The equipment we produce is of good quality and price, and is exported to all over the world with a good reputation. Our perfect after-sales service system can help customers solve all problems.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

25000*1500*2200

-

Year:

-

2023

-

item:

-

fish pet feed extruder

-

Function:

-

Producing Pet Puffed Food

-

Final product:

-

ball, stick, flower, core filling snack, etc.

-

type:

-

puff snack machine

-

Raw material:

-

corn flour, wheat flour, rice flour, etc.

-

Color:

-

Stainless Steel Color

-

Suitable for:

-

Snack Food Processing Plant

-

Product:

-

Pet Food Production Line Dog Food Making Machine

-

Usage:

-

Snack Food Processing Plant

-

Advantage:

-

Easy Operation High Performance

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V/440v

-

Power:

-

55kw

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

25000*1500*2200

-

Year:

-

2023

-

item:

-

fish pet feed extruder

-

Function:

-

Producing Pet Puffed Food

-

Final product:

-

ball, stick, flower, core filling snack, etc.

-

type:

-

puff snack machine

-

Raw material:

-

corn flour, wheat flour, rice flour, etc.

-

Color:

-

Stainless Steel Color

-

Suitable for:

-

Snack Food Processing Plant

-

Product:

-

Pet Food Production Line Dog Food Making Machine

-

Usage:

-

Snack Food Processing Plant

-

Advantage:

-

Easy Operation High Performance

Product Information

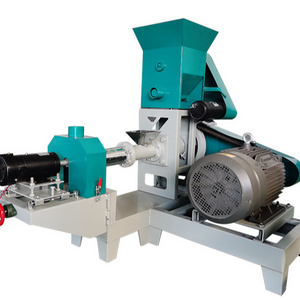

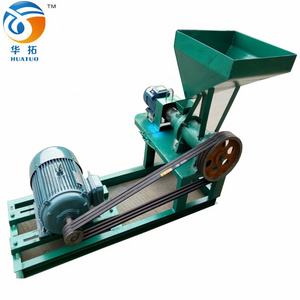

Pet Poultry Animal Food Making Machine Feed Mixing Pellet Extruder Packing Floating Sinking Fish Feed Processing Production Line

It is a newly-designed processing for improving market of dog food, floating fish pellets, which is developed successfully with our many years research experiences on food machinery.

This dog food making machine endues pet food with novel shape, unique taste and color. It can meet with other needs of modern market by many superior characteristics, such as scientific nutrition formular and easy assimilation.

And this do food making machine can also make the pet food cored filling, it will be more popular with modern pets.

|

Model

|

Capacity

|

Screw Diameter

|

Main Power

|

Feeding Power

|

Cutting Power

|

|

DF-40

|

30-40kg/h

|

40mm

|

5.5kw

|

0.4kw

|

0.4kw

|

|

DF-50

|

60-80kg/h

|

50mm

|

11kw

|

0.4kw

|

0.4kw

|

|

DF-60

|

120-150kg/h

|

60mm

|

15kw

|

0.4kw

|

0.4kw

|

|

DF-70

|

180-250kg/h

|

70mm

|

18.5kw

|

0.4kw

|

0.4kw

|

|

DF-80

|

300-350kg/h

|

80mm

|

22kw

|

0.4kw

|

0.6kw

|

|

DF-90

|

400-450kg/h

|

90mm

|

37kw

|

0.4kw

|

1.5kw

|

|

DF-120

|

500-700kg/h

|

120mm

|

55kw

|

0.4kw

|

2.2kw

|

|

DF-135

|

700-800kg/h

|

133mm

|

75kw

|

0.4kw

|

2.2kw

|

|

DF-160

|

1.2-1.5t/h

|

155mm

|

90kw

|

0.75-1.1kw

|

3.0kw

|

|

DF-200

|

1.8-2t/h

|

195mm

|

132kw

|

1.5kw

|

3.0-4.0kw

|

|

1

|

Screw sleeve use 40 Cr as materials,with high hardness and good durability

|

|

2

|

The sleeve includes two layers including the internal sleeve and outer sleeve. If abrasion, the customers just need to replace the internal sleeve to save maintain cost

|

|

3

|

Raw materials feeding motor and feed pellet cutting motor are adjustable speed motor,customer could adjust the feeding speed and final pellet shape according to needs.

|

|

4

|

The machine is with the temperature controller which can control the temperature of machine, the main factor for making floating fish food pellets is to control the temperature.

|

|

5

|

The machine with large hopper for feed materials well.

|

|

6

|

The machine work with electric cabinet ,customers can control the machine conveniently.

|

Final products features

1)The pellet can float on the water at least for 12 hours. no water pullation.

2)The feed pellet diameter can be 0.9-8mm,length adjustable.

3) The pellet smooth, nutrition

Our hydroponic Floating Fish Feed Mill is based on the Raw material of corn meal, flour, Wheat middling, Wheat bran, rice bran, soybean meal, cottonseed meal, fish meal, bone meal, meat meal and etc.

------ Moisture of raw material: 20% -25%

------ Rawmaterial type: Powder

------ Feed pellets diameter is 1-12mm.

Main Use:

1. Aquatic feed pellet for fish, catfish, tilapia, tilapia fish, shrimp, crab, etc. Both floating and sinking feed pellets. The floating time can be adjusted by the different puffing degree.

2. Pet food pellet for pets like cat, dog, pet bird,

3. Other animals feed pellet, like frog, fox, rabbit, etc.

3. Other animals feed pellet, like frog, fox, rabbit, etc.

4. Poultry animals feed pellet, like chicken food, goose feed, sheep feed, etc.

Design of Fish Feed Formula

1. Before designing fish feed pellets formulation, we should make certain the species and growth stage of fish to determine the content of nutrients including protein, energy and so on.

2. The fish feed pellets formulation should not only meet the fish’s demand for protein, but also have a reasonable proportion of energy to protein, because too high or two low proportion of energy to protein will be bad for the growth of fish.

3. In addition to nutrition, satiety of fish should be also taken into consideration when formulating fish feed pellets. At different growth stage, the fish’s demand for nutrients is different, for example, the protein content of feed pellets for carp fry should be 43%-41%, fingerlings 37%-42%, and adult fish 28%-32%.

Related Products

About Us

Copany Profile

Tianjin Mikim

Energy Technique Company

is a high-tech enterprise integrating scientific research, design, manufacturing, installation and commissioning, and after-sales service. We have obtained more than 50 inoependent patent property riohts and have pased S09001 qualty manacement system certhcaton, CE certhicaton.

Packing & Delivery

FAQ

1. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

2. What can you buy from us?

Feed pellet mahcine,wood pellet machine,fish&pet feed extruder,snack food extruder,oil press machine

3. Why should you buy from us not from other suppliers?

Professional R&D team, serving overseas for 18 years, exporting to 168 countries, providing one-stop design, sales, and overseas installation!

That's the common questions my other customers asked me;

If you still have questions, please send me email;

If these solved all your questions, you can contact me for our cooperation beginning.

Always a pre-production sample before mass production; Always final Inspection before shipment;

2. What can you buy from us?

Feed pellet mahcine,wood pellet machine,fish&pet feed extruder,snack food extruder,oil press machine

3. Why should you buy from us not from other suppliers?

Professional R&D team, serving overseas for 18 years, exporting to 168 countries, providing one-stop design, sales, and overseas installation!

That's the common questions my other customers asked me;

If you still have questions, please send me email;

If these solved all your questions, you can contact me for our cooperation beginning.

Hot Searches