1. Cleaning is totally automatic

2. Precise temperature control

3. Suitable for different thermo plastic polymers

4. Short cleaning cycles and low energy consumption

5. Safety and no pollution

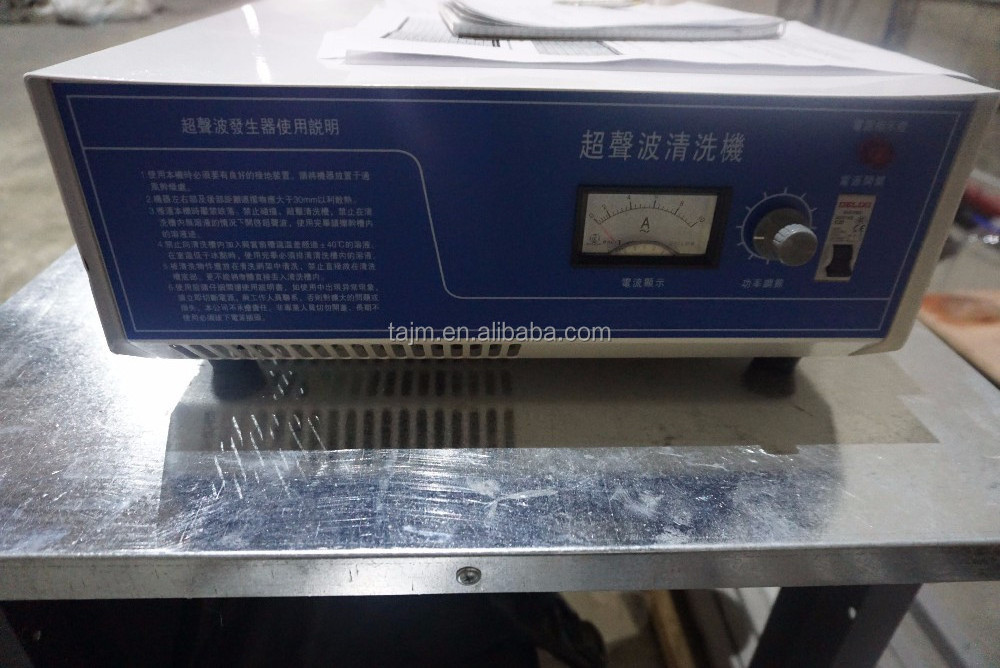

Ultrasonic Cleaning Machine 200L Pcb Injector Ultra Sonic Cleaner

1. Cleaning is totally automatic

2. Precise temperature control

3. Suitable for different thermo plastic polymers

4. Short cleaning cycles and low energy consumption

5. Safety and no pollution

Parameter

1 Input power supply AC220V 50Hz

2 Output power 1500W

3 Operating frequency 28KHz

4 operating current 3.5A

5 Size of cleaning cylinder L550*W550*H200

6 Volume 60L

7 Outside measurement

8 Quantity of transducers 24pc

Ultrasonic propagated in liquid can clean dirt on the surface of an object, the theory thereof can be explained by the phenomenon of “cavitation”: when sound wave pressure propagated by ultrasonic vibration in liquid reaches an atmosphere, the power density is 0.35 w/cm2, then the sound wave pressure peak value of ultrasonic can reach vacuum or negative pressure; however, no negative pressure actually exists, therefore, a tremendous force is produced in liquid and rip liquid molecules into a cavity, namely, a cavitation nucleus. The cavity is very close to vacuum, which can burst when the reversal of the ultrasonic pressure come up to the maximum. Intense impact produced from the burst can strike off dirt on the surface of an object. This phenomenon of generating a shock wave owing to burst of countless tiny cavitation bubbles is called “cavitation”. The cleaning machine adopts a single screw core type piezoelectric transducer which is bonded on a cleaning vibrating plate with high-strength structural adhesives, so that electric energy is transformed into ultrasonic mechanical energy.

Ultrasonic Cleaning Machine 200L Pcb Injector Ultra Sonic Cleaner