- Product Details

- {{item.text}}

Quick Details

-

Max. Turned Length (mm):

-

1500 mm

-

Brand Name:

-

CATEK CNC

-

Voltage:

-

380V/220V 50/60Hz

-

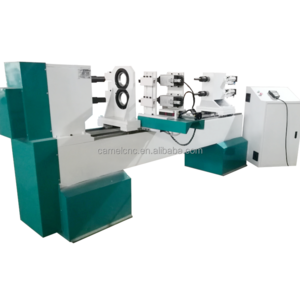

Dimension(L*W*H):

-

3400*2250*1700mm

-

Weight (KG):

-

1800

-

Power (kW):

-

4 - 11

Quick Details

-

Max. Swing Diameter (mm):

-

300 mm

-

Max. Length of Workpiece (mm):

-

1500 mm

-

Place of Origin:

-

Shandong, China

-

Max. Turned Length (mm):

-

1500 mm

-

Brand Name:

-

CATEK CNC

-

Voltage:

-

380V/220V 50/60Hz

-

Dimension(L*W*H):

-

3400*2250*1700mm

-

Weight (KG):

-

1800

-

Power (kW):

-

4 - 11

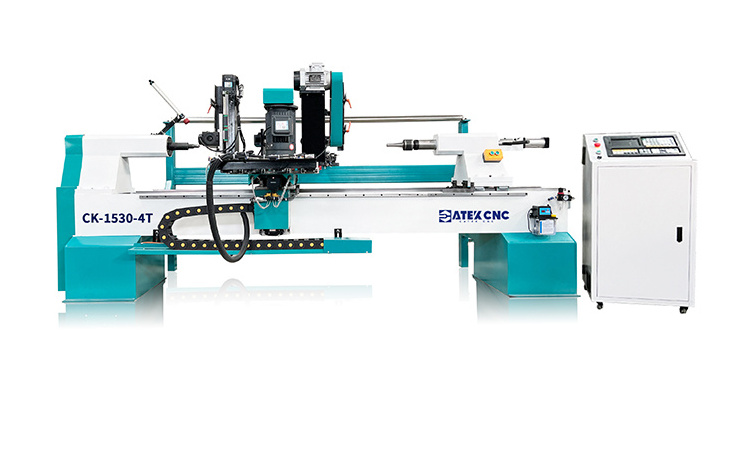

Products Description

Product Paramenters

|

Processing Size

|

1500mm length*300mm diameter

|

|

Bed Frame

|

Heavy-duty integral fully cast lathe, independent control cabinet

|

|

Motor

|

4KW servo rotating motor

|

|

Drive Mode

|

DORNA servo driver

|

|

Frequency Converter/ Inverter

|

BEST inverter/servo inverter

|

|

Spindle Speed Speed of Spindle

|

0-6000r/m

|

|

Transfer method Transmission way

|

The XY axis is driven by 25TBI ball screw, and the Z axis uses a high-precision helical rack or 32 screw

|

|

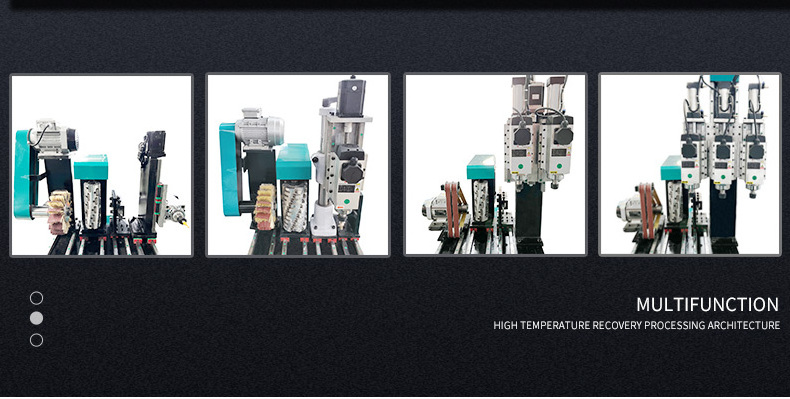

Milling Spindle

|

3.5kw high-speed air-cooled spindle(Support four-axis four linkage)

|

|

Milling Spindle Speed

|

0-18000r/min

|

|

Planer Knife

|

Length 240mm, diameter 90mm, 30 big blade

|

|

Grinding Wheel

|

independent motor control,230 mm diameter

|

|

Guide X,Y,Z Guide Rail

|

Taiwan Hiwin High Precision 25 Straight Line Square Rail

|

|

Device cable

|

pure copper cable

|

|

Control System

|

CATEK CNC special control system panel, CK1000TC

|

|

Lubrication system

|

Oil filling and maintenance system

|

|

Operating Voltage

|

AC380V/220V 50/60Hz

|

|

Compatible software

|

Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc.

|

|

Engraving instructions

|

Standard G code, u00, mmg, plt

|

|

Loading and unloading device

|

Multi-linkage cylinder loading rack (simple and easy to use)

|

|

Security system

|

All photoelectric limits of XYZ three-axis

|

|

Repeatability X,Y,Z Traveling Positioning Accuracy

|

±0.02mm

|

|

Toolbox

|

Turning tools, wrenches, collets, handwheels, thimbles, chucks, oil bottles, oil-water separators, relays, photoelectric limits,

etc. |

Sample display

Recommend Products

Details Images

Multi functional integration of turning, milling, planing, carving, drilling and polishing.(supporting 4-axis linkage)

CNC dedicated system, capable of reading NC, DFX, TXT formats, standard G code format, easy to operate

Imported SHANG YIN HIWIN high-precision slider, guide rail, TBI ball screw

Using pulse hand wheel control for more convenient and precise operation

Machines are all using independent control system and with strong anti-interference ability

Multiple change fully automatic feeding rack, simple and easy to use

Our Advantages

4KW pure copper coil with servo high-speed rotating motor, supporting position mode and speed mode switching, capable of rotating angles with a maximum speed of 6000R/M, high accuracy and fast speed

Ordinary three-phase asynchronous motor with a maximum speed of 2880R/M, using gear to control the angle with slow speed and low accuracy

All adopt DORNA closed-loop servo motors with high torque, accurate positioning high accuracy and fast speed.

Using ordinary motors with low torque, slow speed, low accuracy and prone to errors

The whole lathe uses a heavy-duty integral fully cast bed body which is cast at high temperature. The bed body has higher toughness and more stable structure. Improve the effectiveness and efficiency of processed products.

Using ordinary square iron pipes to weld the bed body has the advantages of light weight, machining vibration, easy deformation, detachment from welding, poor product processing effect and low efficiency.

Using an intelligent CNC system with a 7-inch large screen and high visualization degree, controllable accuracy of 0.01MM, simple operation and single person can operate multiple machines, improving efficiency and saving labor.

Old style switch button control with no screen, complex operation and requiring cooperation from technical personnel, low automation level which is inability to fully automate processing, low efficiency, and waste of labor.

Hot Searches