- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xing Tai Long

-

Color:

-

Pure White,Pink,SlightYellowish Etc.

-

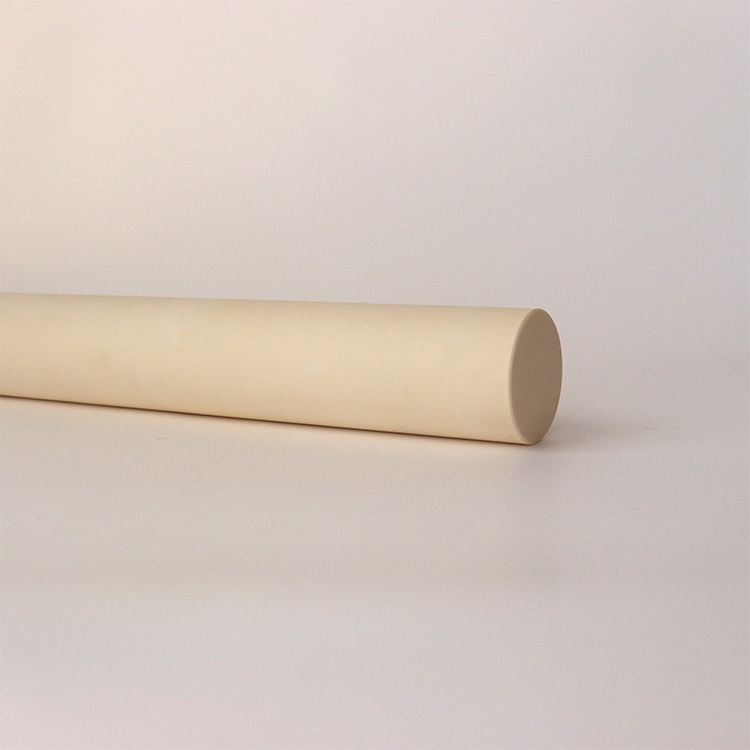

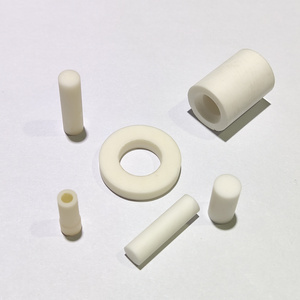

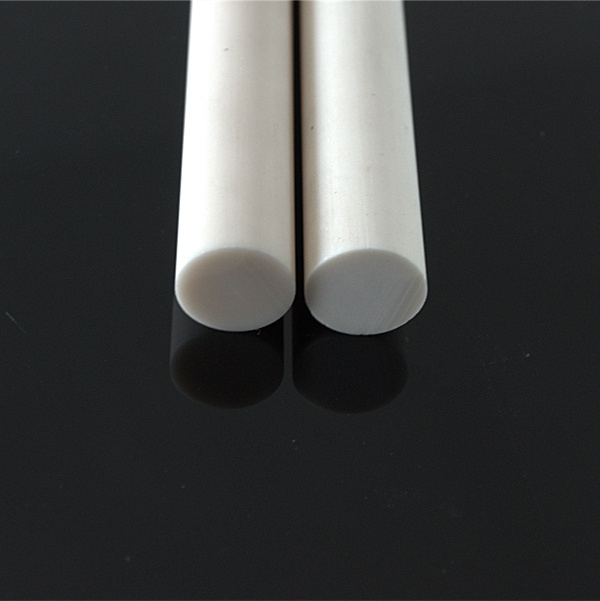

Name:

-

ceramic rod

-

surface smooth:

-

polish

-

Density:

-

3.9 ~ 3.92 g/cm3

-

Shape:

-

Solid,Round,Square Etc.And Customized Designs

-

Tolerance:

-

Polished Surface & Strict Size Tolerance To Be Min.0.05mm Tolerance

-

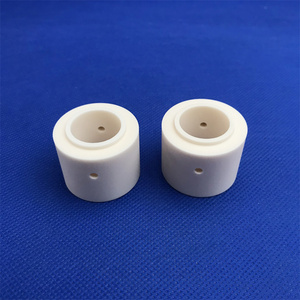

Bores:

-

1-4 Bores Or Made As Customized

-

Certification:

-

ISO9001-2008/CE

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

XTL

-

Brand Name:

-

Xing Tai Long

-

Color:

-

Pure White,Pink,SlightYellowish Etc.

-

Name:

-

ceramic rod

-

surface smooth:

-

polish

-

Density:

-

3.9 ~ 3.92 g/cm3

-

Shape:

-

Solid,Round,Square Etc.And Customized Designs

-

Tolerance:

-

Polished Surface & Strict Size Tolerance To Be Min.0.05mm Tolerance

-

Bores:

-

1-4 Bores Or Made As Customized

-

Certification:

-

ISO9001-2008/CE

95% 99% alumina ceramic rod

About this item

- Common application are: kiln/furnace components, spacers, bushings, insulators, nozzles, sleeves, seal rings, support pins & wear resistant components.

- Readily available material with reasonable cost possessing excellent properties handling thermal and mechanical shock.

- Can be fabricated and used in a wide range of applications from stock to tight tolerance machined parts.

- Safe operating temperature up to 2500ºF

Alumina rod

is made of

aluminum oxide (Al2O3) ceramic

– a fine ceramic material that is widely used in various industries.

Aluminum oxide rod

has superb performance in electrical insulation, high chemical resistance, and low thermal expansion.

Alumina rod

is made of

aluminum oxide (Al2O3) ceramic

– a fine ceramic material that is widely used in various industries.

Aluminum oxide rod

has superb performance in electrical insulation, high chemical resistance, and low thermal expansion.

XTL offers tailor-made alumina ceramic rods in a wide range of purities, 95%, 96%, 99%, 99.5%, 99.8%. The surface finish of alumina ceramic rods can be as fired, fine grinding or polishing, the geometry can be machined into tight tolerance to meet high fitting requirements. Besides, thread can be machined on the both ends of alumina ceramic rods for fastening purpose. No matter small quantity for prototype or big quantity for batch production, we are always ready to provide our service.

Performance For Industrial Ceramic

|

Composition |

UNIT |

AL97 |

AL98 |

|

AL2O3 Purity |

% |

97 |

99.8 |

|

Color |

N/A |

White |

Ivory |

|

Tensile |

Kpsi |

30 |

32 |

|

Flexural |

Kpsi |

55 |

60 |

|

Compressive |

Kpsi |

300 |

330 |

|

Density |

g/cc |

3.70 |

3.92 |

|

Hardness |

HV, GPa |

13.8 |

18 |

|

Thermal Conductivity |

W/ (m K) |

25 |

32 |

|

C.O.T.E. |

In / In°C (x107) |

77 |

78 |

|

Working temperature |

°C |

1500 |

1750 |

|

Dielectric Constant |

N/A |

9.5 |

9.8 |

|

Volume Resistivity |

Ohm-cm |

>10 14 |

>10 15 |

|

Dielectric Strength |

KV/mm |

16 |

20 |

Main properties of alumina ceramic rod

-

Good strength and stiffness

-

Extremely high hardness (Moh's hardness 9)

-

Exceptional wear resistance

-

Good corrosion resistance to acid and alkali

-

High temperature resistance up to 1750℃

-

Excellent electrical insulation

-

Low dielectric constant and dielectric loss

Typical applications of alumina ceamic

-

Mechanical seal rings

-

Pump plungers or pistons

-

Electronic substrates

-

Ceramic crucibles

-

Textile eyelets or guides

-

Ceramic balls/valves/seats for valves

-

Electrical insulators

-

Wear resistant nozzles

-

Ceramic furnace tubes

-

Ceramic thermocouple protection tubes

Machining Ability of Alumina Ceramics

Dimensional accuracy: Up to 0.001mm

Surface roughness: Ra0.05-3.2μm

Concentricity: Up to 0.02mm

Parallelism: Up to 0.01mm

Accuracy of Inner hole Drilling: Up to 0.01mm

Cylindricity: Up to 0.02mm

Thread machining: Minimum internal thread M2

Surface finish: As fired, glazed, grinding, polishing, metallization

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.