

PWHT

|

YES

|

YES

|

YES

|

YES

|

YES

|

YES

|

||||||

|

Wind Pressure Pa

|

1035

|

1500

|

1500

|

2000

|

1500

|

3200

|

||||||

|

Snow Pressure Pa

|

--

|

--

|

--

|

300

|

--

|

--

|

||||||

|

Seismic Intensity

|

7 Degree

|

7 Degree

|

7 Degree

|

8 Degree

|

8 Degree

|

8 Degree

|

||||||

|

Field Soil Category

|

II

|

II

|

II

|

II

|

II

|

II

|

||||||

|

*Please note that different medium component will cause different density and different payload.

**Please contact for more different kinds of capacity and standard tanks.

|

|

|

|

|

|

|

||||||

|

Design Standard

|

ASME VIII-1

|

|

ASME VIII-2

|

|

||||

|

Total Capacity m³

|

600

|

974

|

2000

|

2000

|

||||

|

Medium

|

C4

|

Isobutane

|

Ethylene

|

Ethane

|

||||

|

*Payload KG

|

278400

|

1809

|

1012600

|

747000

|

||||

|

Filling Ratio

|

0.8

|

0.9

|

0.83

|

0.83

|

||||

|

Material

|

SA537 CL.2

|

SA516M GR485

|

SA203 GR.F

|

SA203 GR.F

|

||||

|

Net Weight KG

|

69628

|

109500

|

374367

|

399963

|

||||

|

Design Pressure MPa

|

0.7/-0.03

|

0.79

|

1.98

|

2.15

|

||||

|

Working Pressure MPa

|

0.47

|

0.6

|

1.65

|

1.775

|

||||

|

Design Temperature ℃

|

-39/65

|

-20/50

|

120

|

120

|

||||

|

Working Temperature ℃

|

42.5

|

40

|

-50~-10

|

-50~-10

|

||||

|

Corrosion Allowance MM

|

2.5

|

1.5

|

4.0

|

4.0

|

||||

|

Wind Pressure Pa

|

600

|

800

|

300

|

300

|

||||

|

Snow Pressure Pa

|

400

|

0

|

1800

|

1800

|

||||

|

Seismic Intensity

|

7 Degree

|

8 Degree

|

6 Degree

|

6 Degree

|

||||

|

Field Soil Category

|

II

|

II

|

II

|

II

|

||||

|

*Please note that different medium component will cause different density and different payload.

**Please contact for more different kinds of capacity and medium tanks.

|

|

|

|

|

||||

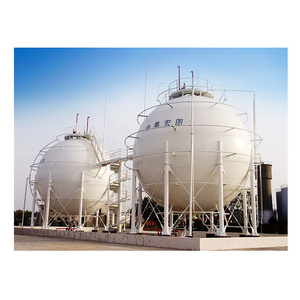

Product Pictures

Tank Shell Pressing

Tank Shell Cutting

Factory Assembly Welding

Field Assembly

Field Assembling Welding

Heat Treatment

Pressure Test and Air Tightness Test

LPG Receiving Terminal

Based on collectivized operation and business synergy pattern and its own equipment manufacturing advantages,

HONGTU

is committed to providing global customers with integrated LPG engineering solutions, engineering services giving priority to engineering design and EPC services, and providing integrated services of system design, key equipment manufacturing, onsite installation and commissioning, personnel training and operation technical support.

Product Packages & Delivery

Certificate

ASME U Certificate

ASME U2 Certificate

Certificate of Authorization to Register NB

Container Factory Approval Certificate

BVCT 1681762/S

ADR 2017

GB/T28001-2011/OHSAS18001:2007

OCCUPATIONAL HEALTH AND SAFETY MANAGEMENT SYSTEM CERTIFICATE

GB/T19001-2016/ISO9001:2015

QUALITY MANAGEMENT SYSTEM CERTIFICATE

GB/T24001-2016/ISO14001:2015

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE

SY/T6276-2014, Q/SY1002.1-2003, Q/SHS0001.1-2001

HSE MANAGEMENT SYSTEM CERTIFICATE

Manufacture License of Special Equipment

Pressure Vessel

Design License of Special Equipment

Pressure Vessel

Design License of Special Equipment

Pressure Pipe

Hot Searches