Roller material:

High-quality 45# forged steel Forging process: polished, and high temperature treated.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0..2-0.6mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3.2*0.6*1.2m

-

Weight:

-

1300 kg

-

Feeding width:

-

Other

-

Product Name:

-

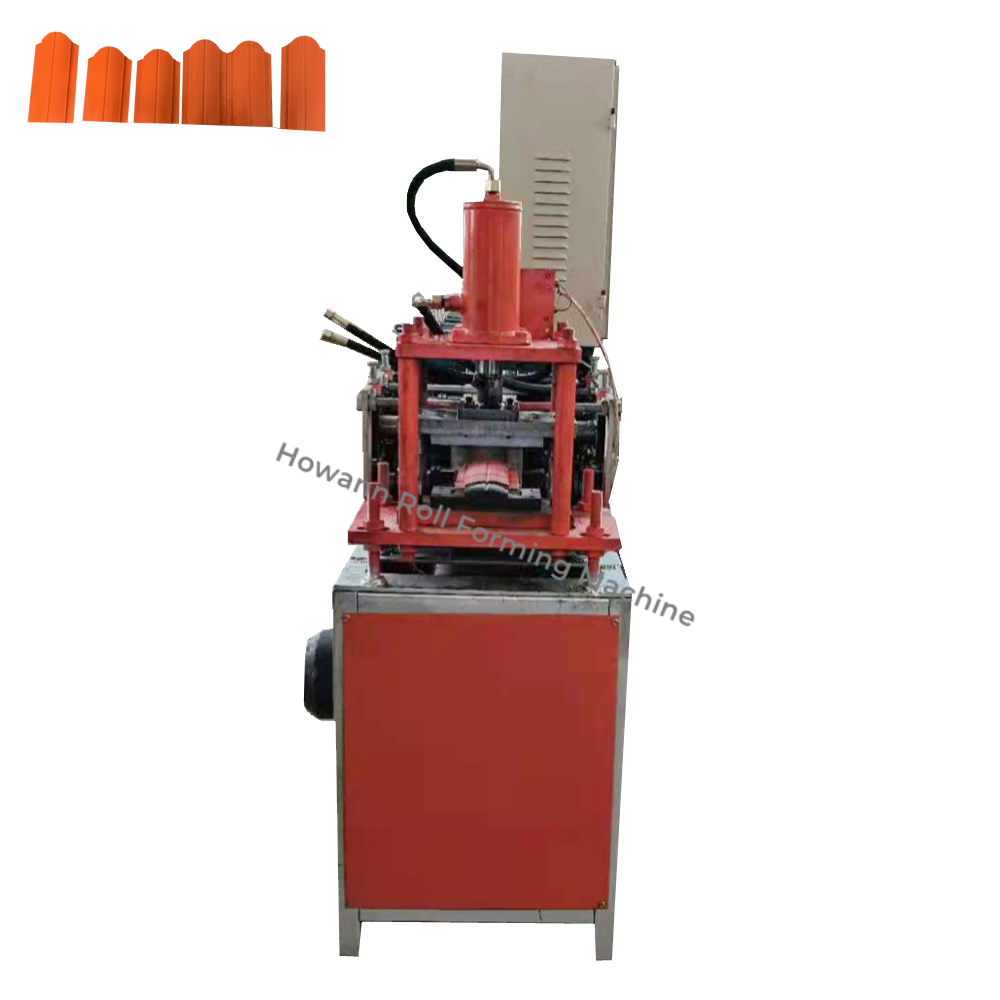

Palisade fence roll forming machine

-

Main Motor:

-

1.5KW

-

Roller Material:

-

45 # steel

-

Shaft Diameter:

-

40mm

-

Cutting Blade Material:

-

Cr 12 High Grade Steel

-

Hydraulic Power Station:

-

3KW

-

PLC:

-

Siemens

-

Main Frame:

-

350H Steel

-

Raw Material:

-

PPGI, PPGL, GI, GL

-

Certificate:

-

CE, ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-20m/min

-

Rolling thinckness:

-

0..2-0.6mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3.2*0.6*1.2m

-

Weight:

-

1300 kg

-

Feeding width:

-

Other

-

Product Name:

-

Palisade fence roll forming machine

-

Main Motor:

-

1.5KW

-

Roller Material:

-

45 # steel

-

Shaft Diameter:

-

40mm

-

Cutting Blade Material:

-

Cr 12 High Grade Steel

-

Hydraulic Power Station:

-

3KW

-

PLC:

-

Siemens

-

Main Frame:

-

350H Steel

-

Raw Material:

-

PPGI, PPGL, GI, GL

-

Certificate:

-

CE, ISO

Product Description

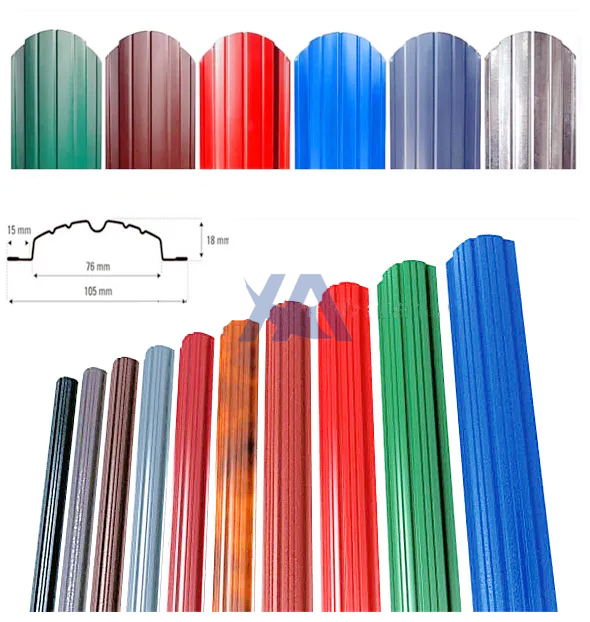

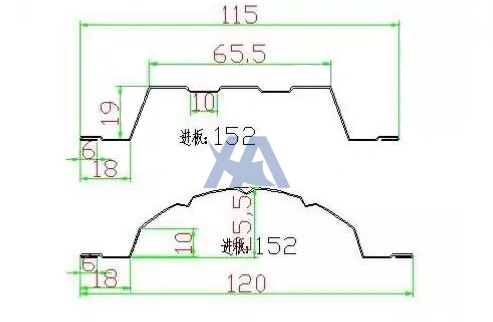

Palisade fence roll forming machine

can produce a metal fence that is stronger and more aesthetically pleasing than plastic fencing, which not only looks great, but better protects your yard. You can customize your products according to your needs, and customize the version you like.

|

value

|

||

|

Type

|

Palisade fence roll forming machine

|

|

|

Use

|

Metal Fence

|

|

|

Production Capacity

|

8-20M/MIN

|

|

|

Voltage

|

380v

|

|

|

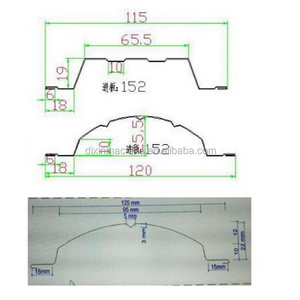

Rolling thinckness

|

0.2-0.6mm

|

|

|

Raw material

|

Steel Coil GI PPGI

|

|

|

Cutting

|

Hydraulic Guide Pillar

|

|

|

Roller material

|

Cr12Mov

|

|

|

Shaft material

|

45# steel

|

|

|

Shaft diameter

|

40MM

|

|

|

Dimension(L*W*H)

|

3.2*0.6*1.2m

|

|

|

Weight

|

1300kg

|

|

Our

Advantanges:

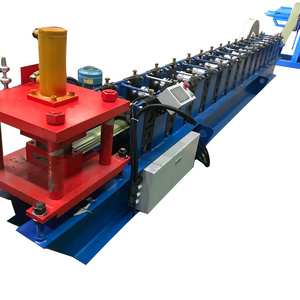

1. Main-machine interface touch screen for easy operation

2. Automatic material feeding system

3. The machine can be used for different type of fence

4. Automatic electric control system make production safety ang efficiency

5. Solid shaft and high quality rollers make the machine working smoothly and endurable

6. Low noise,low wasting ,energy saving and environmental

The Working Flow

Manual uncoiler---feeding device---rolling form---speed, length, pieces set by PLC---hydraulic mold post cutting---collection table

Details Images

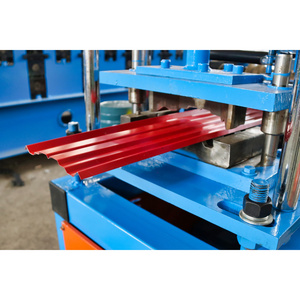

Stepless shearing system after forming, no need for shearing tool change, manual changeover

The board surface is flat, no wrinkles, no scratches, and the molding effect is good.

We can process the machine according to customers' demand and also can give professional suggestions if the customers need~

If you are interested in our products, please do not hesitate, you can contact us directly, I believe we will have a good cooperation.

WhatsApp: +8615036181512 E-mail: eva@howann.cn

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches