- Product Details

- {{item.text}}

Quick Details

-

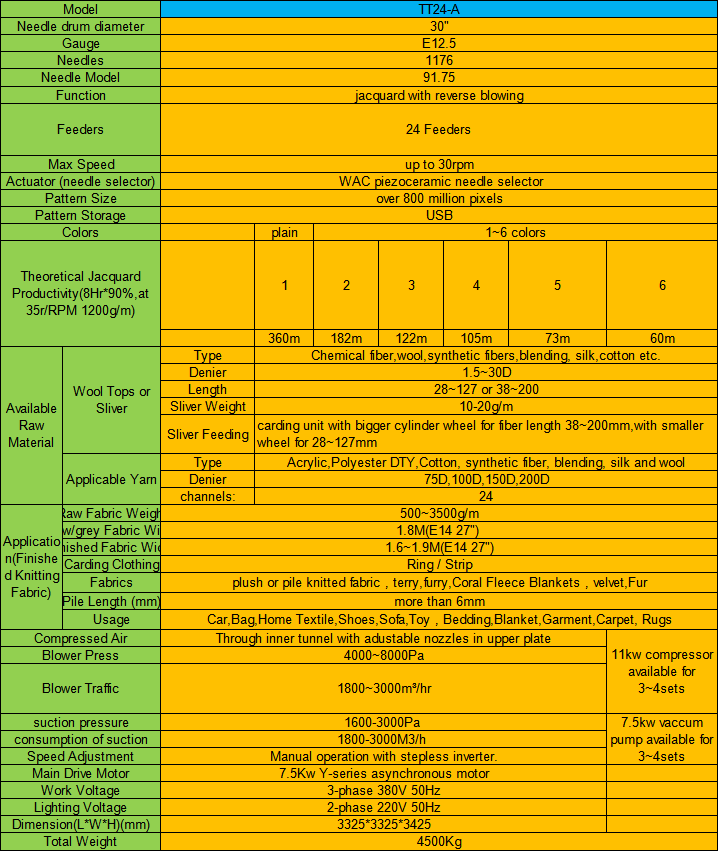

Knitting Method:

-

Single

-

Computerized:

-

Yes

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PYZZ

-

Model Number:

-

TT24-A

-

Power:

-

7.5kw

-

Weight:

-

4 tons

-

Dimension(L*W*H):

-

2100*2300*3400

-

Application:

-

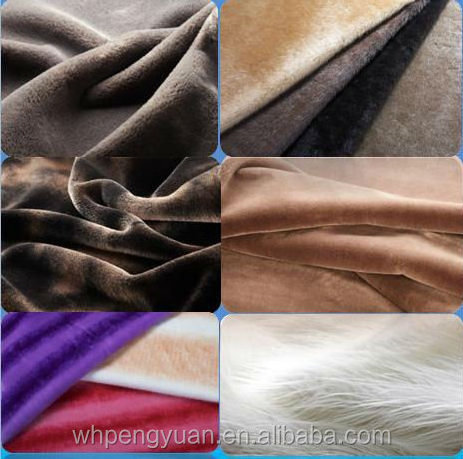

fake fur, wollen fabric

-

Certificate:

-

CE ISO

-

Function:

-

sliver knitting

-

Needles:

-

91.75

-

Gauge:

-

12.5g

-

needle Nos:

-

1176

-

Main power:

-

7.5kw

-

Cylinder:

-

30"

-

Feeder:

-

24F

-

Software:

-

Pattern design system

Quick Details

-

Type:

-

Circular

-

Production Capacity:

-

HIGH

-

Knitting Style:

-

Other

-

Knitting Method:

-

Single

-

Computerized:

-

Yes

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PYZZ

-

Model Number:

-

TT24-A

-

Power:

-

7.5kw

-

Weight:

-

4 tons

-

Dimension(L*W*H):

-

2100*2300*3400

-

Application:

-

fake fur, wollen fabric

-

Certificate:

-

CE ISO

-

Function:

-

sliver knitting

-

Needles:

-

91.75

-

Gauge:

-

12.5g

-

needle Nos:

-

1176

-

Main power:

-

7.5kw

-

Cylinder:

-

30"

-

Feeder:

-

24F

-

Software:

-

Pattern design system

Product Application

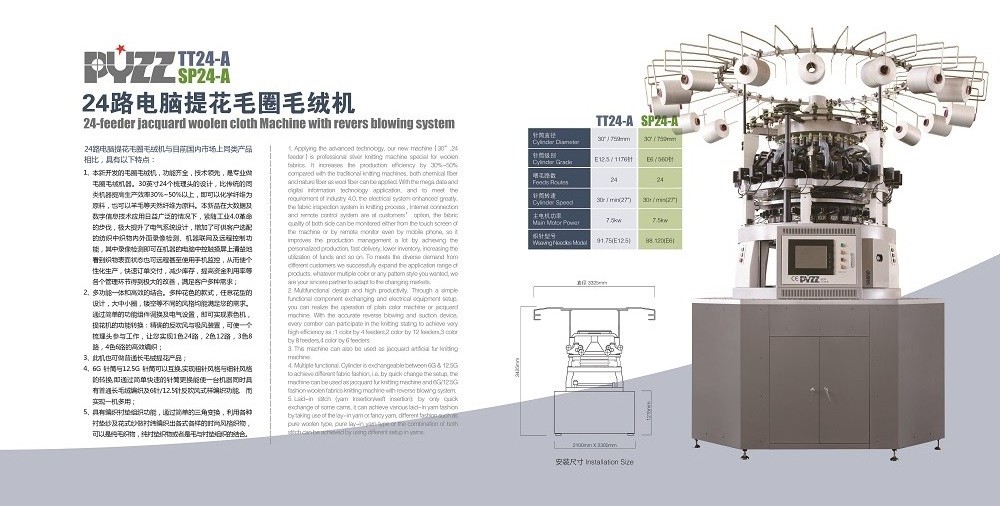

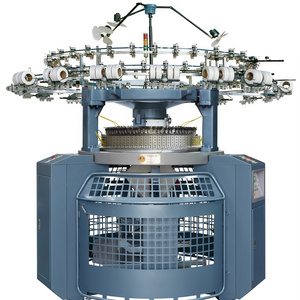

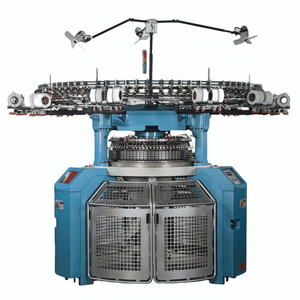

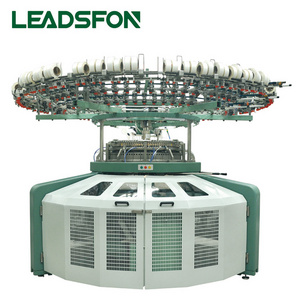

Jacquard Dual-function Artificial Fur and Woolen Fabric Knitting Machine with Reverse Blowing system

1.Applying the advanced technology, our new machine(30” ,24 feeder)is professional sliver knitting machine special for woolen fabrics. It increases the production efficiency by 30%~50% compared with the traditional knitting machines, both chemical fiber and nature fiber as wool fiber can be applied. With the mega data and digital information technology application, and to meet the requirement of industry 4.0, the electrical system enhanced greatly, the fabric inspection system in knitting process , Internet connection and remote control system are at customers’ option, the fabric quality of both side can be monitored either from the touch screen of the machine or by remote monitor even by mobile phone, so it improves the production management a lot by achieving the personalized production, fast delivery, lower inventory, increasing the utilization of funds and so on. To meets the diverse demand from different customers we successfully expand the application range of products, whatever multiple color or any pattern style you wanted, we are your sincere partner to adapt to the changing markets.

2.Multifunctional design and high productivity. Through a simple functional component exchanging and electrical equipment setup, you can realize the operation of plain color machine or jacquard machine. With the accurate reverse blowing and suction device, every comber can participate in the knitting stating to achieve very high efficiency as :1 color by 4 feeders,2 color by 12 feeders,3 color by 8 feeders,4 color by 6 feeders

3.This machine can also be used as jacquard artificial fur knitting machine.

4.Multiple functional. Cylinder is exchangeable between 6G & 12.5G to achieve different fabric fashion, i.e. by quick change the setup, the machine can be used as jacquard fur knitting machine and 6G/12.5G fashion woolen fabrics knitting machine with reverse blowing system.

5.Laid-in stitch (yarn Insertion/weft insertion): by only quick exchange of some cams, it can achieve various laid-in yarn fashion by taking use of the lay-in yarn or fancy yarn, different fashion such as pure woolen type, pure lay-in yarn type or the combination of both stitch can be achieved by using different setup in yarns.

Machine Parts

Name: Electric magnetic clutch

ensure stable fabric pinching strength and avoid over pulling to damage the fabric.

Needle selection actuator system

Stable needle selection to ensure high jacquard knitting quality.

Double layer sinker applied

with double layer sinker and cam combination, heavy duty high density high GSM fabrics can easy knitted without trouble.

computerized control system with windows system

it is very easy to change the pattern and machine operation due to industrial quality level touch LCD screen applied .

overseas after-sale service available at request of customers.

for first time installation and testing at customers' factory all related cost by user.