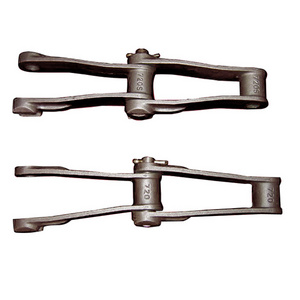

* The sidebars of the H type links are reinforced with wearing shoes which strengthen and stiffen the links when it is operated in troughs or over floors and runways.

* H type mill Chain is available in both riveted and cottered construction. T-head pins engage two lugs cast on the links. This configuration prohibits pin rotation during chain operation, eliminating abrasive wear and pitch

elongation.

* The chain may operate in two directions. As a drive chain, it travels in the direction of the closed bush; for elevator or conveyor applications, it should travel toward the open ends of the links.

* A wide assortment of attachments are also available for varied chain applications.

If you need technology support,

please contact with us

.