Graphite chill block, its main principle of use is that graphite chill material has the advantages of light specific gravity, high

fire resistance, high thermal conductivity and so on. Therefore, using graphite chill as a refrigerant instead of metal chill can

better solve the problems of porosity and shrinkage of castings such as cast steel, cast copper and cast aluminum, and can

effectively solve the casting defects such as white mouth and porosity caused by the use of metal chill.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MUZI CARBON

-

Model Number:

-

MZ-GC

-

Product name:

-

graphite Chill Blocks Bricks

-

Color:

-

Black

-

Dimensions:

-

Customers' Requirement

-

ASH:

-

0.1% Max

-

Raw Material:

-

High purity graphite

-

Material:

-

100% Petroleum Coke

-

Certificate:

-

ISO9001

-

HS CODE:

-

8545900000

-

MOQ:

-

1 Tons

-

Applicattion:

-

Foundry metal casting cooling

Quick Details

-

Application:

-

Foundry metal casting cooling

-

Chemical Composition:

-

Graphite

-

Place of Origin:

-

Inner Mongolia, China

-

Brand Name:

-

MUZI CARBON

-

Model Number:

-

MZ-GC

-

Product name:

-

graphite Chill Blocks Bricks

-

Color:

-

Black

-

Dimensions:

-

Customers' Requirement

-

ASH:

-

0.1% Max

-

Raw Material:

-

High purity graphite

-

Material:

-

100% Petroleum Coke

-

Certificate:

-

ISO9001

-

HS CODE:

-

8545900000

-

MOQ:

-

1 Tons

-

Applicattion:

-

Foundry metal casting cooling

Product Description

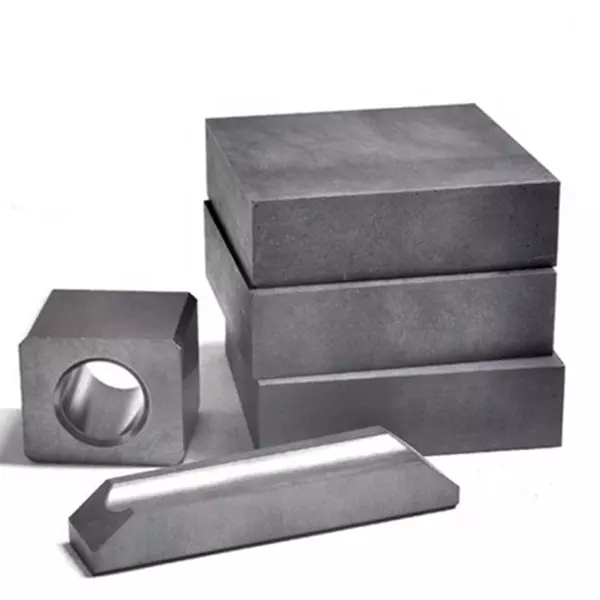

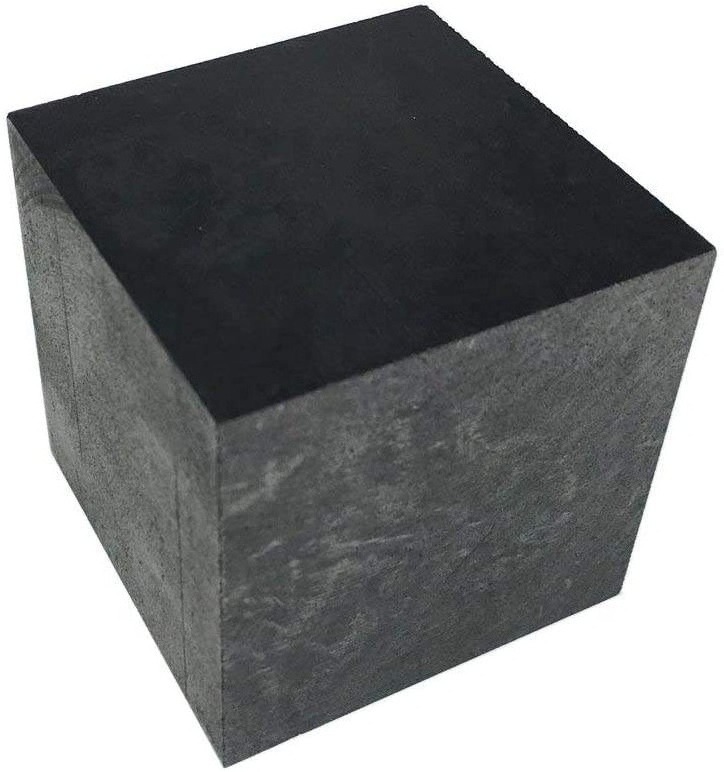

Graphite chill blocks

Graphite chill applications

1. The feed riser is not easy to shrink.

2. Prevent excessive wall thickness and rapid change of crack location.

3. The use of risers can improve the sequential solidification state of castings, extend the feed distance of risers, and reduce the number or size of risers.

4. Using cold iron to accelerate the cooling of each hot section can not only prevent or reduce the casting deformation, but also optimize the production process, and the whole casting is close to solidification.

5. Reduce and prevent insulation of thick wall castings. The cooling effect of cast iron is to accelerate the cooling rate of some parts of cast iron.

4. Using cold iron to accelerate the cooling of each hot section can not only prevent or reduce the casting deformation, but also optimize the production process, and the whole casting is close to solidification.

5. Reduce and prevent insulation of thick wall castings. The cooling effect of cast iron is to accelerate the cooling rate of some parts of cast iron.

|

density

|

≥1.65

|

|

ash

|

<0.5

|

|

S

|

<0.05

|

|

weight

|

3.22-3.38kg

|

Company profiles

Muzi carbon company was founded in 1996,located in Xingwangjiao industrial park area B,Xinghe county,Ulanqab city,Inner

Mongolia.The registered capital is thirty million Yuan.The company covers a total area of 700 mu nearly.The total number of

employees is 508.The company has four international trade companies,four production companies,a research institute,a technology

center,a staff training center and eighteen functional departments. The company is a national high-tech enterprise,the council

member of Chinese Carbon Industry Association.The company has been focused on the research,production and sale of the

carbon-graphite material,fine finishing graphite product,carbon-based composite material.Products are sold to over 20

provinces,the customers are nearly 400 in China.We export the products over 60 countries and regions in Europe,America and

Southeast Asia.

Mongolia.The registered capital is thirty million Yuan.The company covers a total area of 700 mu nearly.The total number of

employees is 508.The company has four international trade companies,four production companies,a research institute,a technology

center,a staff training center and eighteen functional departments. The company is a national high-tech enterprise,the council

member of Chinese Carbon Industry Association.The company has been focused on the research,production and sale of the

carbon-graphite material,fine finishing graphite product,carbon-based composite material.Products are sold to over 20

provinces,the customers are nearly 400 in China.We export the products over 60 countries and regions in Europe,America and

Southeast Asia.

Packing & Delivery

Advantages:

1. Low electric resistance

2. High temperature resistance

3. Good electric and thermal conductivity

4. High oxidation resistance

5. Greater resistance to thermal and mechanical shock

6. High mechanical strength and machining accuracy

7. Homogeneous structure

8. Hard surface and good flexural strength

1. Low electric resistance

2. High temperature resistance

3. Good electric and thermal conductivity

4. High oxidation resistance

5. Greater resistance to thermal and mechanical shock

6. High mechanical strength and machining accuracy

7. Homogeneous structure

8. Hard surface and good flexural strength

The application of graphite chilling block:

Graphite is usually used as chilling materials in metal casting for large casting products, because of its good thermal

conductivity and uniform & fast heat dissipation; graphite can also be used as casting molds for different casting process,

because of its high temperature resistance, good strength and hardness, and the characteristics of non-infiltration with metal

Graphite is usually used as chilling materials in metal casting for large casting products, because of its good thermal

conductivity and uniform & fast heat dissipation; graphite can also be used as casting molds for different casting process,

because of its high temperature resistance, good strength and hardness, and the characteristics of non-infiltration with metal

Main Types of materials :

1- Vibrated Graphite Blocks.

2- Molded Graphite Block.

3- Isostatic Graphite Blocks The sizes from 10mm—2300mm available, they could be customized.

Main Shape of Graphite Chilling products :

1-Graphite Brick or Graphite Block

2-Graphite plate

3-graphite rod

4-Customized Graphite mold shape

1- Vibrated Graphite Blocks.

2- Molded Graphite Block.

3- Isostatic Graphite Blocks The sizes from 10mm—2300mm available, they could be customized.

Main Shape of Graphite Chilling products :

1-Graphite Brick or Graphite Block

2-Graphite plate

3-graphite rod

4-Customized Graphite mold shape

FAQ

1. Delivery time?

The delivery time is around 20-30 days after receiving your deposit or L/C.

2. MOQ?

For trail order, we accept 1 pc.

3. Payment term?

30% deposit, balance against the BL copy; 100% L/C at sight

4. Production Capacity of our factory?

2000 MT per month.

The delivery time is around 20-30 days after receiving your deposit or L/C.

2. MOQ?

For trail order, we accept 1 pc.

3. Payment term?

30% deposit, balance against the BL copy; 100% L/C at sight

4. Production Capacity of our factory?

2000 MT per month.

Contact Info

Hot Searches