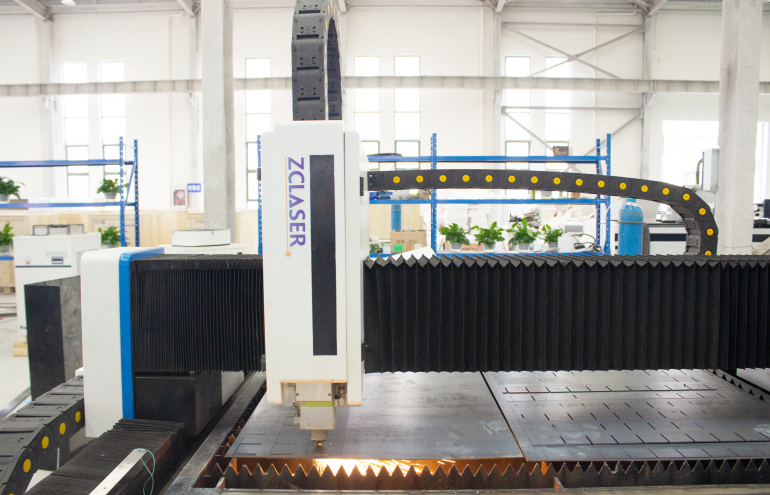

Compared with other fiber laser machines, this machine has a smaller working format and higher cutting precision, which is suitable for high-quality batch cutting of metal plates. The machine can cut steel, stainless steel, copper, aluminum, silver, gold and other metal materials, and the cutting surface is smooth and flat. It has been welcomed by the majority of jewelry industry workers for a long time.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut/X3000

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

Depended by power

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZCLASER

-

Weight (KG):

-

2500 KG

-

Core Components:

-

Laser source

-

Product name:

-

Laser Cutting Machine

-

Laser type:

-

Fiber laser

-

Laser power:

-

1000W /1500W/ 2000W/ 3000W/6000W/8000W/10000W/12000W/20000W

-

Cooling System:

-

Water Cooling

-

Application material:

-

Aluminum Copper SS

-

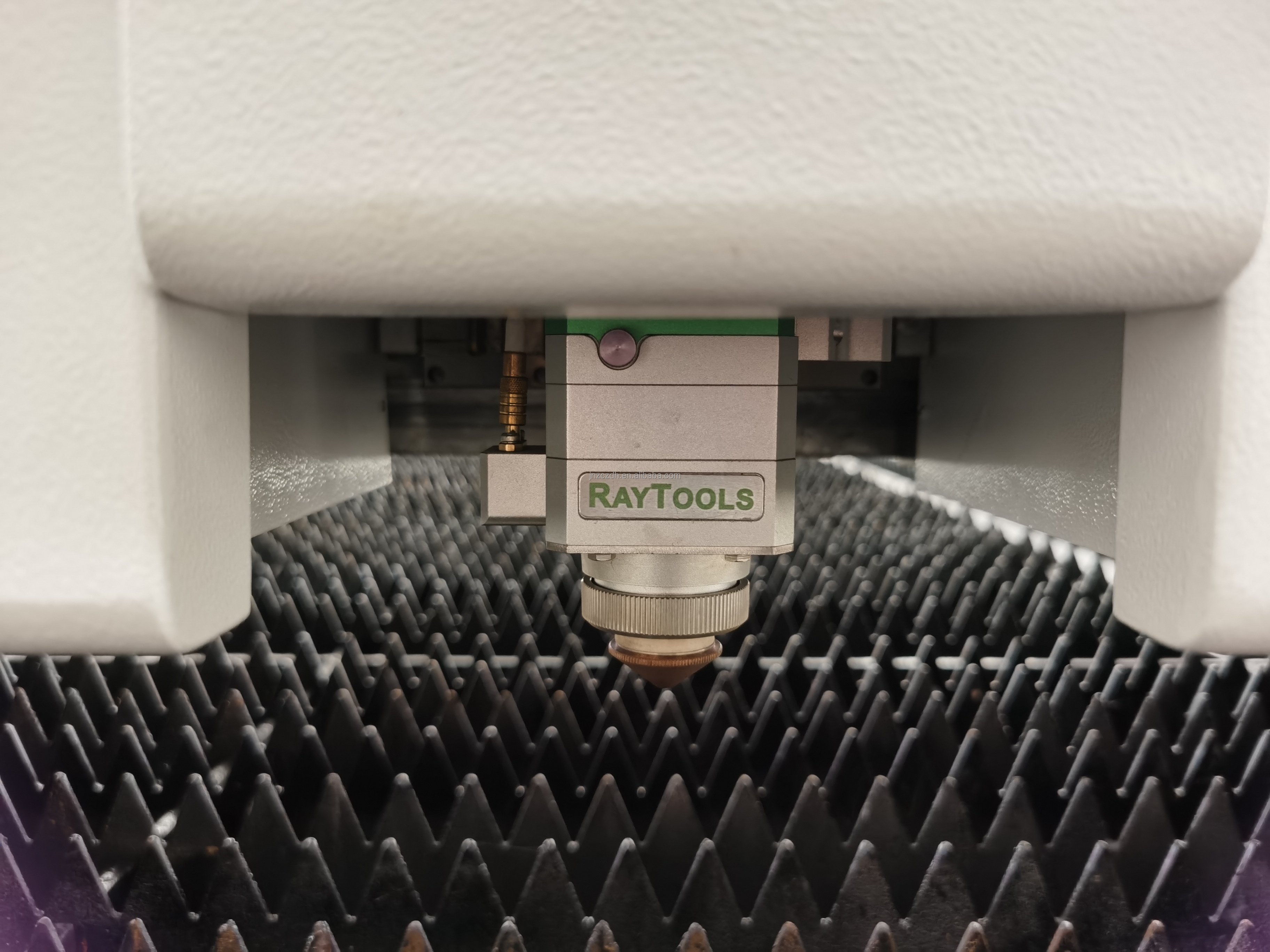

Laser head:

-

Raytools Cutting Head

-

Laser source:

-

IPG Raycus MAX JPT

-

Control system:

-

Cypcut System

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Working Voltage:

-

220v-380v/50-60HZ

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut/X3000

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

Depended by power

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZCLASER

-

Weight (KG):

-

2500 KG

-

Core Components:

-

Laser source

-

Product name:

-

Laser Cutting Machine

-

Laser type:

-

Fiber laser

-

Laser power:

-

1000W /1500W/ 2000W/ 3000W/6000W/8000W/10000W/12000W/20000W

-

Cooling System:

-

Water Cooling

-

Application material:

-

Aluminum Copper SS

-

Laser head:

-

Raytools Cutting Head

-

Laser source:

-

IPG Raycus MAX JPT

-

Control system:

-

Cypcut System

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Working Voltage:

-

220v-380v/50-60HZ

Product Description

High Precision Fiber Laser Cutting Machine Features:

Compared with other fiber laser machines, this machine has a smaller working format and higher cutting precision, which is suitable for high-quality batch cutting of metal plates. The machine can cut steel, stainless steel, copper, aluminum, silver, gold and other metal materials, and the cutting surface is smooth and flat. It has been welcomed by the majority of jewelry industry workers for a long time.

Why Choose Fiber Laser Cutting Machine?

★

Narrow cutting slit with good cutting accuracy

★

Fast cutting speed and small heat-affected zone

★

G

ood quality of the laser cut surface, with vertical cut edges and smooth cut edges, which can be directly welded without correction

★

No mechanical stress on the cutting edge, no shear burrs and no chips

★

Laser cutting does not have the phenomenon of tool loss and contact energy loss, no need to replace the tool

★

N

o inertia of the beam, allowing for high-speed cutting

Specifications

|

Model

|

ZCGX-3030

|

|

|

Laser Type

|

Fiber Laser Source

|

|

|

Wave Length

|

1080 nm

|

|

|

Laser Power

|

1000W 1500W 2000W

|

|

|

Beam Quality

|

<0.373mrad

|

|

|

Effective Cutting Range

|

300*300mm

|

|

|

Axial Positioning Accuray Of Table

|

≤±0.01mm

|

|

|

Table Repeatability Accuracy

|

≤±0.01mm

|

|

|

Workbench Maximum Load

|

800KG

|

|

|

Electricity Demand

|

380V/50Hz/100A

|

|

|

|

||

Main Parts

Autofocus Cutting Head

Auto-focus laser head-no manual operation is required, and the vertical height is automatically controlled, so as to realize the cutting operation of different sheet thicknesses.

Raycus Laser Generator

It has higher photoelectric conversion efficiency, better and more stable beam quality, and stronger anti-high-reflection ability.

It introduces an optimized optical fiber transmission system.

It introduces an optimized optical fiber transmission system.

Cypone Control System

The display operation unit provides good man-machine interface to display various operation information, and the operation panelwith function keys for machine operation.

S&A Water Cooler

1. The temperature control accuracy can reach ±0.5℃.

2. It has two temperature control modes, which are suitable for different use occasions; it has a variety of settings and fault display functions.

Panasonic

Servo Driver

Japan

Panasonic

servo drive system guarantees the working stability and accuracy. It ensures the accuracy of the machine working for a long time

Servo Motor

By adding and improving vibration suppression function, it can improve the following performance and shorten the setting time.

Automatic Rail Lubrication System

The frequency of use can be set by adjusting the parameters through the computer.

Pneumatic Components - Japan SMC

Can easily adjust the air pressure ratio.

Samples

Material:

Suitable for cutting of stainless steel, iron sheet, aluminum, copper, alloy, steel, diamond equivalent materials or dissimilar materials

Industry:

Household hardware, kitchenware and bathroom, stainless steel door handles, electronic components, sensors, clocks, fine machinery, communications, handicrafts and other industries, automotive hydraulic tappets and other industries with high strength

|

Carbon Steel

|

1000W

|

1500W

|

2000W

|

3000W

|

|

Thickness

|

Speed m/min

|

Speed m/min

|

Speed m/min

|

Speed m/min

|

|

1

|

8.0-10

|

8.0-10

|

8.0-10

|

8.0-10

|

|

2

|

4.5-7.0

|

4.5-7.0

|

4.7-7.0

|

4.8-7.5

|

|

3

|

2.4-3.0

|

2.6-4.0

|

3.0-4.8

|

3.3-5.0

|

|

4

|

2.0-2.4

|

2.5-3.0

|

2.8-3.5

|

3.0-4.2

|

|

5

|

1.5-2.0

|

2.0-2.5

|

2.2-3.0

|

2.6-3.5

|

|

6

|

1.4-1.6

|

1.5-2.2

|

1.8-2.6

|

2.3-3.2

|

|

8

|

0.8-1.2

|

1.0-1.4

|

1.2-1.8

|

1.8-2.6

|

|

10

|

0.6-1.0

|

0.8-1.1

|

1.1-1.3

|

1.2-2.0

|

|

12

|

0.5-0.8

|

0.7-1.0

|

0.9-1.2

|

1.0-1.6

|

Package and delivery

Package

We have

3

layers package.

1.For the outside, we adopt plywood case.

2.In the middle, the machine is covered by foam, to protect the machine from shaking.

3.For the inside layer, the machine is covered by the waterproof plastic bag.

2.In the middle, the machine is covered by foam, to protect the machine from shaking.

3.For the inside layer, the machine is covered by the waterproof plastic bag.

Delivery Time

Within

15

working days after receiving the advance payment. Detail delivery date should be decided according to actual machine's specification.

Hot Searches