- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

<1.5%

-

CrO Content (%):

-

none

-

SiC Content (%):

-

none

-

Place of Origin:

-

Henan, China

-

Model Number:

-

TT-FO-200

-

Brand Name:

-

TONTEN

-

Processing Service:

-

casting, coating

-

Name:

-

forsterite olivine price

-

Application:

-

lost foam casting coating, refractory materials, etc.

-

Color:

-

lite gray

-

Keyword 1:

-

forsterite stuffing cast

-

Keyword 2:

-

magnesium olivine sand

-

Keyword 3:

-

casting special coating

-

Melting point:

-

1890℃

-

Density:

-

3.22-33g/cm3

-

Mohs hardness:

-

6.5~7.0

-

MOQ:

-

1ton

Quick Details

-

SiO2 Content (%):

-

42.8%

-

Al2O3 Content (%):

-

<2%

-

MgO Content (%):

-

57.2%

-

CaO Content (%):

-

<1.5%

-

CrO Content (%):

-

none

-

SiC Content (%):

-

none

-

Place of Origin:

-

Henan, China

-

Model Number:

-

TT-FO-200

-

Brand Name:

-

TONTEN

-

Processing Service:

-

casting, coating

-

Name:

-

forsterite olivine price

-

Application:

-

lost foam casting coating, refractory materials, etc.

-

Color:

-

lite gray

-

Keyword 1:

-

forsterite stuffing cast

-

Keyword 2:

-

magnesium olivine sand

-

Keyword 3:

-

casting special coating

-

Melting point:

-

1890℃

-

Density:

-

3.22-33g/cm3

-

Mohs hardness:

-

6.5~7.0

-

MOQ:

-

1ton

Products Description

Magnesium Olivine High Manganese Steel Casting With Magnesium Olivine Sand

|

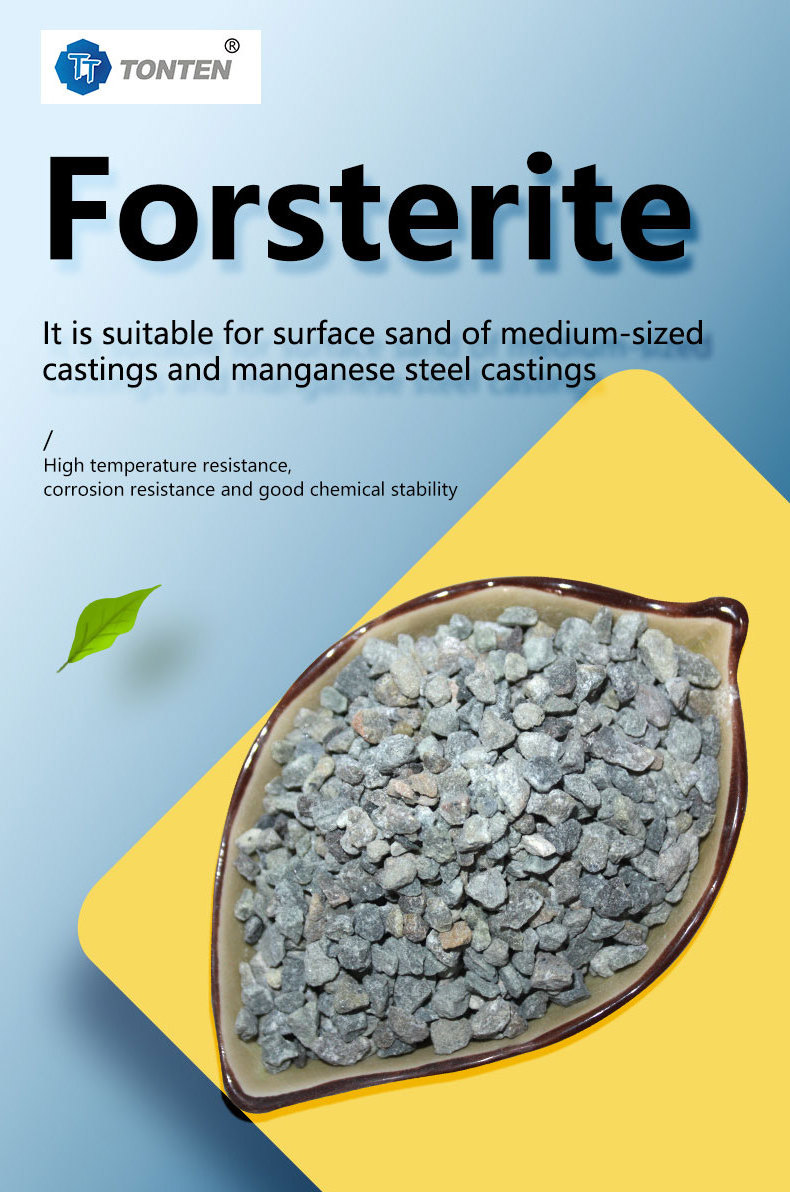

Forsterite Olivine

|

|

|

|

Appearance

|

Powder or sand or particles

|

|

|

Mohs Hardness

|

6.5-7

|

|

|

Density

|

3.22~33g/cm2

|

|

|

Melting Point

|

1890℃

|

|

|

MgO

|

>50%

|

|

|

Fe2O3

|

<6%

|

|

|

Al2O3

|

<2%

|

|

|

CaO

|

<1.5%

|

|

Forsterite olivine has high fire resistance (1710 ℃) and metal oxidation corrosion resistance, can prevent chemical sand sticking of castings, and ensure smooth casting surface and clear casting contour. The forsterite expands slowly at all temperatures, less than deformation, and has no characteristics of sudden expansion. The casting is not easy to produce main sand inclusion defects.

Good thermal conductivity

Good thermal conductivity, slow and uniform thermal expansion, not easy to produce sand inclusion.

Good production environment

No free SiO exists, no silica sand hazard, no CO gas is generated during casting, and the production environment is good.

High fire resistance

High fire resistance, strong resistance to metal oxide corrosion, can effectively prevent chemical and mechanical sand sticking of castings, good surface quality of castings, accurate size and high qualification rate.

High recovery

Due to the high melting point and stable chemical properties of magnesium olive sand, forsterite has strong etching ability for iron oxides and alkaline slag, is easy to recover, and can reduce the production cost.

Application Range

Magnesium Olivine High Manganese Steel Casting With Magnesium Olivine Sand

Forsterite is applicable to the production of medium, alloy steel and non-ferrous alloy

castings except carbon steel and low alloy similar to carbon steel

Product Photograph

Magnesium Olivine High Manganese Steel Casting With Magnesium Olivine Sand

Package & Shipping

Magnesium Olivine High Manganese Steel Casting With Magnesium Olivine Sand

The package and shipping info for forsterite price:

1. The forsterite can be packed in brown paper bag or plastic woven bag.

2. 25kg (55lb)/bag, 40 bags packed in a 1000kg (2200lb) bulk bag.

3. 25kg (55lb)/bag, 40 bags on a 1000kg (2200lb) pallet.

4. 1000kg (2200lb)/jumbo bag.

5. Customized packing available for forsterite olivine.

Factory Strength

Magnesium Olivine High Manganese Steel Casting With Magnesium Olivine Sand

Gongyi Tonten Abrasive Co.,Ltd major in the production and processing of Abrasives, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products, including Aluminium Oxide, Emery, Garnet, Copper Ore, Bauxite, Corundum, Carborundum, Fracturing Proppant, Ceramic sand, Water Clarifying Agent, and so on.

We always strive for our eight core enterprise cultures, which include Study, Innovation, Humanism, Integrity, Teamwork, Efficiency, Passion, Frugality. With a complete and scientific quality control system, our credibility, strength and quality are highly recognized by the whole industry. We sincerely hope to create a brilliant future with our worldwide friends.

FAQ

Magnesium Olivine High Manganese Steel Casting With Magnesium Olivine Sand

1. Who are we?

We are based in Henan, China, start from 2012, sell to Eastern Europe (25.00%), North America (20.00%), Eastern Asia (20.00%), Southeast Asia (15.00%), Western Europe (10.00%), South America (10.00%). There are total about 11-50 people in our plant.

2. How can we guarantee quality?

Always a pre-production sample before mass production. Always final Inspection before shipment.

3.What can you buy from us?

Abrasives, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products.

4. Why should you buy from us not from other suppliers?

We have more than 10 years experience in Abrasive industry and exported to many countries such as Korea, Japan and American markets. With a complete and scientific quality control system,we can supply customized processing according to customers requirements.

5. What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery.

Accepted Payment Currency: USD, EUR, CAD, AUD, HKD, CNY.

Accepted Payment Type: T/T, L/C, Money Gram, PayPal, Western Union, Cash.

Language Spoken: English, Chinese.

Hot Searches