- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dingcheng

-

Product name:

-

Rail Rubber Pad

-

Processing:

-

Extruding

-

Feature:

-

Durable

-

Application:

-

Station platforms,Freight yards,Railroad

-

Rail fitting:

-

UIC54,UIC60, BS 80 lbs,BS 100 lbs

-

Operating Temperature:

-

-50~70 Degrees

-

Other name:

-

Rubber block for sleeper

-

Raw Material:

-

Rubber, EVA, HDPE, Elatomeric

-

Standard:

-

UIC, AREMA, TB/T2626-95

-

Sample:

-

Available

Quick Details

-

Material:

-

Rubber, EVA, HDPE, Elatomeric

-

Dimensions (L x W x H) (mm):

-

as per requirement

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingcheng

-

Product name:

-

Rail Rubber Pad

-

Processing:

-

Extruding

-

Feature:

-

Durable

-

Application:

-

Station platforms,Freight yards,Railroad

-

Rail fitting:

-

UIC54,UIC60, BS 80 lbs,BS 100 lbs

-

Operating Temperature:

-

-50~70 Degrees

-

Other name:

-

Rubber block for sleeper

-

Raw Material:

-

Rubber, EVA, HDPE, Elatomeric

-

Standard:

-

UIC, AREMA, TB/T2626-95

-

Sample:

-

Available

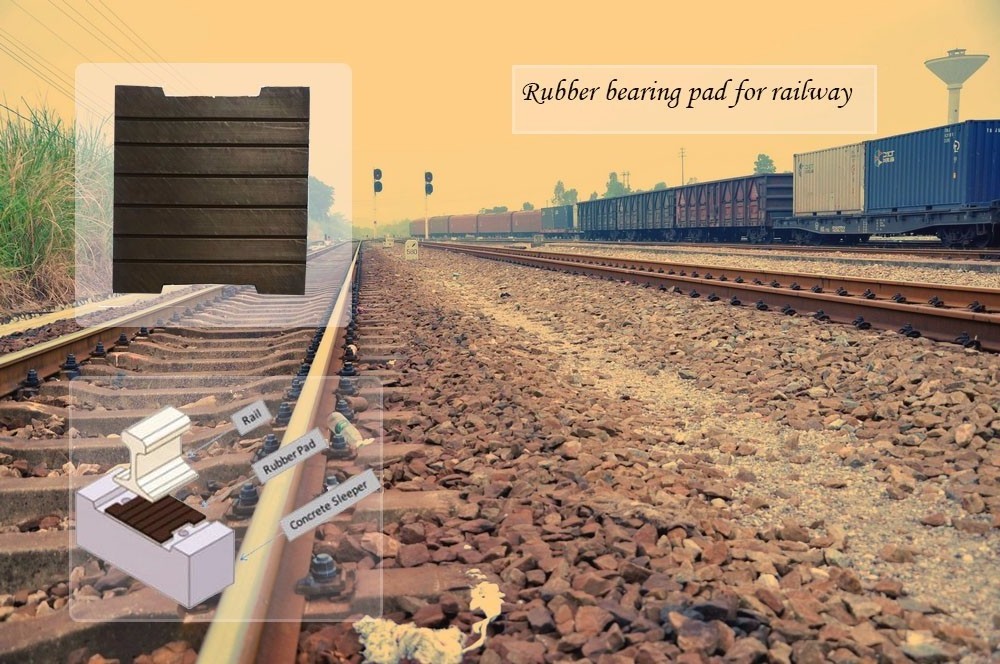

Rail Construction Elatomeric Rail Rubber Pad used under railway sleeper

Rail rubber pads for railway track structure are important components in the track structure. They are installed between steel rails and concrete sleepers. Its main function is to buffer the high-speed vibration and impact generated when vehicles pass through the rails, protect the roadbed and sleepers, and provide signal The system is electrically insulated, and the rubber pad is exposed to the atmosphere for a long time, so it is required to have good resistance to natural aging, cold and heat resistance.

|

Product name |

Rail rubber pads |

||

|

Application |

UIC 54,UIC 60, BS 80 lbs,BS 100 lbs |

||

|

Material |

HDPE |

EVA |

|

|

Technical Parameter |

density: 0.95-0.98g/cm 3 |

density: 0.95-0.98g/cm3 |

|

|

|

Tensile strength : ≥19Mpa |

Tensile strength:≥15Mpa |

|

|

|

Elongation: >80% |

Elongation: >500% |

|

|

|

Melting point: 170-190°C |

Melting point: 170-190°C |

|

|

|

Insulation resistance: ≥1×1010Ω |

Insulation resistance:≥1×1010Ω |

|

|

|

Hardness:≥98A |

Hardness: ≥90A |

|

|

Color |

Black |

||

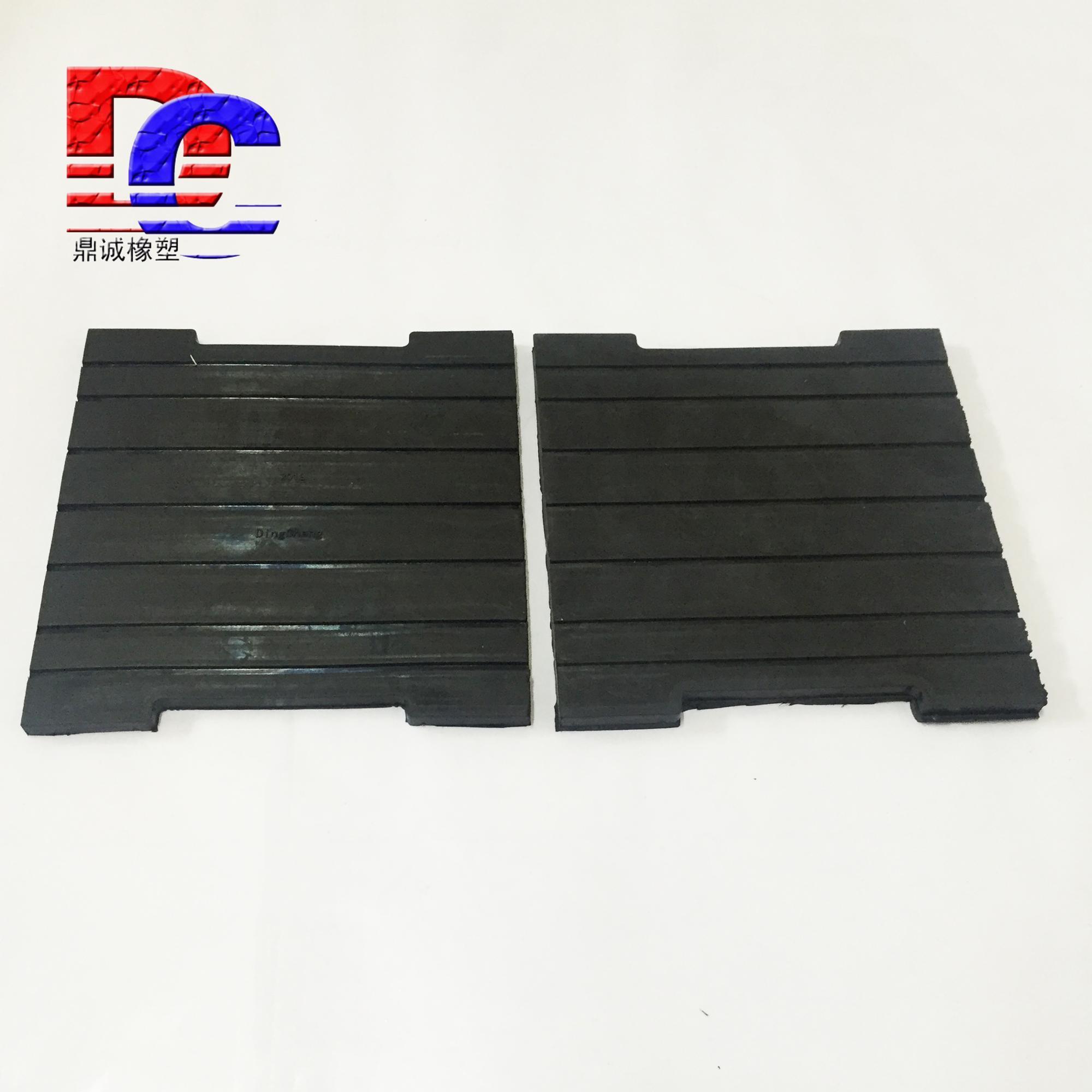

Characteristics of rail rubber pads under the rail

1.

Shock absorption, anti-aging, abrasion resistance, stability, high and low temperature resistance

, the products are natural rubber, styrene butadiene rubber, neoprene, HDPE, EVA, high density polyethylene and other combinations, product flexibility High, and not easy to deform or break under various temperatures.

2. Long service life,

low maintenance and replacement cost

.

3.

Complete models

, suitable for laying of various rails such as 43KG, 50KG, 60KG, wooden sleepers, concrete sleepers and other sleepers. With

strong force, shockproof performance, good insulation performance, wear resistance, less deformation after repeated compression, high strength, aging resistance, no mud turning, long service life, easy installation.

Using rail rubber pads can greatly improve the transportation capacity of motor vehicles, reduce the number of crossing maintenance, and avoid traffic accidents caused by motor vehicles stalling. The service life of the rubber backing board is more than 3 times longer than that of the original paving panel. Tests have confirmed that it can be stable without deformation when the applied pressure is over 80 tons.

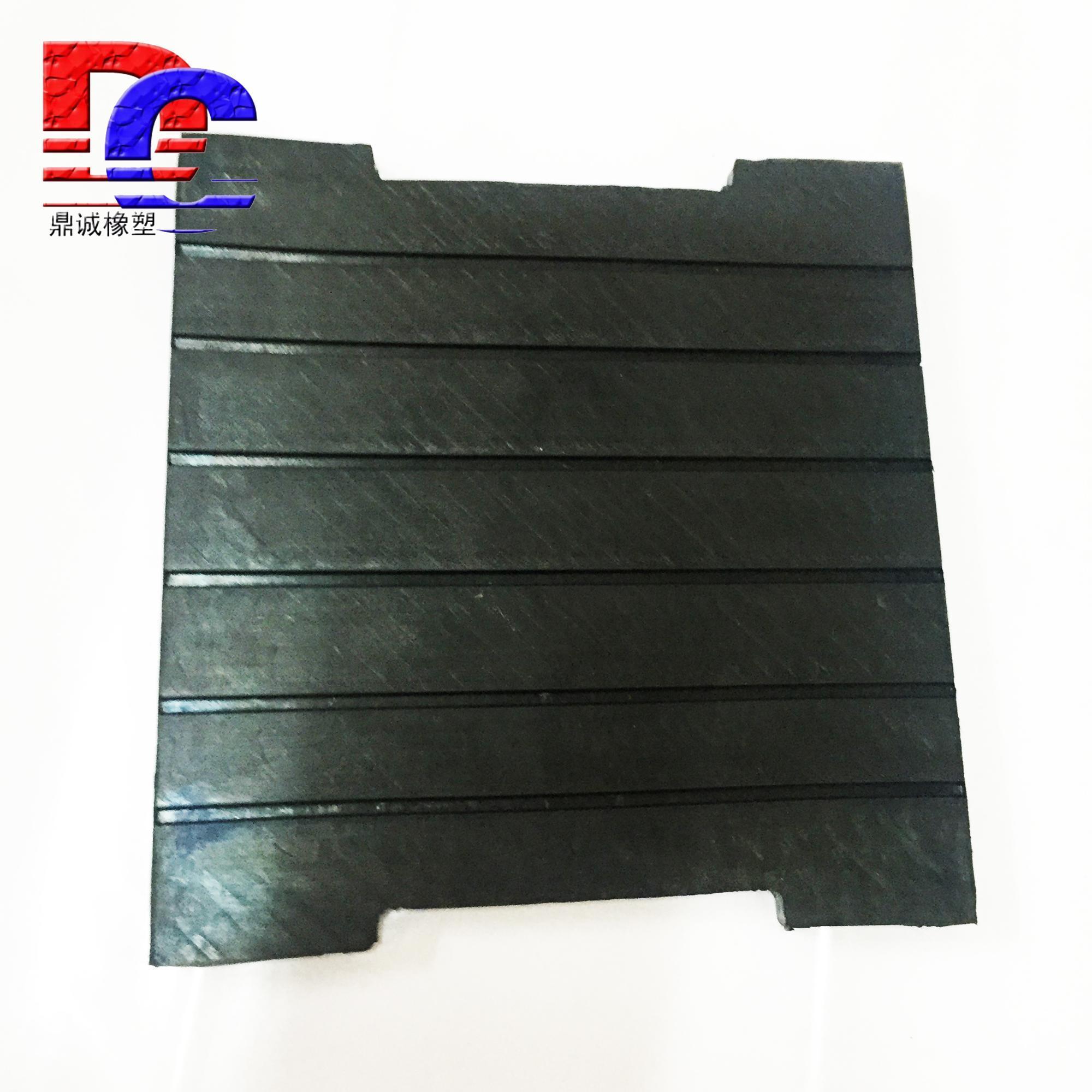

According to different uses, rail rubber pads are divided into two categories: insulated rail rubber pads and sleeper rail rubber pads.

Insulation rail rubber pads are divided into widened type and ordinary type according to their shape and width.

The rail rubber pads under the rail are divided into ordinary rail rubber pads, turnout rail rubber pads and rail rubber pads for urban subways according to the load of each meter of rail.

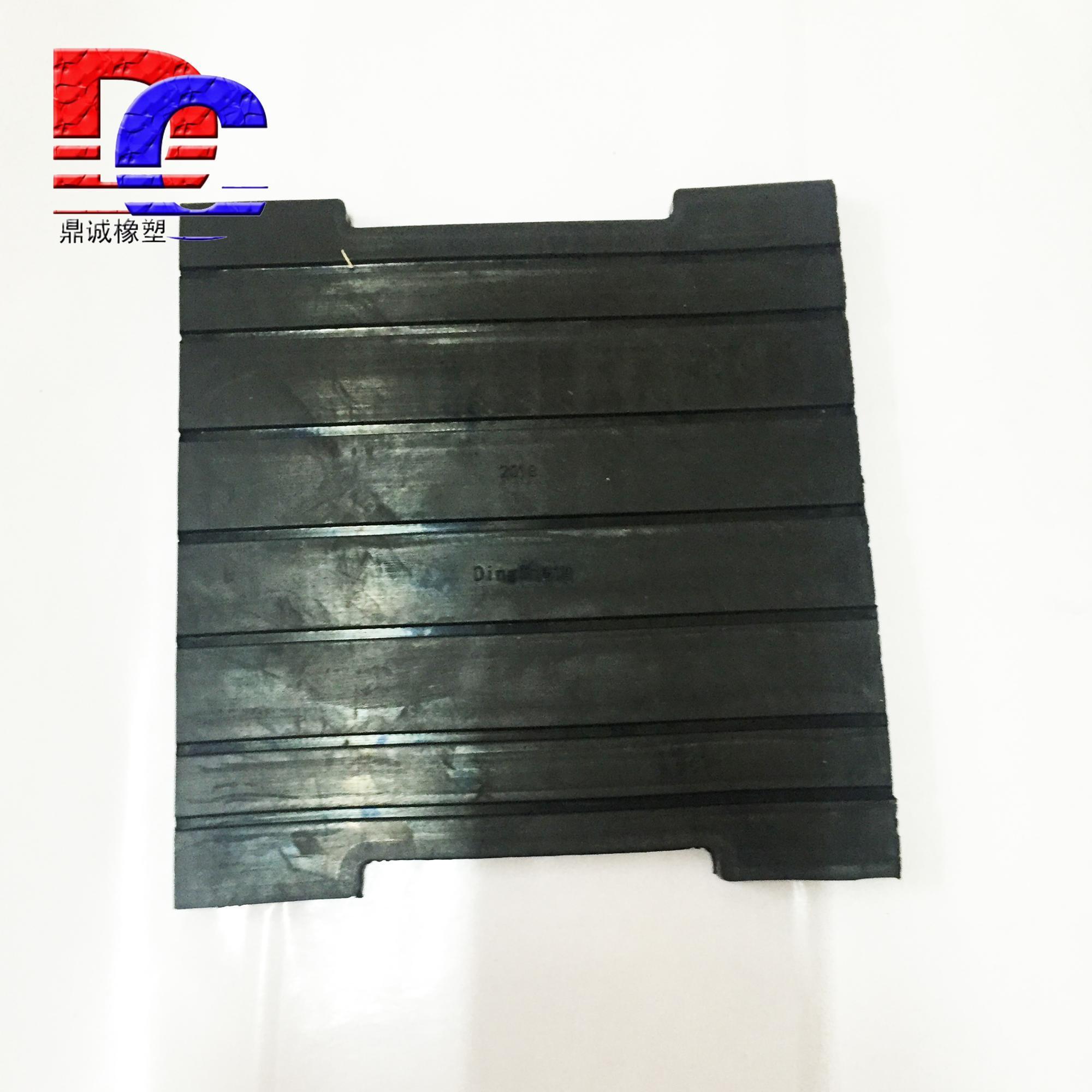

The appearance is medium hardness rail rubber with grooves or with cylindrical structure pads. Turnout sleepers are mainly used for sleepers at turnouts, slope-type rail rubber pads for bends, and oil-resistant rail rubber pads for stations.

Rail rubber pads for subway have good shock absorption and low noise performance.

Strict & advanced production

Rail rubber pads are made of rubber as the main raw material, scientific formula, and high-tech production technology.

Rail rubber pads meet the railway speed-up and environmental protection requirements, using it can improve the transportation capacity of locomotives.

The production and promotion of rail rubber pads has completely changed the old and backward paving materials such as asphalt, slate, steel plate and so on that have been used for a long time at railway level crossings. It has changed the backward state of uneven crossings, frequent accidents, and frequent maintenance. Laying, its environmental protection, quick installation and practicability, solid and solid safety are becoming more and more prominent.

It is pressure-resistant, abrasion-resistant, easy to install, and has firm contact with the road. The vehicle passes without impact and noise. It has good safety. Special rubber preparation and the Ministry of Railways Professional Design Institute jointly develop high-tech, advanced technology and testing methods.