- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SQUARE

-

Dimension(L*W*H):

-

customized

-

Weight:

-

10000 KG

-

Product name:

-

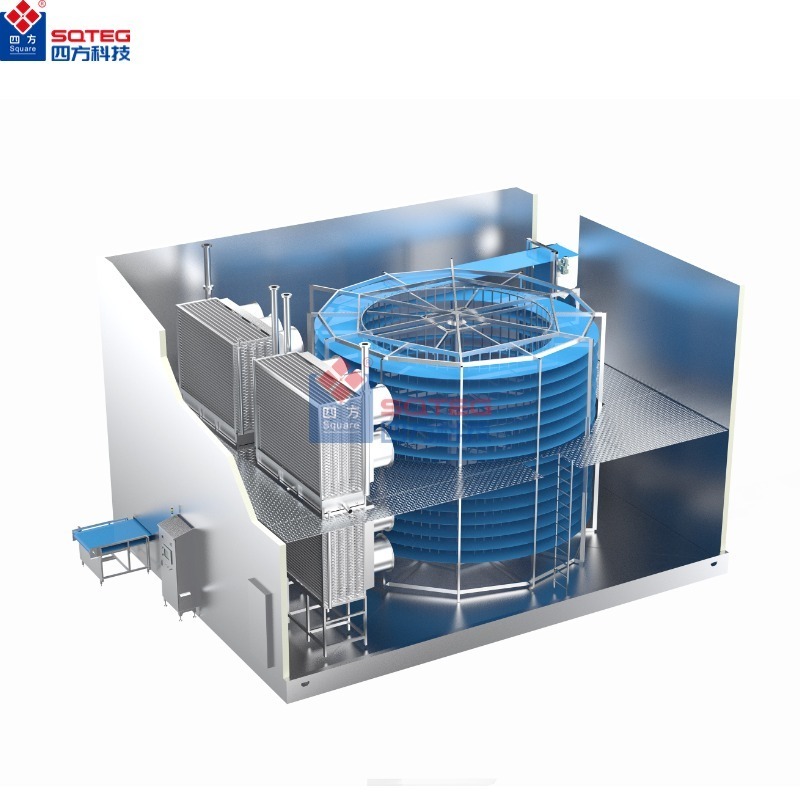

IQF Spiral Freezer

-

Application:

-

Food Quick Frozen Machine

-

Function:

-

Quick-freezing Food

-

Freezer Type:

-

Quicky Freeze Machine

-

Material:

-

Stainless Steel 304

-

Frozen products:

-

Fish Meat Seafood Fruit Vegetable

-

After-sales Service Provided:

-

Engineers

-

Feature:

-

High Freezing Effiency

-

Compressor:

-

Mycom Compressor

-

Advantage:

-

Low Consumption High Efficiency

Quick Details

-

Voltage:

-

local

-

Power:

-

customized

-

Cooling Capacity:

-

Customized 200kg/h to 10000kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SQUARE

-

Dimension(L*W*H):

-

customized

-

Weight:

-

10000 KG

-

Product name:

-

IQF Spiral Freezer

-

Application:

-

Food Quick Frozen Machine

-

Function:

-

Quick-freezing Food

-

Freezer Type:

-

Quicky Freeze Machine

-

Material:

-

Stainless Steel 304

-

Frozen products:

-

Fish Meat Seafood Fruit Vegetable

-

After-sales Service Provided:

-

Engineers

-

Feature:

-

High Freezing Effiency

-

Compressor:

-

Mycom Compressor

-

Advantage:

-

Low Consumption High Efficiency

|

Product Name

|

Single Spiral Freezer

|

|

Drum Diameter

|

1620~5800mm

|

|

Layers

|

6-40

|

|

Insulated Enclosure

|

PIR/PU, double sides stainless steel panel

|

|

Mesh Belt Width

|

520~1372mm

|

|

Infeed Length

|

500mm

|

|

Outfeed Length

|

500mm

|

|

Control Panel

|

PLC touch screen, SS panel

|

|

Refrigerant

|

Freon, Ammonia, CO₂

|

|

Evaporator

|

Al/SS tube, aluminum fin, variable fin pitch

|

|

Defrost

|

Water/hot /ADF optional

|

|

Freezing/Cooling Time

|

Stepless variable frequency adjustable

|

|

Cleaning

|

Manual\Belt\Washer\CIP

|

|

Freezing capacity

|

200kg to 10000kg/h

|

Finite Element Analysis

When Designing a spiral freezer, structural analysis is performed to ensure its structural integrity during operation

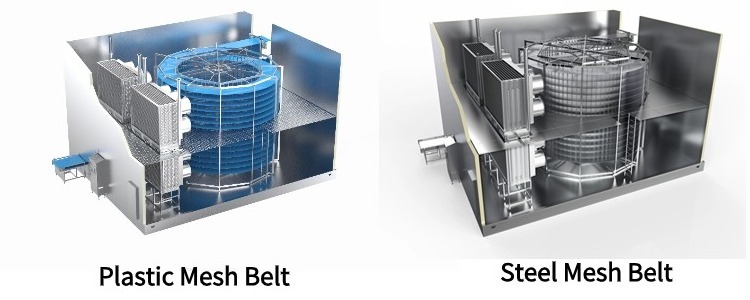

Stainless Steel Mesh Belt

SUS304 food-grade spring wire, high strength, 8–10 years of service life. Open structure, easy to clean, suitable width: 400–1372 mm. Optional edge guard board to prevent products from dropping. High ventilation, high efficiency.

CIP(Cleaning-in-place)

The system cleans and disinfects the interior of the freezer completely to meet the sanitary requirements of food safety

production.

production.

Belt Flip Detector

The Belt Flip Detector is a feature that helps to ensure the smooth and efficient operation of the spiral freezer. It works by detecting any issues with the conveyor belt that could cause it to flip or become misaligned. If a problem is detected, the Belt Flip Detector will automatically shut down the freezer to prevent any damage or downtime. This helps to reduce maintenance costs

and increase the overall reliability of the spiral freezer.

and increase the overall reliability of the spiral freezer.

Fully welded floor

Modular stainless steel fully welded floor, leak proof.

Sloped floor, fast drainage through four drains at the corners. Easy Access.

Sloped floor, fast drainage through four drains at the corners. Easy Access.

Multi-Zone Temperature Monitor

The Multi-Zone Temperature Monitor is a feature that allows you to monitor the temperature of different areas within the spiral

freezer. It is made up of several sensors that are strategically placed around the freezer to give real-time readings of the

temperature. This lets you keep track of how well the freezer is working and make any changes you need to for the best temperature control.

freezer. It is made up of several sensors that are strategically placed around the freezer to give real-time readings of the

temperature. This lets you keep track of how well the freezer is working and make any changes you need to for the best temperature control.

Efficient Evaporator

Our design was simulated with European professional heat exchanger software. All tubes are expanded hydraulically rather than

mechanically, which improves heat exchange performance due to more uniform expansion and a tighter fit between tube and fin.

Variable fin pitch is used to delay frost formation on the filn's surface. Longer frosting interval. Easy access and cleaning.

mechanically, which improves heat exchange performance due to more uniform expansion and a tighter fit between tube and fin.

Variable fin pitch is used to delay frost formation on the filn's surface. Longer frosting interval. Easy access and cleaning.

Intelligent Control System

PLC touch screen, friendly interface, easy operation. Real-time display of equipment running status, the temperature of each area, and fault alarm. Preset freezing programs tailored for different products. Optional remote troubleshooting module.

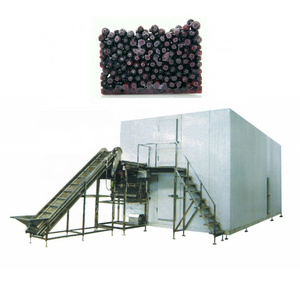

We just finished three tunnel IQF freezer project for a fried chicken plant in the United States. The project includes three

double spiral freezers. The spiral freezers have included the sequential defrosting, which have 4 separate coils isolated to each other. While one coil is under defrosting, the other three coils continue to be in freezing mode. It allows the up to 96 hours continuous production before stop the freezer for a thorough cleaning and defrosting. The CIP(system) is also fitted to automatically clean the freezer. It minimize the labor for cleaning, and keep the freezer in highest hygienic condition.

double spiral freezers. The spiral freezers have included the sequential defrosting, which have 4 separate coils isolated to each other. While one coil is under defrosting, the other three coils continue to be in freezing mode. It allows the up to 96 hours continuous production before stop the freezer for a thorough cleaning and defrosting. The CIP(system) is also fitted to automatically clean the freezer. It minimize the labor for cleaning, and keep the freezer in highest hygienic condition.

In the beginning of 2022, Square Technology Group delivered a spiral hardening freezer to NIF Pvt. Ltd. with the brand name of ice cream of NAMASTE INDIA. Our Team of Kap Cones Pvt. Ltd. installed the hardening tunnel in a professional manner with full technical support from Square Technology Group, and started up the hardening tunnel successfully. The full load running of the spiral hardener doubled NIF’s production capacity for its healthy, tasty and quality ice cream.

In April and May 2021, despite the Covid-19, Square Technology’ s technicians work together with Pakistan local team to

successfully installed a double spiral freezer for ice cream hardening in one of the renowned ice cream maker Hico Ice Cream in Lahore. It is a good example of the collaboration of the people of the two friendly countries. All the best to everyone who has contributed.

successfully installed a double spiral freezer for ice cream hardening in one of the renowned ice cream maker Hico Ice Cream in Lahore. It is a good example of the collaboration of the people of the two friendly countries. All the best to everyone who has contributed.

Square Technology Group Co. Ltd is a listed company in Shanghai-stock Exchange. The company has been manufacturing freezing systems for over 30 years and is the largest industrial freezer manufacturer in the China.

Our manufacturing facility is located in Nantong, China, with some 1300 employees and 64 hectares’ land. We serve a wide range of food processing industries and can draw from our extensive experience to provide our customers the best value and ensure maximum profitability.

The product line includes spiral freezer, plate freezer, tunnel IQF, refrigeration system, cold cooler, insulated panel, cooler,oven, ice machine, etc.

Our products have been exported to over 80 countries covering various applications, including seafood, protein, bakery, vegetable, fruits, etc. Square dedicate to deliver the superior quality freezing equipment to our client.

Our manufacturing facility is located in Nantong, China, with some 1300 employees and 64 hectares’ land. We serve a wide range of food processing industries and can draw from our extensive experience to provide our customers the best value and ensure maximum profitability.

The product line includes spiral freezer, plate freezer, tunnel IQF, refrigeration system, cold cooler, insulated panel, cooler,oven, ice machine, etc.

Our products have been exported to over 80 countries covering various applications, including seafood, protein, bakery, vegetable, fruits, etc. Square dedicate to deliver the superior quality freezing equipment to our client.

Hot Searches