Material: Alloy steel.

Payment Terms: T/T, Western union,L/C....

Supply Ability: 150000PCS axles /50000sets suspensions each year.

MOQ: One container/50-60pics axle/5-12ets axle assembly.

Production Time: 15days.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XXY

-

Product Name:

-

Heavy Duty Trailer Accessories Twist Lock Trailer Truck Parts

-

Material:

-

Steel

-

Application:

-

Trailer Truck Used

-

Color:

-

Customer Demands

-

MOQ:

-

10pcs

-

Package:

-

Standard Package

-

Certificate:

-

ISO/TS16949

-

Quality:

-

High-Quality

-

Finish:

-

Painted

-

Weight:

-

10.50kgs / 15.50kgs / 7.50kgs

Quick Details

-

OE NO.:

-

OEM

-

Max Payload:

-

34000kgs

-

Size:

-

150x150x250mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XXY

-

Product Name:

-

Heavy Duty Trailer Accessories Twist Lock Trailer Truck Parts

-

Material:

-

Steel

-

Application:

-

Trailer Truck Used

-

Color:

-

Customer Demands

-

MOQ:

-

10pcs

-

Package:

-

Standard Package

-

Certificate:

-

ISO/TS16949

-

Quality:

-

High-Quality

-

Finish:

-

Painted

-

Weight:

-

10.50kgs / 15.50kgs / 7.50kgs

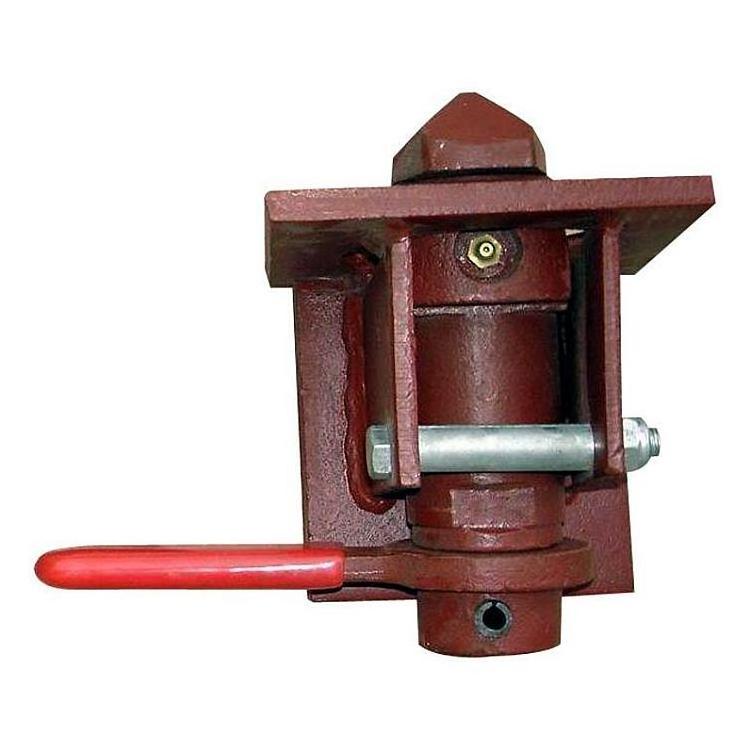

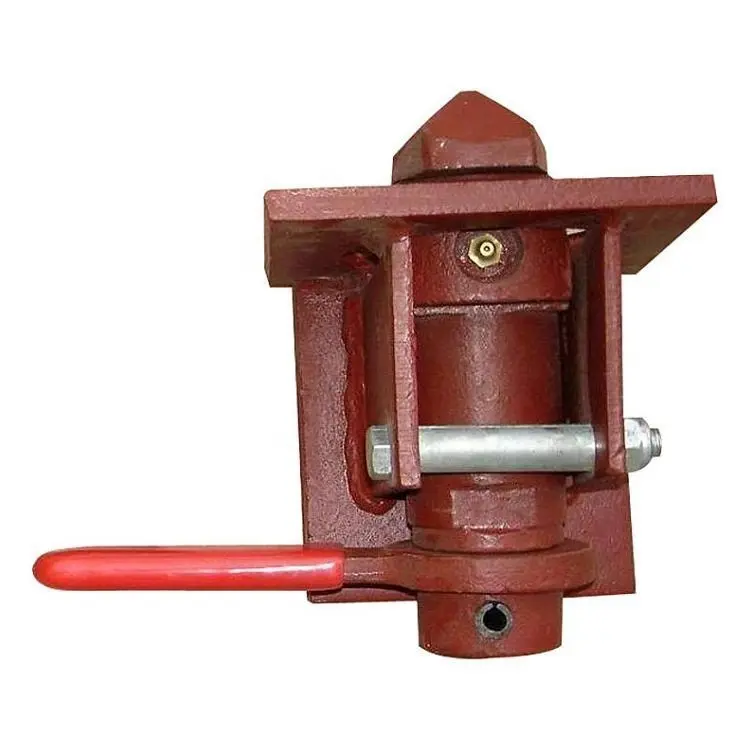

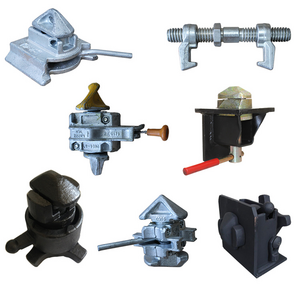

Product Overview

Heavy Duty Trailer Accessories Twist Lock Trailer Truck Parts

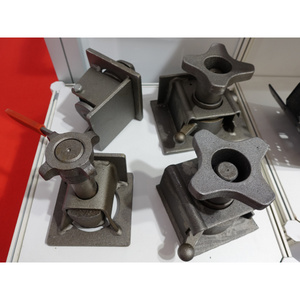

FORGED LOCK CENTER

the use of forged lock core, increase

the durability of the lock core. while improving the impact resistance

CASTING BODY

CASTING SHELL

so that the impact resistance of the product is strong while reducing weight.increase the service life of the product.

Details Images

Europe Trailer Twist Lock - Normal Light Type

(1)Weight: 10.5 kgs.

(2)Thickness of Housing Plate: 8 mm.

(3)Max Gross Weight of Container: 30500 kgs.

(4)Can be screwed down, Retractable.

(5)Application: Container Chassis

(2)Thickness of Housing Plate: 8 mm.

(3)Max Gross Weight of Container: 30500 kgs.

(4)Can be screwed down, Retractable.

(5)Application: Container Chassis

|

Each part can be customized according to customer requirements.

|

|

|

|

|

||||

When the container is hoisted to the vehicle carrying surface, the corner hole of the bottom of the container just falls on the position where the rotary lock is installed. By rotating the handle of the rotary lock, the lock will be fixed at a predetermined corner position (usually 90 degrees or 70). Degree), the lock is locked. For the lift type lock, the handle is pushed longitudinally to lift the lock head, extend into the inner cavity of the bottom corner of the container, and then rotate to apredetermined angle to lock the container angle. Some rotary locks have a tightening device. By tightening, the lock head can be pressed down to the bottom surface of the inner cavity of the corner piece to prevent the corner of the box from being lifted, thus ensuring that the locking is safer and more reliable.

Product Paramenters

Hot Searches