- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Good super resin

-

Model Number:

-

HN-116(2)

-

Type:

-

solvenb based pu adhesive glue

-

Application Method:

-

scrap coat by machine

-

shelf life:

-

12 months

-

Keywords:

-

panel lamination glue

-

Application:

-

lamination PVC film to MDF or Wood

-

Viscosity:

-

6000-8000CPS

-

Solid content:

-

31-33%

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

PVC film laminating adhesive

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Good super resin

-

Model Number:

-

HN-116(2)

-

Type:

-

solvenb based pu adhesive glue

-

Application Method:

-

scrap coat by machine

-

shelf life:

-

12 months

-

Keywords:

-

panel lamination glue

-

Application:

-

lamination PVC film to MDF or Wood

-

Viscosity:

-

6000-8000CPS

-

Solid content:

-

31-33%

MDF and wood lamination adhesive glue

Item: HN-116(2)

PU adhesive for profile wrapping PVC film to MDF

Description: HN-116(2) is a kind of double-component adhesive glue especially developed for laminating wooden board or mdf. It has strong intial bonding strength and ultimate peel strength. Moreover, It has good performance in heat resistance and anti-heat-shrinkage.

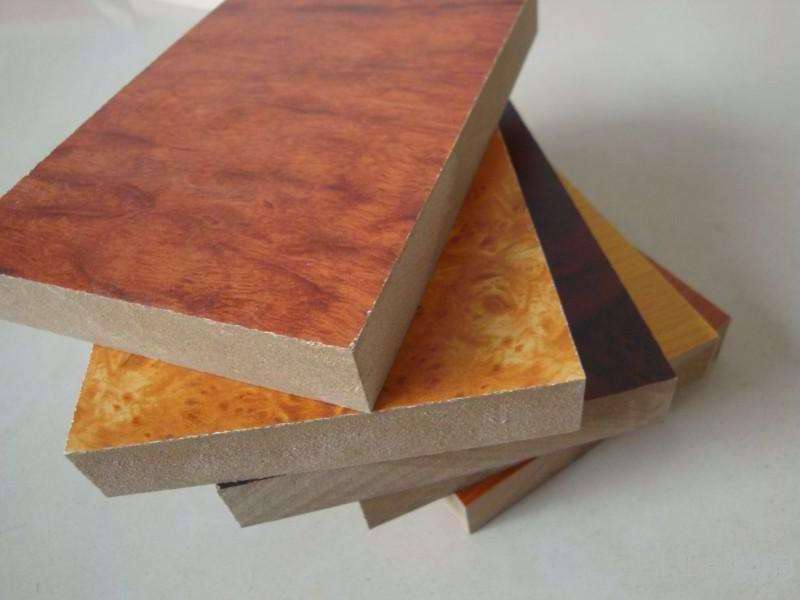

Application: The adhesive glue is used to wrap or laminate PVC film to wooden profile or wooden board, density board, mdf, etc.It is very good for lamination wall panels,baseboards.

Typical application:

- For PVC film PVC paper to MDF,WPC

- For wooden profile

- For wooden door panel

- For wood-like floor

- For wooden flooring line

Working condition

- Machine: Profile wrapping/laminating machine, glue film coating machine

- Coating weight (glue spread): 30g~60g, or base it on the thickness and roughness of the film, application with roller coater or slot coater

Working temperature

- Preheating temperature for Aluminium profile or other metal: 50~7 0 °C

- Oven temperature: 60~8 0 °C

Wrapping or laminating speed: 8~12 m/min, or adjust it based on the types of material. Flatten the film by the roller after the glue dries.

Note:

- The adhesive must be mixed with the hardener(curing agent) HN-812 based on the ratio 100: 3, then agitate the mixture and get them fully mixed up.

- If the mixture is not fully mixed up or not follow the ratio to mix up, it will affect the adhesive performance on the final bonding strength and heat resistance.

- The adhesive mixture has good performance within 4 hours under normal termperature 25~3 0 °C , please use it up within the period and DO NOT pool it back to the adhesive.

- DO NOT mix this adhesive with other adhesive.

MOQ: 1 20' FCL

3kg/tin and 5376 tins per 20' FCL

15kg/tin and 1242 tins per 20' FCL