- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/110V

-

Power:

-

50HZ

-

Dimension(L*W*H):

-

2*2.5*2

-

Weight:

-

4380 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

small pulp tray machine

-

Raw material:

-

Waste paper/Carton

-

Finished Products:

-

Paper Tray

-

Machine type:

-

Reciprocating type

-

Water consumption:

-

0.15t/h

-

Waste paper consumption:

-

0.053t/h

-

Worker requirement:

-

3-4workers

-

Production:

-

700pcs

-

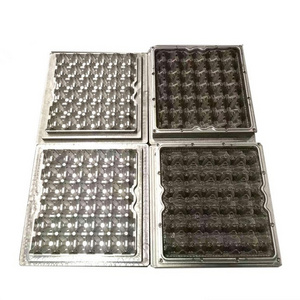

Egg tray mold quantity:

-

2 molds

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Wanyou

-

Voltage:

-

220V/110V

-

Power:

-

50HZ

-

Dimension(L*W*H):

-

2*2.5*2

-

Weight:

-

4380 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

small pulp tray machine

-

Raw material:

-

Waste paper/Carton

-

Finished Products:

-

Paper Tray

-

Machine type:

-

Reciprocating type

-

Water consumption:

-

0.15t/h

-

Waste paper consumption:

-

0.053t/h

-

Worker requirement:

-

3-4workers

-

Production:

-

700pcs

-

Egg tray mold quantity:

-

2 molds

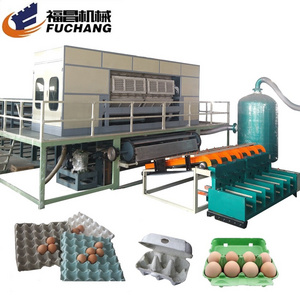

Wanyou High quality low cost small waste paper pulp egg tray machine

This type semi-automic production line wasn't equipped with drying system, after pulp making process and automatic forming process, the wet prodcuts should be moved to another place for drying by workers, and then prodcut can be dried by sunshine.

The above mentioned production line are suitable for all kinds of paper pulp molded product.

Parameters of small pulp tray machine:

|

1. |

Egg tray mould quantity |

2pcs |

|

2. |

Raw material |

Waste paper |

|

3. |

Output for egg tray |

700pcs/hour |

|

4. |

Net weight per piece (gram) |

70g-75g |

|

5. |

The volume of waste paper consumed |

0.06ton / hour |

|

6. |

The volume of water consumed |

|

|

7. |

Operators number |

3-4workers |

|

8. |

Area of workshop |

More than 240M ² |

|

9. |

Capacity of power |

40KW |

Advantage:

1.capacity 350/700/1000/1300/2000/3000/4000/5000/6000pcs per hour

2.wast paper as r aw materials

3.machine including making pulp unit ,moluding unit and dryer unit

4.computer control

The production line is mainly combined by THREE PARTS:

1. Pulping system

♦Put the waste paper into the hydraulic pulper. After about 40 minutes’ high consistency mixing, the waste paper will be made into rough pulp. The proportion is 1(paper) :3(water).

♦Then the rough pulp will flow into the homogenization pool. The rough pulp will be refined further by the pulp beater in the homogenization pool.

♦The appropriate concentration of the pulp will flow into the finished pulp to supply paper pulp to the forming machine.

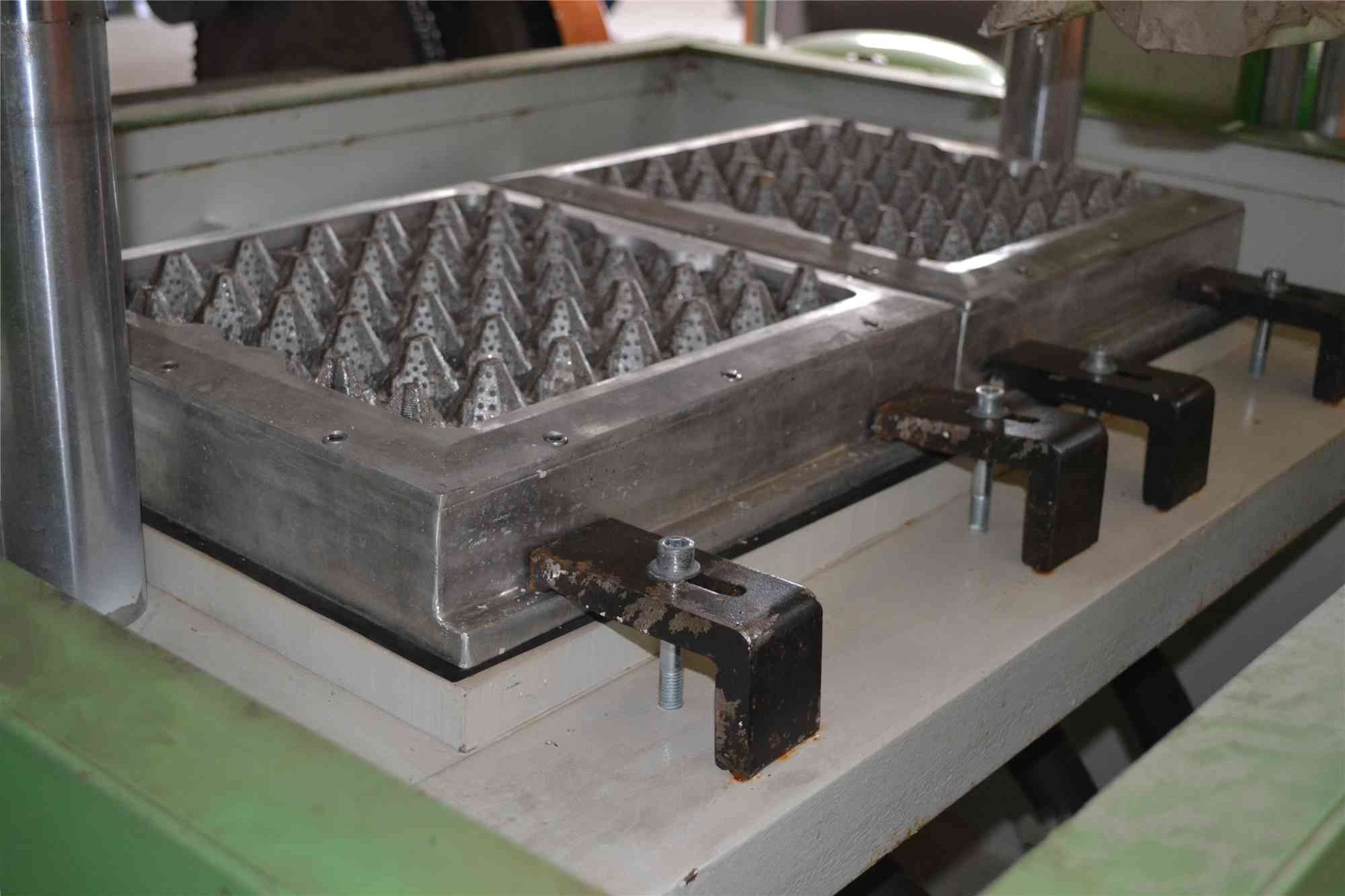

2. Forming system

♦By pulp pump, the finished pulp will be transported into the paper tray forming machine.

♦Under the suction power of vacuum pump, the pump will be adsorbed up on molds to form egg tray.

♦Under the blowing force of air compressor, the formed egg tray will drop off from molds.

3. Drying system

(Meaning : The formed Egg tray plate being delivered to Dryer, and come up to Completed Strong Egg tray plate) .

About the drying,you have 3 methods,by nature,by brick kiln and by metal dryer.

Samples by small pulp tray machine :

By container: