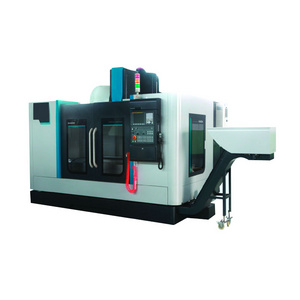

- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

900

-

Dimension(L*W*H):

-

6300x4300x3500

-

Weight (T):

-

16 T

-

Spindle Motor Power(kW):

-

22

-

Max. Table Load(kg):

-

1200 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hoton

-

Voltage:

-

Customer's Requirement

-

After-sales Service Provided:

-

Overseas third-party support available

-

Application:

-

General Machinery Processing

-

Machine Type:

-

CNC Horizontal Machining Center

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Spindle speed:

-

8000 Rpm

-

Model Number:

-

CNC Machine Center

-

Weight:

-

16000KG

-

Power:

-

22KW

-

Product name:

-

HMC630

Quick Details

-

Table Size (mm):

-

630x630

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

1100

-

Table Travel (Y) (mm):

-

900

-

Dimension(L*W*H):

-

6300x4300x3500

-

Weight (T):

-

16 T

-

Spindle Motor Power(kW):

-

22

-

Max. Table Load(kg):

-

1200 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hoton

-

Voltage:

-

Customer's Requirement

-

After-sales Service Provided:

-

Overseas third-party support available

-

Application:

-

General Machinery Processing

-

Machine Type:

-

CNC Horizontal Machining Center

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Spindle speed:

-

8000 Rpm

-

Model Number:

-

CNC Machine Center

-

Weight:

-

16000KG

-

Power:

-

22KW

-

Product name:

-

HMC630

This machine tool is a double-station horizontal machining center, which adopts a T-shaped bed and is controlled by FANUC CNC system.It has functions such as automatic exchange of worktables, automatic indexing of turntables, and infinitely variable speed of spindles.It can make Straight line, diagonal and arc interpolation cutting, finish milling, boring,drilling,reaming,tapping etc to achieve four-side processing.It is suitable for the machining of box parts and complex parts in automobile, aerospace, metallurgical mining, machine tool manufacturing and so on.Machine tool has the characteristics of high efficiency, high precision, high rigidity and so on. It is an efficient equipment for enterprises to improve working efficiency and improve flexible machining of parts. It is also an ideal equipment for machining large and medium batches of parts.

|

Model

|

|

|

|

|

HMC630

|

Unit

|

||||

|

Table

|

Table size

|

|

|

|

630×630

|

mm

|

||||

|

|

quantity

|

|

|

|

1

|

pc

|

||||

|

|

Max. Load

|

|

|

|

1200

|

Kg

|

||||

|

|

Table

|

|

|

|

T slot

|

mm

|

||||

|

|

Minimum division unit

|

|

|

|

1°

|

degree

|

||||

|

|

Highest speed of turntable

|

|

|

|

16.7

|

rpm

|

||||

|

Machining range

|

Maximum column travel - X axis

|

|

|

|

1100

|

mm

|

||||

|

|

Maximum travel of headstock - Y axis

|

|

|

|

900

|

mm

|

||||

|

|

Maximum travel of table - Z axis

|

|

|

|

1000

|

mm

|

||||

|

|

Maximum workpiece turning diameter

|

|

|

|

1000

|

mm

|

||||

|

|

Distance from spindle axis to work table

|

|

|

Max.

|

950

|

mm

|

||||

|

|

|

|

|

Min.

|

50

|

mm

|

||||

|

|

Distance from the center of the table to

the front end of the spindle |

|

|

Max.

|

1200

|

mm

|

||||

|

|

|

|

|

Min.

|

200

|

mm

|

||||

|

Spindle

|

Taper (7:24)

|

|

|

|

BT50

|

|

||||

|

|

Highest speed

|

|

|

|

10000

|

r/min

|

||||

|

|

Max. Output torque

|

|

|

|

260

|

N·m

|

||||

|

|

withstand the maximum axial resistance

|

|

|

|

18000

|

N

|

||||

|

|

Motor power

|

|

|

|

22

|

Kw

|

||||

|

|

quill dia.

|

|

|

|

Φ190

|

mm

|

||||

|

|

max. Tapping dia.

|

casting

|

|

|

M20

|

mm

|

||||

|

|

|

Carbon Steel

|

|

|

M16

|

|

||||

|

Feed system

|

X、Y、Z servo motor power

|

|

|

|

7

|

Kw

|

||||

|

|

B axis servo motor power

|

|

|

|

4

|

Kw

|

||||

|

|

Cutting feed speed range

|

|

|

|

1-12000

|

mm/min

|

||||

|

|

Rapid feed

|

X

|

|

|

60000

|

mm/min

|

||||

|

|

|

Y

|

|

|

60000

|

|

||||

|

|

|

Z

|

|

|

60000

|

|

||||

|

Tool magazine

|

type

|

|

|

|

Manipulator type

|

|

||||

|

|

capacity

|

|

|

|

20/24

|

pcs

|

||||

|

|

Max. Tool dia.

|

|

|

|

125/250

|

mm

|

||||

|

|

Max. Tool length

|

|

|

|

400

|

mm

|

||||

|

|

Max. Tool weight

|

|

|

|

25

|

kg

|

||||

|

|

Tool change time (tool-tool)

|

|

|

|

4.7

|

s

|

||||

|

Positioning accuracy |

Standard

GB/T 18400.4 |

|

X

|

|

0.008

|

mm

|

||||

|

|

|

|

Y

|

|

0.008

|

|

||||

|

|

|

|

Z

|

|

0.008

|

|

||||

|

|

|

|

B

|

|

8

|

arcsec

|

||||

|

Repeat positioning accuracy

|

Standard

GB/T 18400.4 |

|

X

|

|

0.004

|

mm

|

||||

|

|

|

|

Y

|

|

0.004

|

|

||||

|

|

|

|

Z

|

|

0.004

|

|

||||

|

|

|

|

B

|

|

2

|

arcsec

|

||||

|

Cnc controller

|

type

|

|

|

|

FANUC 0i MF(1)

|

|

||||

|

|

Total number of controlled axes

|

|

|

|

5

|

Axes

|

||||

|

|

Number of linkage control axes

|

|

|

|

4

|

Axes

|

||||

|

Electrical requirements

|

Power Requirements

|

|

|

|

50KVA,3ph,380V,50HZ

|

|

||||

|

|

Air source requirements

|

|

|

|

0.5-0.7MPa

|

|

||||

|

Dimensions

|

Length

|

|

|

|

6300

|

mm

|

||||

|

|

Width

|

|

|

|

4300

|

mm

|

||||

|

|

Height

|

|

|

|

3500

|

mm

|

||||

|

|

Machine weight

|

|

|

|

16000

|

Kg

|

||||

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2. What about the lead time?

A: Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Q3: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance,balance before shippment. If you have another question, pls feel free to contact us as below.