- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

3.75KW

-

Dimension(L*W*H):

-

3000*1000*1900MM

-

Weight:

-

500 KG

-

Name:

-

Chinese Instant Noodle making machine Ramen noodles forming machine

-

Function:

-

Noodle making

-

Application:

-

Food Industry Machinery

-

Final product:

-

Instant noodle

-

Material:

-

Wheat flour

-

Color:

-

Silver

-

MOQ:

-

1set

-

After Warranty Service:

-

1year

-

Energy:

-

electric/steam

-

Shipping:

-

Sea

Quick Details

-

Production Capacity:

-

100-200kg per hour

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MT

-

Voltage:

-

380V

-

Power:

-

3.75KW

-

Dimension(L*W*H):

-

3000*1000*1900MM

-

Weight:

-

500 KG

-

Name:

-

Chinese Instant Noodle making machine Ramen noodles forming machine

-

Function:

-

Noodle making

-

Application:

-

Food Industry Machinery

-

Final product:

-

Instant noodle

-

Material:

-

Wheat flour

-

Color:

-

Silver

-

MOQ:

-

1set

-

After Warranty Service:

-

1year

-

Energy:

-

electric/steam

-

Shipping:

-

Sea

Automatic Chinese Instant Noodle making machine Ramen noodles forming machine is my company baaed on research of similar products at home and abroad, combined with the needs of the mass consumer

market in China, the development, Automatic Chinese Instant Noodle making machine Ramen noodles forming machine production of miniaturized production features a new generation of products. Perfect technology, compact structure, novel design, reliable performance.

Production from flour to finished products automatically once completed, the high degree of automation, simple operation, moderate yield, energy saving, small footprint,

the investment is only one tenth of large equipment, with less investment, quick features, particularly suitable for medium small and individual businesses.

Automatic Chinese Instant Noodle making machine Ramen noodles forming machine

of corrugated instant noodles,rehydration time is short,good elasticity,smoothness and transparency,comparable with large market populat equipment.

The Company is responsible for the installation, commissioning equipment, training staff until the production of qualified products; process recipe, spices, agents printed bags.

Voltage:Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

Product characteristics of Automatic Chinese Instant Noodle making machine Ramen noodles forming machine :

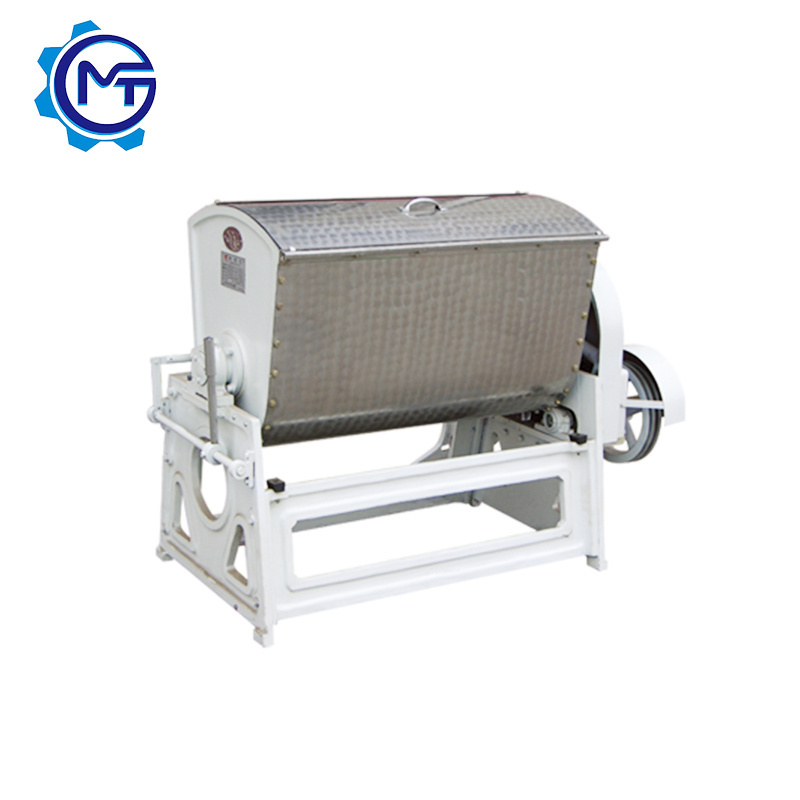

1. Mixing

Use a flour mixing machine to mix flour and water. The amount of water added per 1kg of flour is 0.3~0.4㎏. The temperature is

20-30°C, and the stirring time is 15-20 minutes. The dough produced in this process is called "dough", which is composed of a fine

mesh structure and forms the "glutinous" of the dough.

2. Compound

The formation of dough sheet. The dough is passed between the two rotating rolls to first make two dough sheets, and then combine

them into one. In this process, the dough sheet is made strong and uniform. Before the two dough pieces are combined, the dough is

sometimes aged for a period of time.

3. Calendering

Use a pressing roller to press a dough sheet with a thickness of about 10mm to make it thinner to about 1mm. In this process, the

mesh structure of the surface is strengthened to strengthen the "tendons"

4. Cutting

After pressing, the dough sheet enters the cutting stage. Rotate the cutter, and the noodles become noodles.

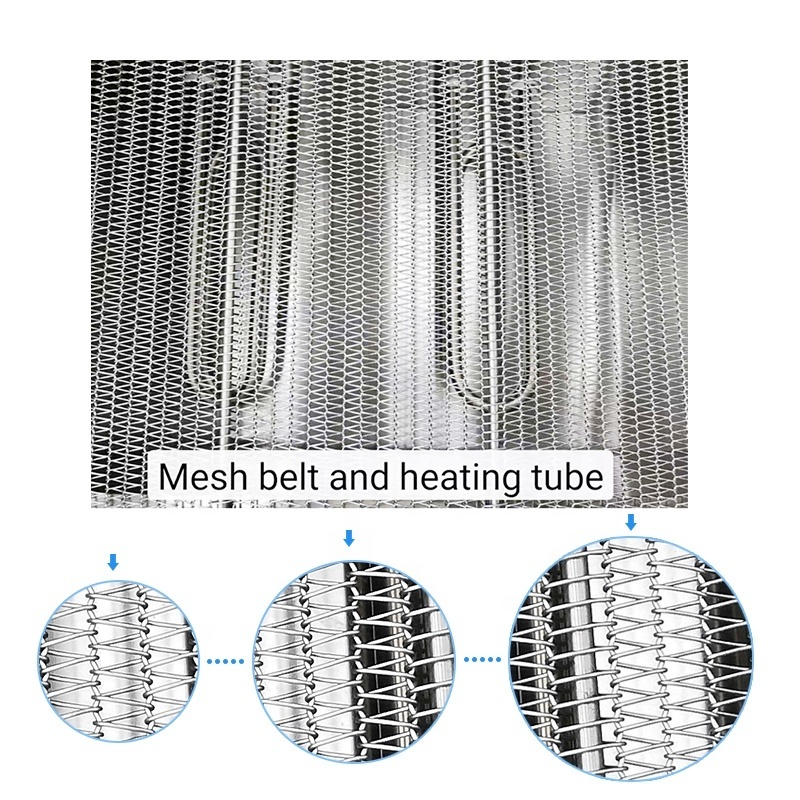

5. Steaming

The noodles are steamed through a continuous steamer. It is usually steamed at 100°C for 5 to 10 minutes. Here, the starch in the

noodles becomes digestible.

6. Cut off and inputs

The noodles are cut and shaped here. The length is generally 40 to 70 cm.

7. Frying

Fry the noodles together with the metal frame in edible oil at 150-170°C for 1 to 2 minutes. In the dough stage, the water content

of 30-40% becomes 3 to 6%, and the starch is further gelatinized.

8. Cooling

Blow the noodles with cold air to cool. After that, check the weight, shape, color, dryness, fried state, cooling temperature,

etc.

Compound Roller Machine

Boiling machine

Fryer machine

|

Application

|

Instant noodle production line

|

|

Motor

|

Siemens

|

|

Inverter

|

Delta, ABB, LG, FUJI,OMRON,customizable

|

|

Dimension(L*W*H)

|

21*2.8*3.0m

|

Instant Noodles Instant noodles are made from wheat flour, starch, water, salt or kan sui (an alkaline salt mixtureof sodium carbonate, potassium carbonate, and sodium phosphate), and other ingredients that improve the texture and flavor of noodles.