- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 380V

-

Power:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

500

-

Key words 1:

-

Powder Painting Line For Metal

-

Keywords 2:

-

Powder Painting Line

-

Keywords 3:

-

Automatic Powder Painting Line

-

Application:

-

Industries

-

Usage:

-

Powder Coating Workpieces

-

Conveyor chain:

-

Customized Speed

-

Heating energy:

-

Naturel Gas

-

Powder recovery rate:

-

99%

Quick Details

-

Machine Type:

-

Metal surface treatment machine, Spray Booths, Painting Equipment, Drying Oven, Coating Equipment

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hanna

-

Voltage:

-

380V, 380V

-

Power:

-

CUSTOMIZED

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

500

-

Key words 1:

-

Powder Painting Line For Metal

-

Keywords 2:

-

Powder Painting Line

-

Keywords 3:

-

Automatic Powder Painting Line

-

Application:

-

Industries

-

Usage:

-

Powder Coating Workpieces

-

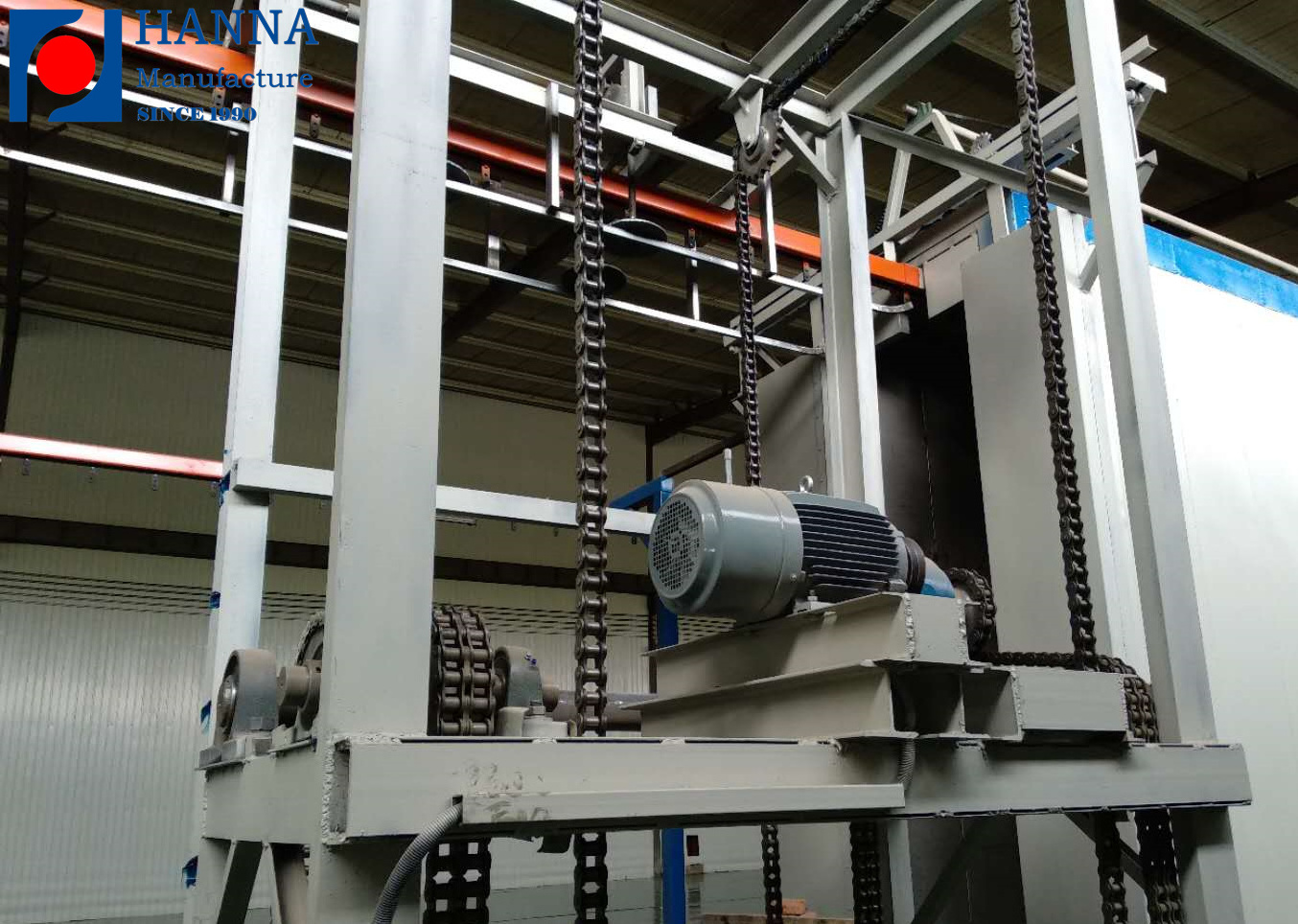

Conveyor chain:

-

Customized Speed

-

Heating energy:

-

Naturel Gas

-

Powder recovery rate:

-

99%

We make it easy for you to be our customer

We have more than three decades of experience

Product Description

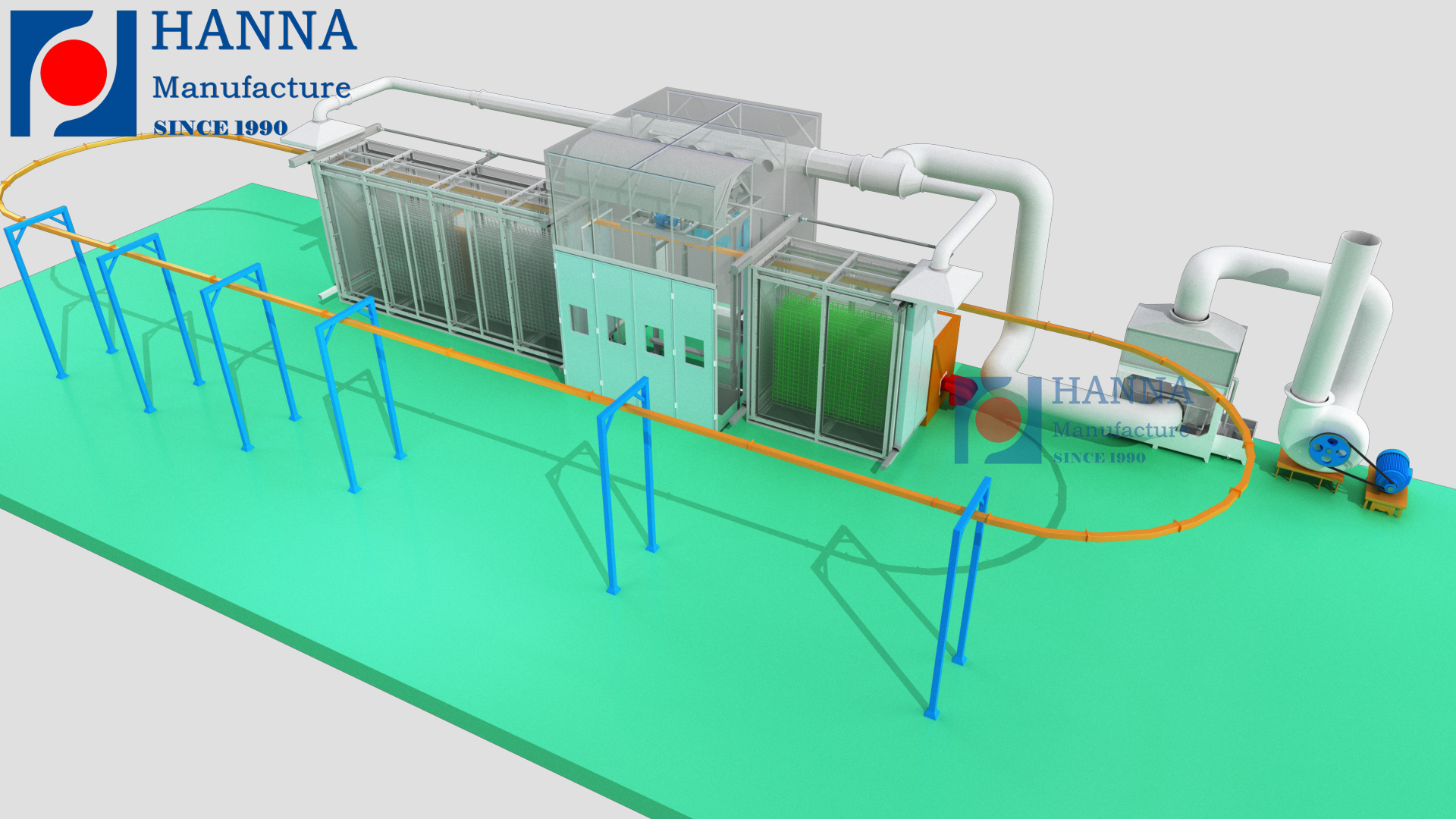

We cover all industries- almost

Auto parts;Aluminum Profiles;Agricultural Machinery;Off-high way Machinery;Home Appliances;Indoor Equipment;Shop Equipment;Outdoor Machinery and Products

Powder PVC Coating Automated Line for Fence Mesh Panel With Fluidized Bed Coating

Automatic Powder Spraying Line

Application and use

The conveyor system works in all environments up to 250oC.

Function

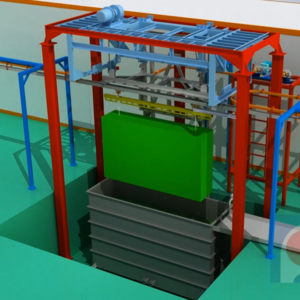

The products or items are hanging from the chain in suitable jigs; one or more driving units pulls them through the line.

The number of driving units needed depends on the maximum load of the conveyor and the geometry of the overall layout of the line.

In order to compensate for heat expansion and wear, the systems are equipped with pneumatic expansion units.

Powder PVC Coating Automated Line for Fence Mesh Panel With Fluidized Bed Coating

Construction

The chain has smooth-running wheels and runs in the c-profile. For each link in the chain, a product or item can be hung or a fixture can be mounted. The profile can be turned with the opening upwards to avoid pollution of the products from the chain/rail.

One or more driving units pulls the chain, and they are constructed to transmit maximum power to the chain and give minimum abrasion.

The speed of the chain can be steples adjusted by means of a frequency inverter. A pneumatic tensioning device keeps the chain

tense.

Specification

|

ELectrical Data

|

|

|

|

Nominal input voltage

|

110V240VAC

|

|

|

Frequency

|

50-60Hz

|

|

|

Connected load (without vibrator)

|

140 VA

|

|

|

Nominal output voltage (to the gun)

|

eff.10 V

|

|

|

Nominal output current (to the gun)

|

max. 1.2 A

|

|

|

Connection and output for vibrator (on Aux output)

|

110/230 VAC max. 100 W

|

|

|

Connection for rinsing function (valve)

|

24 VDC max. 3 W

|

|

|

Temperature range

|

0°C - +40°(+32°F - +104°F)

|

|

|

Max. surface temperature

|

120 °C (+248 °F)

|

|

|

Approvals

|

120 °C (+248 °F)

|

|

Product Technical Information

Manufacturing Process

Automatic Loading-----Powder coating----Curing----Automatic Unloading

Standard Systems

Double sandwich spray chamber, engineering plastic, engineering plastic board thickness &8mm &6mm, sandwich interlayer thickness is 120mm.

Large cyclone automatic color changing system with powder recovery function.

the energy radiated to the workpiece is absorbed and converted into heat, thus solidifying the coating.

Powder feeding centre

The powder center is specially designed for quick color change, instead of the traditional powder barrel.

Power & free conveyor chain

Working Live-Action

Powder PVC Coating Automated Line for Fence Mesh Panel With Fluidized Bed Coating

Oversea Installation Team

We always pay more attention to the quality of

Powder Coating Plant

.Standard quality control team are responsible to insure the quality in every step with different instruments. We have professional equipment to inspect the finish goods quality and he temperature for the furnance oven.

Packing&Shipping

Certification

Our Certification & Customer

Guarantee And After-sales Service

* Two years guarantee for whole machine

* 24 hours technical support service

* Calling or door to door service

Powder PVC Coating Automated Line for Fence Mesh Panel With Fluidized Bed Coating

About Us

Hot Searches