All the controlling operates by the software,convenience for function ad-justment and technical up grading

- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

220bag/mins

-

Weight (KG):

-

680

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HUAYUAN

-

Dimension(L*W*H):

-

4100x1050x1500mm

-

Materials:

-

Stainless Steel

-

Usage:

-

Food Snack

-

Controller:

-

PLC,inverter,servo motor controller

-

Film width:

-

Max.450mm

-

Packing speed:

-

40-250bag/mins

-

Product name:

-

Pillow Packing Machine

-

Keyword:

-

Pillow Packing Machine

Quick Details

-

Function:

-

Wrapping, Sealing

-

Packaging Type:

-

Bags, Film, Foil

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

220bag/mins

-

Weight (KG):

-

680

-

Voltage:

-

220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HUAYUAN

-

Dimension(L*W*H):

-

4100x1050x1500mm

-

Materials:

-

Stainless Steel

-

Usage:

-

Food Snack

-

Controller:

-

PLC,inverter,servo motor controller

-

Film width:

-

Max.450mm

-

Packing speed:

-

40-250bag/mins

-

Product name:

-

Pillow Packing Machine

-

Keyword:

-

Pillow Packing Machine

Products Description

|

Main Technical Parameters

|

|

|

|

|||

|

Model

|

KD-260B

|

KD-350B

|

KD-450B

|

|||

|

Bag length

|

60-200mm

|

60-250mm

|

60-300mm

|

|||

|

Package width

|

25-100mm

|

50-150mm

|

50-200mm

|

|||

|

Packing height

|

5-45mm

|

5-50mm

|

10-80mm

|

|||

|

lntensity of sealing (N/mm)

|

>15N mm

2

|

>15N mm

2

|

>15N mm

2

|

|||

|

Packaging speed

|

40-250packa/min

|

40-250packa/min

|

40-250packa/min

|

|||

|

Total power

|

220V、50Hz、2.4Kw

|

220V、50Hz、2.7Kw

|

220v、50Hz、2.7Kw

|

|||

|

Overall dimensions

|

4100×950×1500mm

|

4100×1000×1500mm

|

4100×1050×1500mm

|

|||

|

Weight

|

550kg

|

600kg

|

680kg

|

|||

|

Max. film width

|

260mm

|

350mm

|

450mm

|

|||

|

Max.Packaging capacity

|

20-250piece/min

|

20-220piece/min

|

20-200 piece/min

|

|||

|

Suitable for film thickness

|

0.03-0.06mm

|

0.03-0.06mm

|

0.03-0.06mm

|

|||

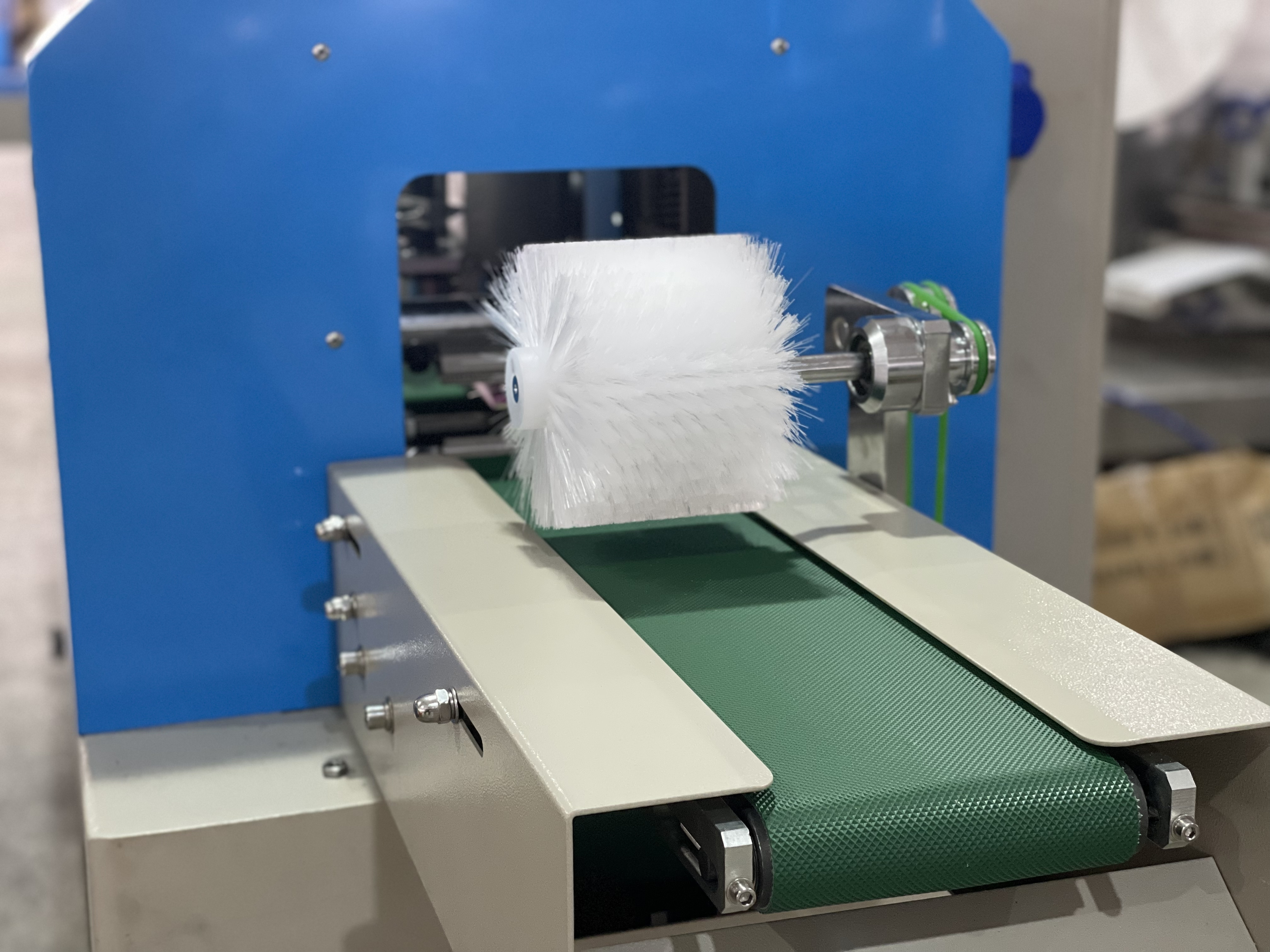

Performance and Characteristic

1.compact structure, stable performance and simple operation.

2.Independent research and development of three servo systems.The baglength is setand cut immediately without adjusting the air travel.The color mark of film exchange isin place one step, saving timeand saving film.

3.the imported electrical appliances and touch type human-machine interface areadopted, and the parameter setting is convenient and quick.

4.the fault self diagnosis function, the fault display is clear at a glance.

5.tracking with high sensitivity photoelectric eye color standard makes the sealingposition more accurate.

6. temperature independent PIlD control,better suitable for all kinds of material coating.

7.positioning the stop function, no sticking knife, no film.

8.the rotating system is simple, reliable and convenient for maintenance.

9.all control is realized by software,which is convenient for function adjustment andtechnical upgrading, and will never lag behind.

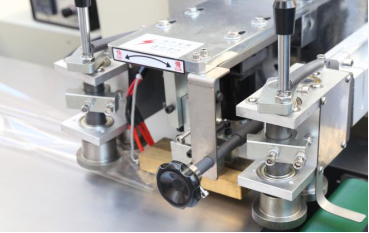

PLC touch screen

lt adopts imported electric appliance, touch man machine interface conv-enient parameter setting

Self-cheching function, trouble can be read easily

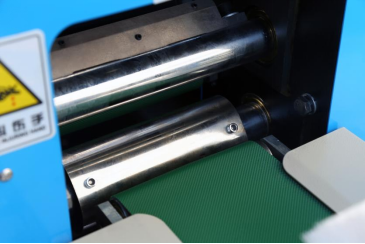

Sensor

High sensor photoelectric color chart tracking, make the cutting position more correctly

Cutter

Position stop function,no adhesive and no waste of membrane

Button

Ciean rotation system,more reliableoperation and more convenient maintenance.

The first third-generation double frequency control the bag could be set and cut, unnecessary adjust air without changing film color code tracking one pace reachs the designated position, il's saving lime and film.

Suitable for, packaging of all kinds of objects with regular solidstate, such, as biscuits bread, speed wheaten food, moon, cake,candy,

medicines,daily necessities,fivl metatspart, paper cartonor the tray, etc.

Solid objects with the rules package.

According to product customization.

Free proofing, welcome to cooperate

Why Choose Us

Hot Searches