1)Tension control: magnetic powder tension

2)Wire-broken, stop automatically

3)Handling mode: lifting by electricity

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

JCJX

-

Name:

-

electrical wire and cable making equipment

-

Application:

-

insulation of flat cable

-

Color:

-

Customized

-

Power:

-

90/110/132/160/250

-

Certification:

-

ISO9001:2008

-

Type:

-

electrical wire and cable making equipment

-

Function:

-

wire and cable extrusion line

-

Feature1:

-

high capacity

-

Feature2:

-

change color quickly

-

After-sales service:

-

Online Support/Enigneer

Quick Details

-

Use:

-

insulation

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIACHENG

-

Model Number:

-

JCJX

-

Name:

-

electrical wire and cable making equipment

-

Application:

-

insulation of flat cable

-

Color:

-

Customized

-

Power:

-

90/110/132/160/250

-

Certification:

-

ISO9001:2008

-

Type:

-

electrical wire and cable making equipment

-

Function:

-

wire and cable extrusion line

-

Feature1:

-

high capacity

-

Feature2:

-

change color quickly

-

After-sales service:

-

Online Support/Enigneer

Product Description

|

Main technical parameter

|

Screw Parameters

|

|

|

Extrusion Capacity (kg/h)

|

|

|

|

|||||

|

|

Dia(mm)

|

L/D Ratio

|

Ratation Speed(r/min)

|

PVC

|

LDPE

|

PP

|

|

|||||

|

JCJX-30 Extrusion

|

Φ30

|

25:1

|

20-110

|

25

|

16

|

13

|

|

|||||

|

JCJX-40 Extrusion

|

Φ40

|

25:1

|

20-110

|

40

|

20

|

17

|

|

|||||

|

JCJX-50 Extrusion

|

Φ50

|

25:1

|

20-110

|

80

|

40

|

34

|

|

|||||

|

JCJX-60 Extrusion

|

Φ60

|

25:1

|

15-110

|

100

|

53

|

41

|

|

|||||

|

JCJX-70 Extrusion

|

Φ70

|

25:1

|

15-110

|

130

|

86

|

68

|

|

|||||

|

JCJX-80 Extrusion

|

Φ80

|

25:1

|

10-90

|

200

|

122

|

96

|

|

|||||

|

JCJX-90 Extrusion

|

Φ90

|

25:1

|

10-80

|

240

|

133

|

124

|

|

|||||

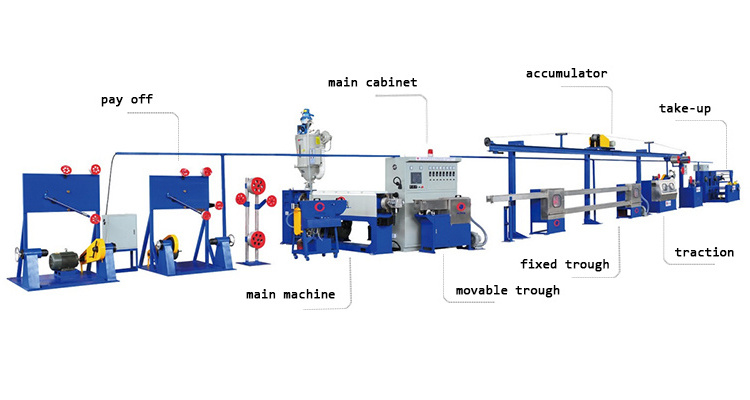

Structure and Details

Φ630 Single-spooler passive Pay-off without axis

SAL-300C Auto material feeder

1) Type: SAL-300C;

2) Motor: carbon brush,1000W;

3) Transport capacity: 300kg/h;

4) Hopper capacity: 6L;

5) Weight: 11kg.

2) Motor: carbon brush,1000W;

3) Transport capacity: 300kg/h;

4) Hopper capacity: 6L;

5) Weight: 11kg.

Straightening table

1) Straightening direction: one-way

2) Straightening wheel, it can be adjusted up and down

3) With tool box

2) Straightening wheel, it can be adjusted up and down

3) With tool box

Electric control/Operation panel

All computer control system(HMI),

(1) Heating temperature

(2) Power Control

(3) Motor operation control

(4) ......

(1) Heating temperature

(2) Power Control

(3) Motor operation control

(4) ......

Φ70×25D Main Extruder Machine

1) Machine head: adjustable, free of the head(1 group), the nose temperature in two, head 1 section, eye model 1 section

2) The head of imported heat-resistant anti-corrosion alloy steel(Hitachi SKD61 and 718), oxidized, hard chrome plated

2) The head of imported heat-resistant anti-corrosion alloy steel(Hitachi SKD61 and 718), oxidized, hard chrome plated

1.2m Activity trough

1) The primary role that cool inside the cable rapidly

2) With two drying device: stainless steel frame can be adjusted up and down; stainless steel bearing, guide wheel can be adjusted up and down

2) With two drying device: stainless steel frame can be adjusted up and down; stainless steel bearing, guide wheel can be adjusted up and down

8m Fixed trough

1) Material: SUS304 stainless steel

2) Groove: U-type stainless steel sink

3) After the upper and lower front 4 meters 4 meters

2) Groove: U-type stainless steel sink

3) After the upper and lower front 4 meters 4 meters

12m horizontal wire accumulator

2) Power: 2HP Gear Motor(Taiwan CPG) Ratio 1:30 with magnetic clutch and 10KG

3) Transmission: multi-core type cable

4) Accumulating wire length: 10~200m

7) Double checking devices: Detection of non-contact linear displacement sensor

8) Safety device: Front and rear set limit switches, emergency stop control synchronization break

9) Controlling cabinet: position in the storage line stand at the steering wheel into line, control: 1.1KW

power motor control and reverse switch under the tension adjustment VR, tension amp instruction sheet,

the power indiator

3) Transmission: multi-core type cable

4) Accumulating wire length: 10~200m

7) Double checking devices: Detection of non-contact linear displacement sensor

8) Safety device: Front and rear set limit switches, emergency stop control synchronization break

9) Controlling cabinet: position in the storage line stand at the steering wheel into line, control: 1.1KW

power motor control and reverse switch under the tension adjustment VR, tension amp instruction sheet,

the power indiator

Double-wheel hual-off

1) Motor: 2.2KW, 5HP motor

2) Type: water tank with two wheels

3) Maximum Take-line speed: 350m/Min(determined by the completion OD)

4)water tanks installed in CAPSTAN outlet end of the cable using high pressure air to dry the surface

of the water to keep the scene clean

5)air pressure can be adjusted,with a group switch, adjust the air pressure size

6) specially designed to lead to take the alignment between the meter wheel, cited with U-groove to take the water tank to facilitate the rapid production of alignment

2) Type: water tank with two wheels

3) Maximum Take-line speed: 350m/Min(determined by the completion OD)

4)water tanks installed in CAPSTAN outlet end of the cable using high pressure air to dry the surface

of the water to keep the scene clean

5)air pressure can be adjusted,with a group switch, adjust the air pressure size

6) specially designed to lead to take the alignment between the meter wheel, cited with U-groove to take the water tank to facilitate the rapid production of alignment

Application

It's used for the insulation of wire&cable with

PVC.LDPE,NYLON,TPU

. Also it can be equipmented with triple co-extrusion crosshead and double layer

Finished Products

Single core bare wire extrusion cable

Multi core bare wires extrusion cable

Multi core extrusion cable

Packing&Shipping

After Sales Service

Pre-Sales Service

In order to guarantee the customers are able fully to operate the machine, if the customer need, we can help customer training,

includes:

(1) Correct operating mode

(2) Correct maintenance way

(3) Remove simple proble

includes:

(1) Correct operating mode

(2) Correct maintenance way

(3) Remove simple proble

After-Sales Service

①Free service guarantee period is: 12 months after shipping (except wearing parts)

② Provides long term spare supply, technical support and maintenance service for the machine, but we will charge for travel fee and other basic cost.

We guarantee when we get the information of the customer, our engineers will analyze immediately, then response as soon as possible, if need our engineers come, 24hours will be arrived inland, and one to two week oversea based on getting visa on time.

② Provides long term spare supply, technical support and maintenance service for the machine, but we will charge for travel fee and other basic cost.

We guarantee when we get the information of the customer, our engineers will analyze immediately, then response as soon as possible, if need our engineers come, 24hours will be arrived inland, and one to two week oversea based on getting visa on time.

Company Introduction

FAQ

Hot Searches