- Product Details

- {{item.text}}

Quick Details

-

certificate:

-

API 6A

-

Pressure:

-

high pressure

-

Working Temperature:

-

-18°C-121°C

-

product specification level:

-

psl1-4

-

Material class:

-

AA BB CC DD EE FF

-

performance requirement:

-

PR1-2

-

Medium:

-

oil gas mud

-

Approx.weight:

-

110-250kg

Quick Details

-

Weight (KG):

-

35

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sanmon

-

certificate:

-

API 6A

-

Pressure:

-

high pressure

-

Working Temperature:

-

-18°C-121°C

-

product specification level:

-

psl1-4

-

Material class:

-

AA BB CC DD EE FF

-

performance requirement:

-

PR1-2

-

Medium:

-

oil gas mud

-

Approx.weight:

-

110-250kg

Product Description

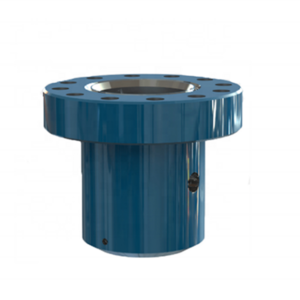

API 6A Oilfield Tubing head

Specification:

work pressure:2000-20000psi

work temp:-46-121

material class:AA-HH

Bottom Flange size(in): 7 1/16~11

product specification level: psl1-4

performance requirement: PR1-2

Bottom Connection: welded type, slips type, thread type.

Outlet connection: thread type, flange type(c/w VR plug thread).

Descriptions:

Tubing head is the equipment attached to the casing spool used to hang the tubing (smallest casing string) and seal the annular between the tubing and casing.

The top spool on a wellhead assembly contains the highest pressure in the wellhead, and contains a load shoulder to hang the tubing hanger and tubing string. When the well is completed, the tree is installed on top of the head with a tubing head adapter. Providing a means to support and test the BOPs while completing the well, the tubing head is a necessary component when drilling and completing a well. The standard tubing head product line combines a straight bore profile

with a varied number of aligning pins, depending on the chosen model. Sanmon’s tubing heads eliminate the “wedge locking” of the bowl protector, BOP test plugs, and tubing hangers. As additional advantages, valve removal (VR) threads are standard on all flanged or studded tubing head outlets, and if a 9” or larger top flange is required, the C-29 casing hanger can be used for casing-type completions.

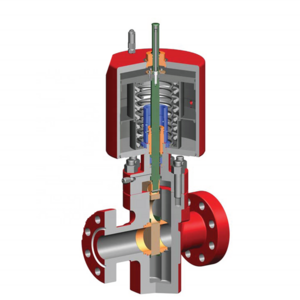

Lock-down screw - A mechanism that actuates the hanger/pack off seals in the event of annular pressure, preventing casing movement caused by thermal expansion during production.

Bottom Connections

Bolt-through flange, studded flange and clamp-hub connections are available. The type and pressure rating used must match the top flange of the previous casing spool or crossover flange. Bolt-through flange connections are the most popular and economical type of connection in certain parts of the world. Clamp hub connections are sometimes specified, because they are much faster to make up and because they reduce the diameter and weight of the assembly when space limitations are present.

Top Connections

Sanmon Surface Wellhead tubing heads have either bolt-through flange or clamp hub top connections, which are compatible with all Sanmon tubing head adapters. The producing pressure of the well normally determines the pressure rating of the top connection.

Tubing Heads feature a versatile straight bore design for single and multiple completions.

This design accepts all series tubing hangers and easily converts from a single completion to multiple completions with the addition and alignment pin(s).

Available Sizes

* Available with 7-1/16" nominal bowl

* Compatible with 7-5/8" production casing

Outlets

* Line Pipe Outlets

* Studded Side Outlets

Casing Hanger Compatibility

* C-21 and C-22 slip-type casing hangers

* Mandrel style casing hangers

Manufacturing Standard

* API-6A, PSL-1, DD, L-U, PR-1 (3M-5M)

* API-6A, PSL-2, DD, L-U, PR-1 (10M)

Tubing Hanger Compatibility

* TWC tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around

Bottom Preparations

* PE/BG bottom, for use with PE secondary seal bushing (Standard)

* HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request)

Availablility

* Additional sizes available upon request • Available with ET (Integral) style lock screws

* Flanged top Tubing Heads available with slip-on weld or threaded bottoms

This design accepts all series tubing hangers and easily converts from a single completion to multiple completions with the addition and alignment pin(s).

Available Sizes

* Available with 7-1/16" nominal bowl

* Compatible with 7-5/8" production casing

Outlets

* Line Pipe Outlets

* Studded Side Outlets

Casing Hanger Compatibility

* C-21 and C-22 slip-type casing hangers

* Mandrel style casing hangers

Manufacturing Standard

* API-6A, PSL-1, DD, L-U, PR-1 (3M-5M)

* API-6A, PSL-2, DD, L-U, PR-1 (10M)

Tubing Hanger Compatibility

* TWC tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around

Bottom Preparations

* PE/BG bottom, for use with PE secondary seal bushing (Standard)

* HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request)

Availablility

* Additional sizes available upon request • Available with ET (Integral) style lock screws

* Flanged top Tubing Heads available with slip-on weld or threaded bottoms

Specification

|

Bottom

Flange |

|

Top

Flange |

|

Dimensions

|

|

|

Weight

Lbs/Kg |

||||

|

|

|

|

|

A, inch / mm

|

B, inch / mm

|

C, inch / mm

|

|

||||

|

11"

|

2,000

|

7-1/16"

|

3,000

|

23.12/587.2

|

6.76/171.7

|

7.00/177.8

|

550/249

|

||||

|

|

3,000

|

7-1/16"

|

3,000

|

23.12/587.2

|

6.76/171.7

|

7.00/177.8

|

600/272

|

||||

|

|

|

|

5,000

|

26.25/666.8

|

6.76/171.7

|

7.00/177.8

|

670/304

|

||||

|

|

|

9"

|

3,000

|

26.25/666.8

|

8.25/209.6

|

8.75/222.3

|

750/340

|

||||

|

|

|

|

5,000

|

26.25/666.8

|

8.25/209.6

|

8.75/222.3

|

800/363

|

||||

|

|

5,000

|

7-1/16"

|

5,000

|

26.25/666.8

|

6.76/171.7

|

7.00/177.8

|

880/399

|

||||

|

|

|

|

10,000

|

31.25/793.8

|

6.76/171.7

|

7.00/177.8

|

856/388

|

||||

|

|

|

9"

|

10,000

|

31.25/793.8

|

8.25/209.6

|

8.75/222.3

|

1249/567

|

||||

|

|

10,000

|

7-1/16"

|

10,000

|

32.62/828.5

|

6.76/171.7

|

7.00/177.8

|

1318/598

|

||||

|

|

|

|

15,000

|

33.25/844.6

|

6.76/171.7

|

7.00/177.8

|

------

|

||||

|

|

|

9"

|

10,000

|

32.62/828.5

|

8.25/209.6

|

8.75/222.3

|

1700/771

|

||||

|

13-5/8"

|

2,000

|

7-1/16"

|

3,000

|

23.12/587.2

|

6.76/171.7

|

7.00/177.8

|

445/202

|

||||

|

|

|

9"

|

3,000

|

23.12/587.2

|

8.25/209.6

|

8.75/222.3

|

655/297

|

||||

|

|

3,000

|

7-1/16"

|

3,000

|

26.25/666.8

|

6.76/171.7

|

7.00/177.8

|

670/304

|

||||

|

|

|

|

5,000

|

26.25/666.8

|

6.76/171.7

|

7.00/177.8

|

805/365

|

||||

|

|

|

9"

|

3,000

|

26.25/666.8

|

8.25/209.6

|

8.75/222.3

|

705/320

|

||||

|

|

|

|

5,000

|

26.75679.5

|

8.25/209.6

|

8.75/222.3

|

715/324

|

||||

|

|

5,000

|

11"

|

10,000

|

30.25/768.4

|

10.00/254.0

|

10.88/276.4

|

1754/796

|

||||

Hot Searches