- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LM

-

Voltage:

-

380V /50Hz/3PH

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

6420mm*1020mm*1380mm

-

Weight:

-

3270 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Name:

-

Purlin Roll Forming Machine

-

Raw material:

-

Color steel sheet or galvanized steel shee

-

Usage:

-

Building

-

Color:

-

Customers Requirement

-

PLC:

-

Siemens brand (ABB brand is available if required)

-

Cutting blade material:

-

Cr12, heat treatment

-

Roller material:

-

GCr15, CNC lathes, Hard Chrome Coated

-

Product name:

-

High Quality Galvanized Steel Sheet U Purlin Roll Forming Machine

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United Kingdom, United States, France, Germany, Viet Nam, Saudi Arabia, Indonesia, Pakistan, India, Russia, Spain, Thailand, Australia, Morocco, Kenya, Argentina, South Korea, UAE, Colombia, Algeria, Romania, South Africa, Kazakhstan, Kyrgyzstan, Tajikistan

-

Certification:

-

CE, SONCAP etc.

Quick Details

-

Work Pressure:

-

16Mpa

-

Production Capacity:

-

Custom

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LM

-

Voltage:

-

380V /50Hz/3PH

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

6420mm*1020mm*1380mm

-

Weight:

-

3270 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Name:

-

Purlin Roll Forming Machine

-

Raw material:

-

Color steel sheet or galvanized steel shee

-

Usage:

-

Building

-

Color:

-

Customers Requirement

-

PLC:

-

Siemens brand (ABB brand is available if required)

-

Cutting blade material:

-

Cr12, heat treatment

-

Roller material:

-

GCr15, CNC lathes, Hard Chrome Coated

-

Product name:

-

High Quality Galvanized Steel Sheet U Purlin Roll Forming Machine

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United Kingdom, United States, France, Germany, Viet Nam, Saudi Arabia, Indonesia, Pakistan, India, Russia, Spain, Thailand, Australia, Morocco, Kenya, Argentina, South Korea, UAE, Colombia, Algeria, Romania, South Africa, Kazakhstan, Kyrgyzstan, Tajikistan

-

Certification:

-

CE, SONCAP etc.

|

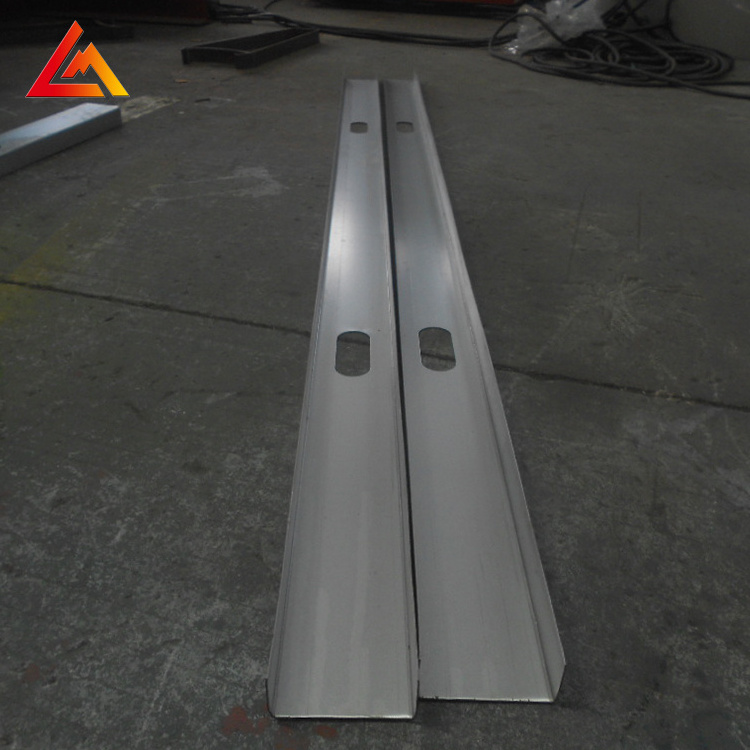

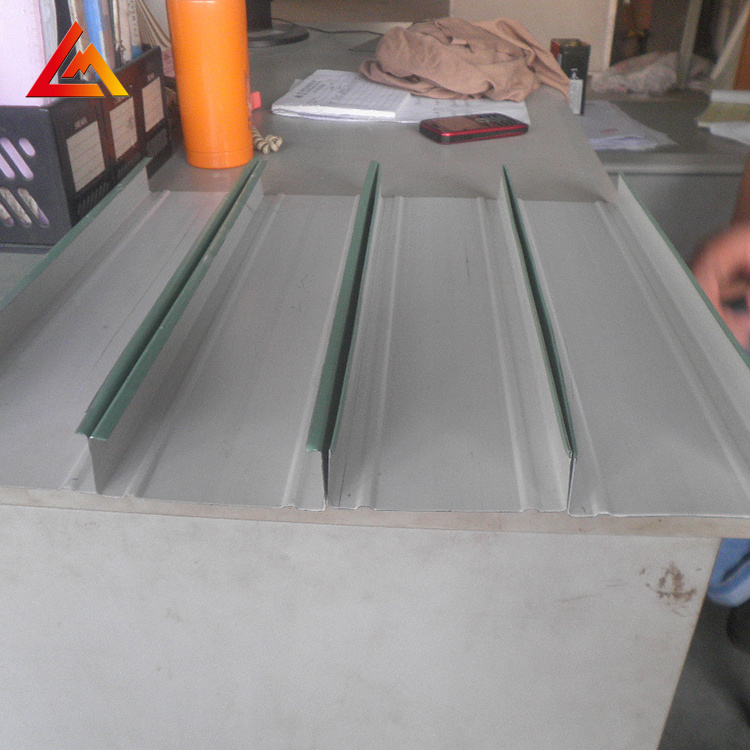

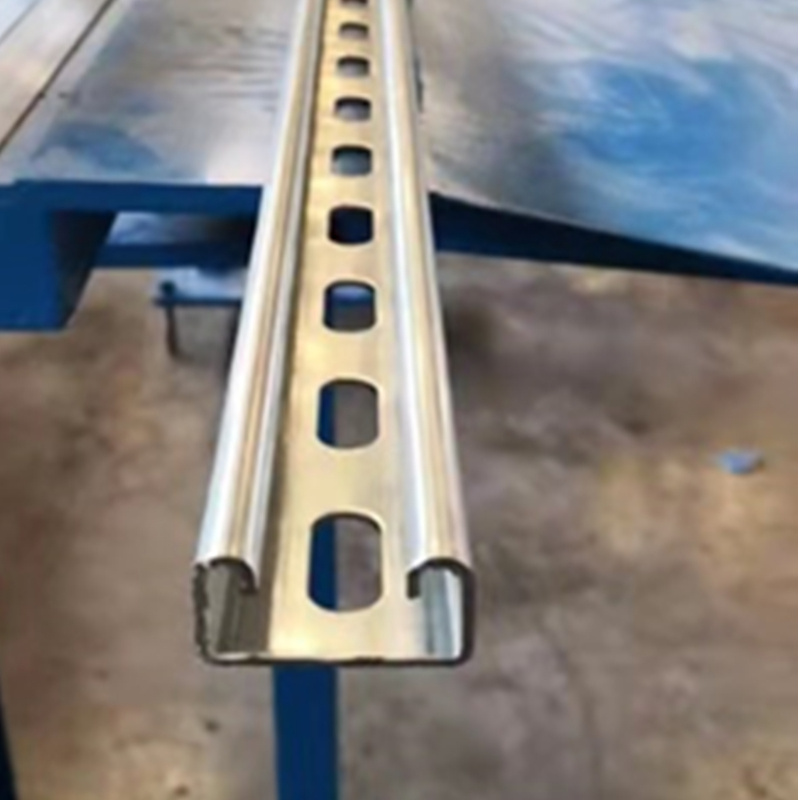

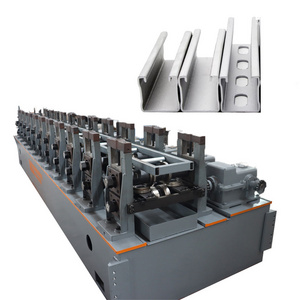

Type |

Roll former for U PURLINE |

|

S hearing Thickness |

Up to Max. 0.8mm |

|

T hickness |

1.0 mm-1.5 mm |

|

Frame Design |

Wall-plate-frame-design / New-stand-frame-design |

|

Roll S tages |

10 stages |

|

Material Of Forming Roller |

GCr15, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ 75 mm |

|

Main Motor Power |

7.5 KW |

|

Max. Line Speed of Roll Former |

12-14 m/min (Higher speed is available, depends on the specification required by the buyer) |

|

Hydraulic Group Power |

4 KW |

|

Material of Cutting Blade |

Cr12 , hear treatment |

|

Electric Standard |

380V / 50H z/3PH or as per customer's requirements |

|

Machine Dimensions |

6420 mm × 1020mm × 1380mm ( estimated only) |

|

Major Color of Machine Painted |

RAL 5015 (Blue) or as per customer ’ s requirements |

Service After Sell:

In correct operation & maintaining, the machine is guaranteed for one year since leaving. our factory exclud ing the electric elements.

Installation:

(1) If installation is needed, Liming ( the seller ) will dispatch technician to the buyer’s factory abroad to assist regulating the machine with charge free. The buyer should assist Liming to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation.

(2) If installation is needed, the buyer shall make the following preparation before arrival of technicians.

a) Position the machine in the buyer’s factory.

b) Prepare necessary electric wiring.

c) Prepare material of trial running.

d) Provide labors for assistance and installation during installation.

e) If possible, One Chinese-speaking interpreter so that the communication between the buyer and seller’s technician will go smoothly .