- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen

-

Voltage:

-

380V

-

Power:

-

350KW

-

Dimension(L*W*H):

-

35000*6500*6000mm

-

Weight:

-

300 kg

-

raw material:

-

waste cartons

-

output paper:

-

fluting paper,kraftliner paper

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

ISO

Quick Details

-

Production Capacity:

-

30Tons per day

-

Product Type:

-

waste paper recycle machine

-

Processing Type:

-

carton paper

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen

-

Voltage:

-

380V

-

Power:

-

350KW

-

Dimension(L*W*H):

-

35000*6500*6000mm

-

Weight:

-

300 kg

-

raw material:

-

waste cartons

-

output paper:

-

fluting paper,kraftliner paper

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

ISO

Product Description

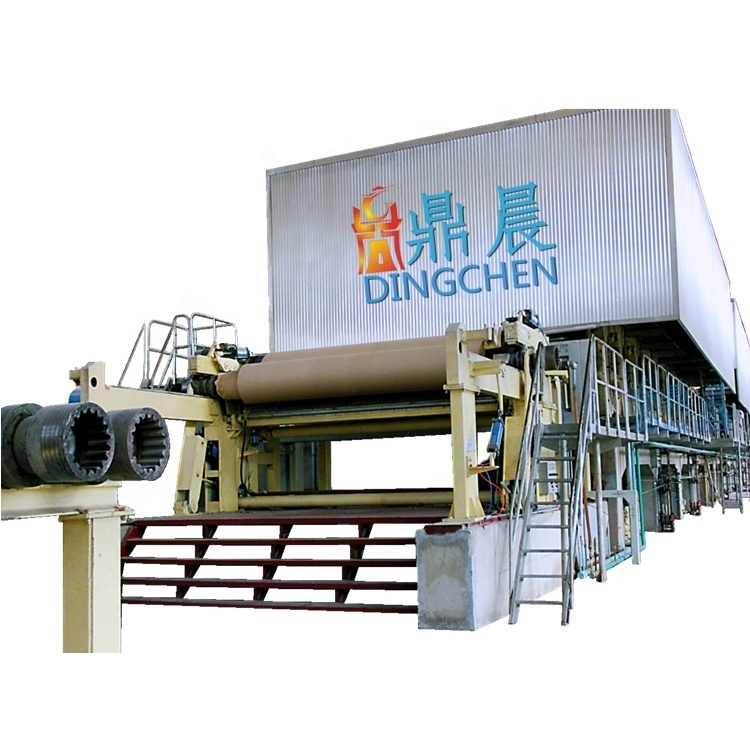

2400mm 30TPD Carton Paper Making Machine

(Waste Paper as Raw Material)

Technical parameter:

1. Raw material:Waste carton;OCC

2. Output paper: kraft liner paper,fluting paper,corrugated paper

3.Output paper weight: 100-200g/m2

4. Output paper width: 2400mm

5. Capacity: 30T/D

6. Drive way: A/C inverter speed control, sectional drive.

|

No.

|

Item

|

Function

|

||

|

Stock preparation section

|

|

|

||

|

1

|

D type Hydra-pulper

|

To break the waste paper into pulp and drop down the impurity and pins

|

||

|

2

|

High density pulp cleaner

|

To separate and sieve the small stone,staples,heavy impurity in the pulp

|

||

|

3

|

Fiber separator

|

To beating pulp again and separate long and short fiber

|

||

|

4

|

Reject separator

|

To separate and remove the small impurity(such as broken plastic tape,foam,etc)

|

||

|

5

|

Pulp refiner

|

To grind pulp fiber

|

||

|

6

|

Low concentration pulp cleaner

|

To remove the sand and tiny impurity in the water and pulp

|

||

|

7

|

Pressure screen

|

To screening pulp fiber

|

||

|

8

|

Impeller

|

To stir the pulp and make sure the pulp and water mixed well

|

||

|

9

|

Pulp pump

|

To provide the pulp for the needed machine

|

||

|

Paper making section

|

|

|

||

|

10

|

Cylinder mold part

|

To forming wet paper web

|

||

|

11

|

Vacuum dewatering part

|

To absorb the water in the wet paper

|

||

|

12

|

Press part

|

To dewatering by mechanical gravity press force

|

||

|

13

|

Dryer section part

|

To dry wet paper

|

||

|

14

|

Sizing press part

|

To glue paper surface to improve paper quality strength and stop printing ink spreading

|

||

|

15

|

Dryer section part

|

To dry paper after gluing wet

|

||

|

16

|

Calendering part

|

To glazing paper surface,control paper thickness,tightness

|

||

|

17

|

Winding part

|

To reeling output paper be a jumbo paper roll

|

||

|

18

|

Paper rewinding part

|

To rewind the jumbo roll paper to different size (width&diameter) according to your requirement

|

||

|

Boiler section

|

|

|

||

|

19

|

Gas/diesel/coal boiler

|

To provide high temperature and pressure steam to dryer to dry paper

|

||

Details Images

Product packaging

Carefully Packing,Reliable Fixing for Safety Delivery to Each Client

Recommend Products

Manufacturing Technique

Advanced production equipment, organized production process;

Technical experts involved in production to ensure the stability and reliability;

Increasing quality awareness and stringent quality control

CNC cutter

High efficient and high accuracy to cut steel plate

Head processing

Cast steel material with mirror processing craft

Lathe machine

Process kinds of roller outer surface

Rust remover

Use Iron pellets to spray at the raw part surface at a high speed to take down the attached rust on it

Machining center

CNC 5-Axis linkage Gantry machining center for planing,milling,boring,drilling

Balancing tester

To test and adjust the final part if is quietly running at high speed

Hot Searches