- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+-0.1%

-

Driven Type:

-

servo motor

-

Voltage:

-

can be customized

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BRIGHTWIN

-

Dimension(L*W*H):

-

1500*800*1800MM

-

Weight:

-

400 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

general

-

name:

-

nail polish bottle filling machine fully automatic

-

usage:

-

nail polish bottle filling machine fully automatic

-

material:

-

stainless steel 304/316

-

design:

-

according to products and sample bottles etc

-

engineer and technicians:

-

with over 15 years experience

-

only quick wear part:

-

seal ring

-

measuring:

-

piston pump

-

Keywords:

-

nail polish bottle filling machine fully automatic

Quick Details

-

Machinery Capacity:

-

Other, 6000BPH, 2000BPH

-

Packaging Material:

-

Glass, Plastic

-

Filling Material:

-

Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

+-0.1%

-

Driven Type:

-

servo motor

-

Voltage:

-

can be customized

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

BRIGHTWIN

-

Dimension(L*W*H):

-

1500*800*1800MM

-

Weight:

-

400 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

type:

-

general

-

name:

-

nail polish bottle filling machine fully automatic

-

usage:

-

nail polish bottle filling machine fully automatic

-

material:

-

stainless steel 304/316

-

design:

-

according to products and sample bottles etc

-

engineer and technicians:

-

with over 15 years experience

-

only quick wear part:

-

seal ring

-

measuring:

-

piston pump

-

Keywords:

-

nail polish bottle filling machine fully automatic

nail polish

bottle filling machine fully automatic

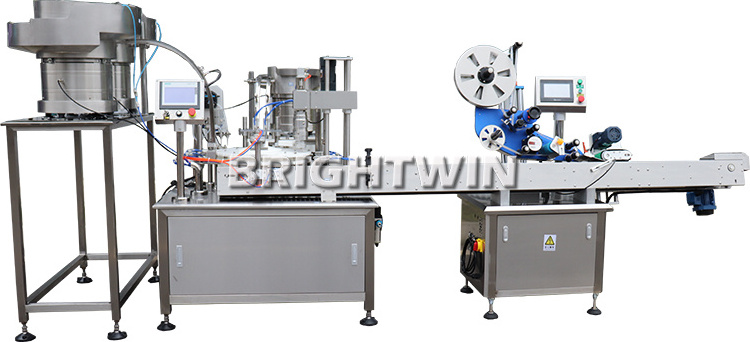

This machine is mainly applied to various material round bottle, flat bottles. Filling material could be small dose of medicine liquid, like syrup, essential oil, perfume, Royal jelly, oral liquid, face cream etc.

The machine finished all works of bottle feeding, filling, putting inner plug if there is and capping outer covers automatically.

It can be connected with other automatic machines to compose an automatic filling and packaging line, as:

The machine finished all works of bottle feeding, filling, putting inner plug if there is and capping outer covers automatically.

It can be connected with other automatic machines to compose an automatic filling and packaging line, as:

Some of samples

Deatails

1. Bottles feeding device

According to bottles' shape and capacity need can choose different feeding methods, like: unscrambler, elevator, vibrator, swing disc, etc.

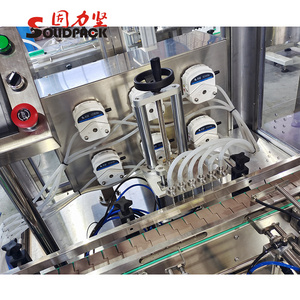

2. Filling part

According to the viscosity of the liquid, will adopt different filling methods, like: peristaltic pump, piston pump, etc. And filling nozzles numbers are based on filling volume and capacity need.

3. Plug feeding(If there are plugs)

According to plugs' shape and capacity need can choose different feeding methods, like: elevator, vibrator, etc.

4. Plugs inserting part

If there are plugs, the machine should add this part. According to the plugs' shape and capacity need to adopt different plugs placing method and plugging head number. Normally, punch or iron hand are available options.

5. Caps feeding device

According to caps' shape and capacity need can choose different feeding methods, like: elevator, vibrator, etc.

6. Capping part

According to the caps' shape and capacity need to adopt different caps placing method and capping head number. Normally, punch or

iron hand are available options.

iron hand are available options.

7. Labeling device

It's an optional device. It can be installed on star wheel or connect after the filling and capping machine. According to bottles' different shape and labels' position to choose different labeling type: standing round bottle labeling machine, standing double sides labeling machine, horizontal labeling, bottom labeling machine, etc.

Main features:

● High filling precision.

● Suitable for different bottle size, 0.5ml-100ml.

● The machine adopts full-auto PLC and human-computer touch screen control system.

● No bottles, stop filling.

● No bottles, No plunger and caps feeding.

● Magnetic moment capping, adjustable on pine, tight, do not hurt the jar and cover.

● Versatility, suitable for different specifications and bottle type, changing accessories convenient.

● Photoelectric detection devices make the machine realize down work to protection and automatic start up when lack of bottle or

more bottles and other working fault.

● Stepless speed regulation, the microcomputer, man-machine interface control, convenient operation adjustment.

● Mechnical arm take and put plug and cap, stable and very accurate.

● Suitable for different bottle size, 0.5ml-100ml.

● The machine adopts full-auto PLC and human-computer touch screen control system.

● No bottles, stop filling.

● No bottles, No plunger and caps feeding.

● Magnetic moment capping, adjustable on pine, tight, do not hurt the jar and cover.

● Versatility, suitable for different specifications and bottle type, changing accessories convenient.

● Photoelectric detection devices make the machine realize down work to protection and automatic start up when lack of bottle or

more bottles and other working fault.

● Stepless speed regulation, the microcomputer, man-machine interface control, convenient operation adjustment.

● Mechnical arm take and put plug and cap, stable and very accurate.

Technical Parameters

|

Filling material

|

Liquid/thick liquid/cream. etc

|

360cubes/min

|

540cubes/min

|

720cubes/min

|

|||

|

Filling method

|

peristaltic pump/piston pump. etc

|

2

|

3

|

4

|

|||

|

Filling nozzle number

|

1/2/4 etc, according to capacity request

|

|

|

|

|||

|

Capacity speed

|

20-200 bpm

|

|

|

|

|||

|

Suitable bottle size

|

customized

|

|

|

|

|||

|

Suitable caps

|

customized

|

|

|

|

|||

|

cap percent of pass

|

≥99%

|

|

|

|

|||

|

power

|

220V 50Hz

|

|

|

|

|||

|

power consumption

|

1.8Kw

|

|

|

|

|||

|

stand-lone noise

|

≤50dB

|

|

|

|

|||

|

Air consumption

|

0.36m³/min

|

|

|

|

|||

|

Weight

|

Approx. 800kg

|

|

|

|

|||

Our videos

Our service

Pre-Sales Service

* Inquiry and consulting support.

* Machine testing support.

* View our Factory.

* Machine testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

* Online technical support.

Hot Searches