- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

300 - 800 mm

-

Ejector Stroke(mm):

-

210 mm

-

Ejector Force(kN):

-

103 kN

-

Theoretical Shot Volume(cm³):

-

2608 cm³

-

Injection Rate (g/s):

-

817 g/s

-

Injection Weight (g):

-

2519 g

-

Screw Speed (rpm):

-

0 - 200 rpm

-

Screw diameter (mm):

-

90 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

860x800

-

Weight (KG):

-

20000 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

1010 mm

-

Model Number:

-

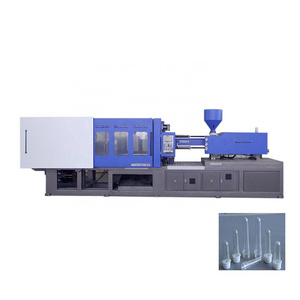

OUCO OC550H

-

Brand Name:

-

OUCO

-

Power (kW):

-

75 kW

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

860mm

-

Distance between Tie Bars(Height)(mm):

-

800mm

-

Plasticizing Capacity(g/s):

-

817

-

Mold Height(mm):

-

300 - 800 mm

-

Ejector Stroke(mm):

-

210 mm

-

Ejector Force(kN):

-

103 kN

-

Theoretical Shot Volume(cm³):

-

2608 cm³

-

Injection Rate (g/s):

-

817 g/s

-

Injection Weight (g):

-

2519 g

-

Screw Speed (rpm):

-

0 - 200 rpm

-

Screw diameter (mm):

-

90 mm

-

Screw L/D Ratio:

-

22

-

Distance between Tie Bars:

-

860x800

-

Weight (KG):

-

20000 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

1010 mm

-

Model Number:

-

OUCO OC550H

-

Brand Name:

-

OUCO

-

Power (kW):

-

75 kW

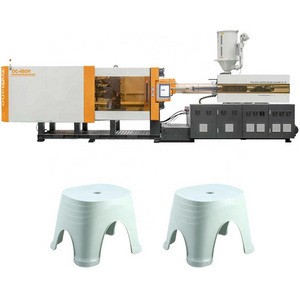

| Machine Model | 550T |

| Screw Model | C |

| Screw diameter | 90mm |

| Screw L/ D ratio | 22 |

| Theoretical injection capacity | 2608cm 3 |

| Shot weight ( PS) | 2519g |

| Opening stroke | 1100mm |

| Space between tie bar | 860x800mm |

| Min . mould height | 300mm |

| Max . mould height | 800mm |

| Machine dimensions(L × W × H) | 8.7mx2.1mx2.2m |

| Machine weight | 20t |

Jiangsu Ouco Heavy Industry Technology Group was founded in February 1984. The company is located at the foot of Ling Mountain, on the picturesque shores of Lake Taihu, in Yangshan Industrial Park, Huishan District, Wuxi City. In 2021, the group fully established Ouco (Wuxi) Injection Molding Machinery Co., Ltd. The company covers an area of 48,000m 2 , with a factory area of 35,000m 2 . The company is dedicated to the research and development of high-quality, high-performance injection equipment for markets such as medical equipment, large pipes, garbage bins, pallets, and fruit baskets. It provides customers with customized efficient, energy-saving, and professional production solutions. Committed and unwavering, pursuing perfection. Ouco is always committed to meeting customer needs and creating greater value for customers; this is the eternal philosophy of Ouco Injection. We will continue to lead in the market, fear no hardships or challenges, and strive to achieve energy-saving, automation, precision, and user-friendly aspects, providing customers with the greatest return on investment.

Ouco Injection molding machine owns a large gantry five-axis machining center. The production process is meticulous, with each step following scientific and rigorous standards and procedures, ensuring the precision and reliability of product assembly. We have introduced internationally advanced processing and testing equipment, implemented strict quality control and testing procedures, ensuring that every piece of equipment leaving the factory meets impeccable quality.

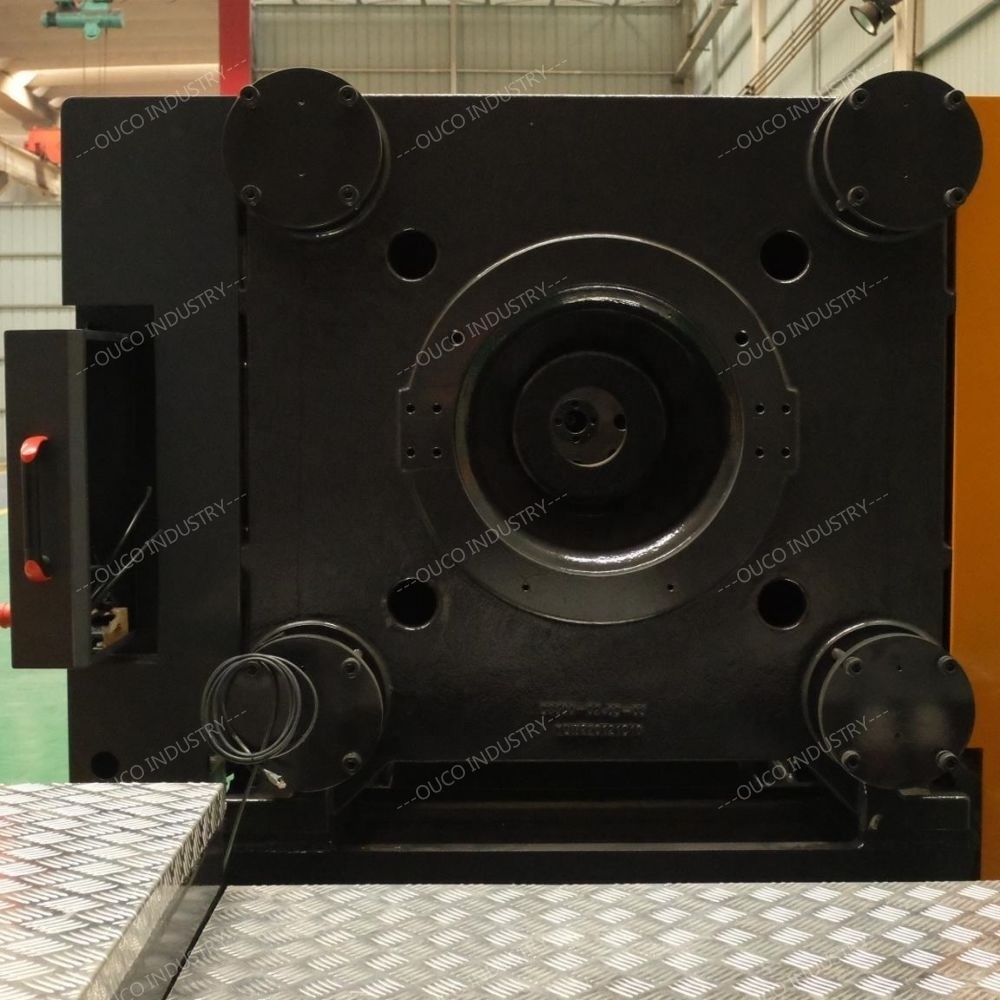

Extremely large capacity mold volume.

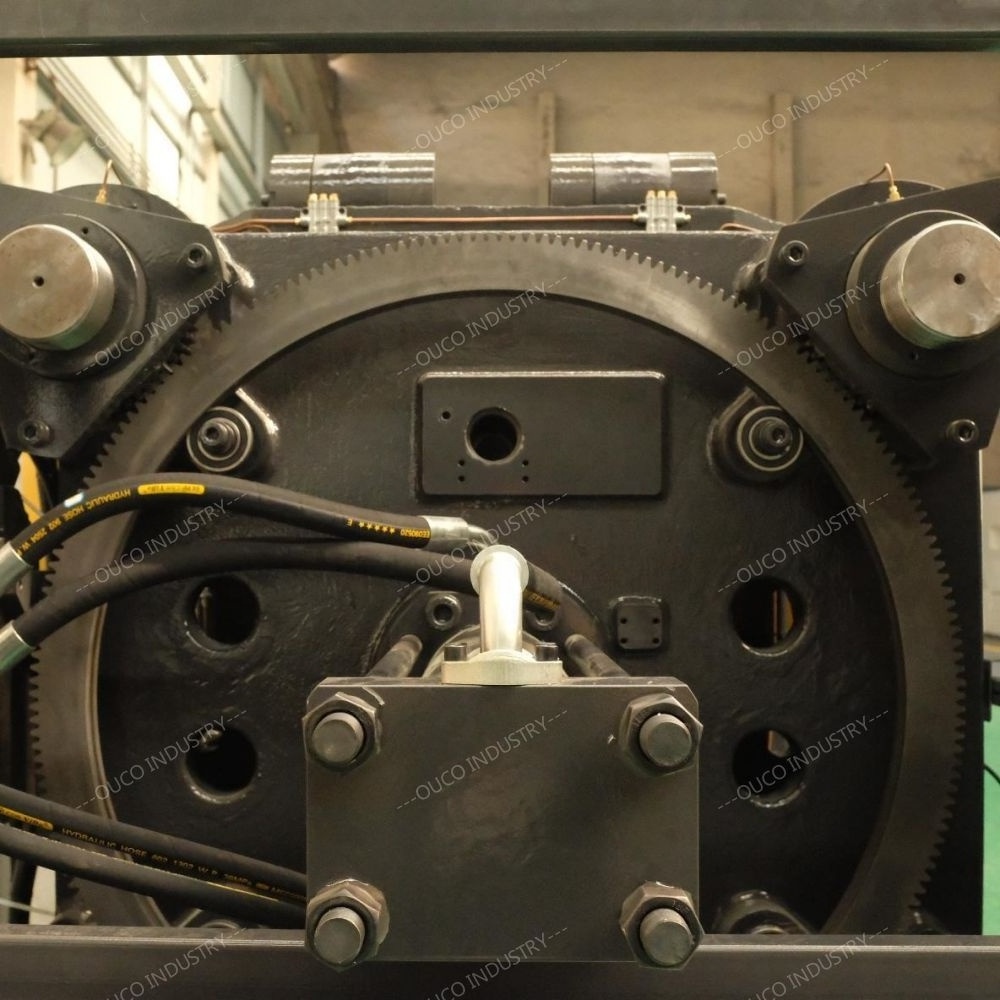

Dual-cylinder injection technology, providing smooth, precise, and fast injection.

Taiwan's Grand Vision Computer, touch-screen operation.

High-precision controller significantly reduces molding cycle.