- Product Details

- {{item.text}}

Quick Details

-

Power:

-

30-220kw

-

Weight:

-

6000 KG

-

After-sales Service Provided:

-

Engineers

-

Function:

-

Extruded Feed

-

Final product:

-

Dog Cat Chewing Teeth Treats

-

Advantage:

-

Easy Operation High Efficiency

-

Machine material:

-

Staineless Steel Food Grade

-

Motor:

-

Customuizd

-

Processing Types:

-

Twin Screw Extrusion

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

ARROW

-

Voltage:

-

380V/50HZ

-

Power:

-

30-220kw

-

Weight:

-

6000 KG

-

After-sales Service Provided:

-

Engineers

-

Function:

-

Extruded Feed

-

Final product:

-

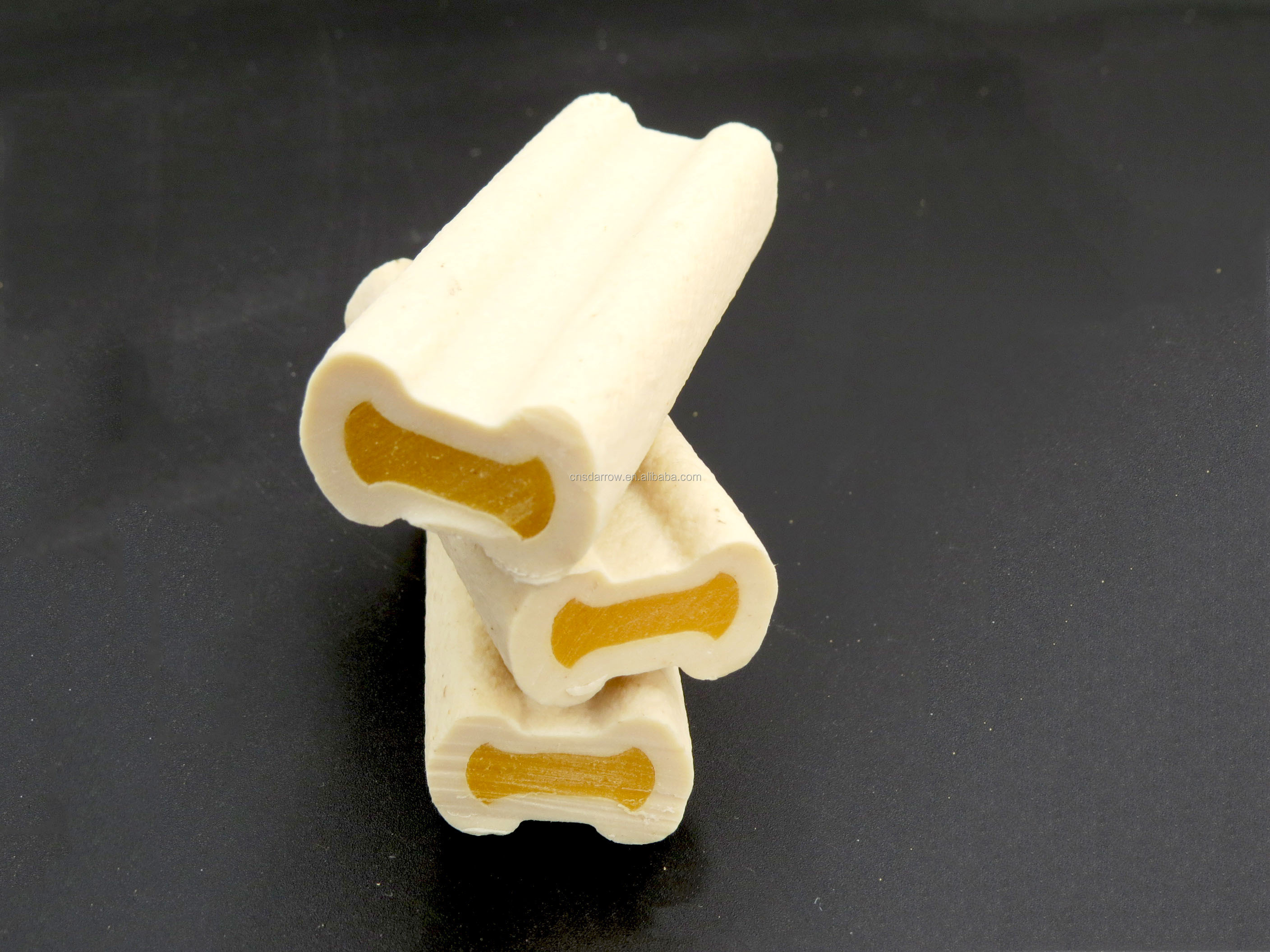

Dog Cat Chewing Teeth Treats

-

Advantage:

-

Easy Operation High Efficiency

-

Machine material:

-

Staineless Steel Food Grade

-

Motor:

-

Customuizd

-

Processing Types:

-

Twin Screw Extrusion

Products Description

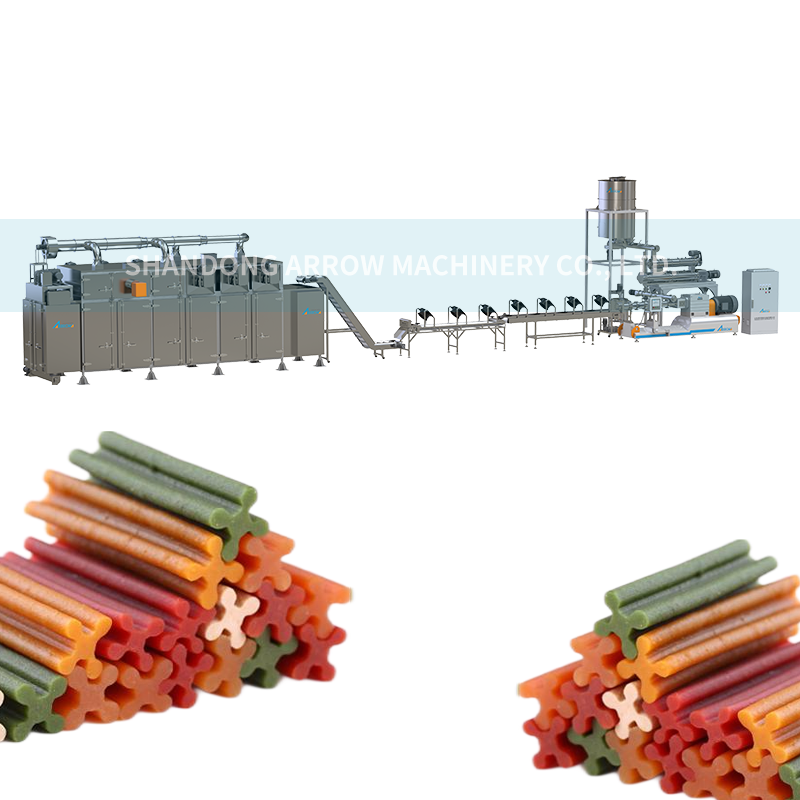

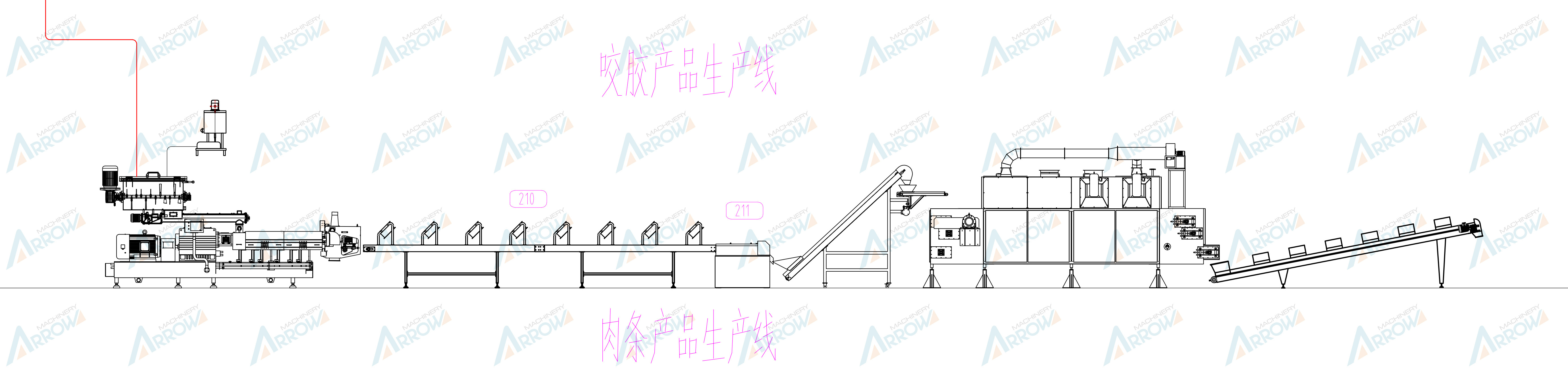

Arrow Pets Chews Production Line Machine Pet Dog Chew Food Making Equipment

Shandong Arrow Machinery Co,.Ltd.

cater to the emerging pet products market and the development of

pet chews equipment

-AYT-P05 model production line extruder, it can produce strips, bars, twisted bars, dual color, multi-color dog treats snacks. Our R & D center in the pet snacks manufacturing process continue to innovate, pay attention to the customer's recipe requirements, especially for the high content of fresh meat, viscosity products, choose the right production configuration, made products with better toughness, timeliness and plasticity.

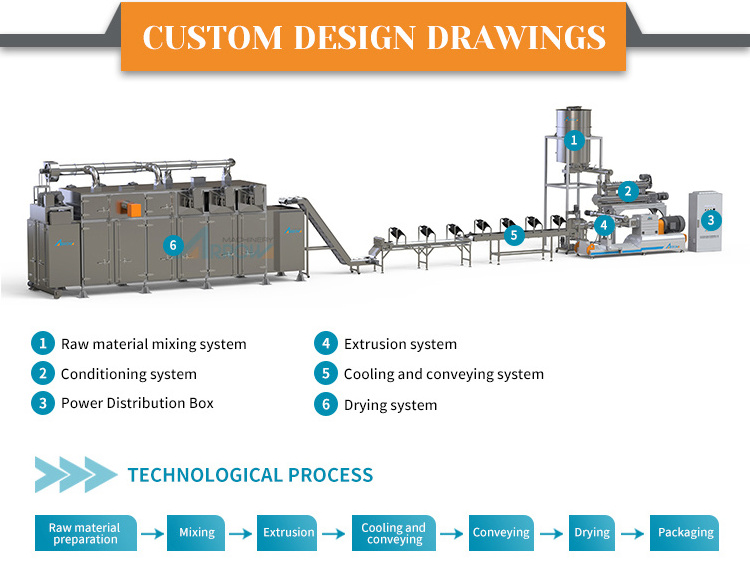

FLOW CHART

Blending→Conditioning→Extruding→(Twisting)→Cooling→Cutting→Drying→Packing

1)

Blending

:

With paste starch and fresh meat as the main raw materials, with edible gum, flavoring agent, animal fat and other raw materials, in the mixer to mix thoroughly, add to the feeder.

2)

Conditioning:

The conditioning mixes and heats raw materials, steam or other liquid.

3)

Extruding:

The material will through high pressure, high temperature in the barrel, and then be formed by mold at the outlet.

4)

Twisting:

When producing multi-color or special-shaped chews, it is necessary to add a special twisting machine to make the product reach the ideal state.

5)

Cooling:

The strip chews pass through one or more cooling conveyor belts to reduce the temperature of the product and shape it.

6)

Cutting:

The cutting machine cuts the product at a constant speed according to the set length.

7)

Drying:

The high-humidity chews are passed through a hot-air cross-circulation dryer to gradually dry the moisture without destroying the original flavor and extend the shelf life.

8)

Packing:

Packing gives protection to the chews food and also give easiness to handle and transport to customer's hand.

Sample & Application

Our machines are able to control the parameters precisely so that the product can be finished at the specified temperature, pressure, humidity and time. The rational design, the special materials, the stability and serviceability of the machine ensure that the various shapes and flavours of pet food are met without demand.

Products Show

|

NO

|

Model

|

Power (kw)

|

Capacity (kg/h)

|

|

1

|

AHT36-32D

|

18.5

|

5-30

|

|

2

|

AHT50-28D

|

37

|

60-100

|

|

3

|

AHT62-32D

|

90

|

200-350

|

|

4

|

AHT72-28D

|

110

|

350-500

|

Hot Searches