- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 220V/380V

-

Power:

-

28KW

-

Dimension(L*W*H):

-

3740x2150x3140

-

Weight (KG):

-

80000

-

Material:

-

Iron

-

After-sales Service Provided:

-

Overseas service center available

-

Color:

-

red & white

-

Application:

-

molding

-

Name:

-

Automatic Horizontal Parting flaskless molding machine

-

Function:

-

molding

-

Type:

-

Fully Automatic

-

Weight:

-

7.5-15T

Quick Details

-

Place of Origin:

-

Anhui, China

-

Machine Type:

-

molding machine

-

Brand Name:

-

xin ning

-

Voltage:

-

380V, 220V/380V

-

Power:

-

28KW

-

Dimension(L*W*H):

-

3740x2150x3140

-

Weight (KG):

-

80000

-

Material:

-

Iron

-

After-sales Service Provided:

-

Overseas service center available

-

Color:

-

red & white

-

Application:

-

molding

-

Name:

-

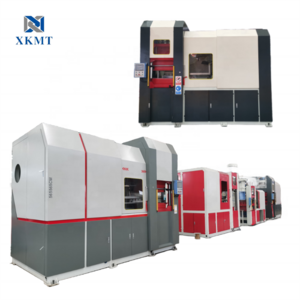

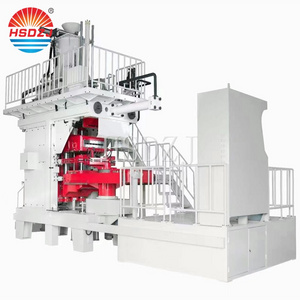

Automatic Horizontal Parting flaskless molding machine

-

Function:

-

molding

-

Type:

-

Fully Automatic

-

Weight:

-

7.5-15T

Production information:

XN-SW

Series Green Sand Automatic Foundry Casting Horizontal Parting Flaskless Molding Machine -This is an automatic molding machine to replace traditional manual hand molding method. It has compact structure and high safety performance, easy to operate, cover small floor space and make low noise.

Application:

Widely used in castings, machinery parts, auto and motorcycle parts, valves, bearings, cylinder head, flywheel housing and brake caliper, but also pipe fitting, shaft and cover, like T joint, elbow and clampetc .

More competitive for those products require inner sand core.

Main parameter & spec.:

|

Model |

XN-SW-55x45 |

XN-SW-60x50 |

XN-SW-6 5x55 |

XN-SW-71x61 |

XN-SW-71x61 HY |

|

Size of Sand Mold (mm×mm) |

550*450mm |

600*500 mm |

650*550mm |

710*610mm |

710*610mm |

|

Sand Mold Thickness (mm) |

120-180mm |

120-220 mm |

120-220mm |

120-220mm |

120-250 |

|

Mold way |

Injection and Compaction |

||||

|

Moulding speed (Sec/mold) |

32(Without the time of

|

36(Without the time of

|

38(Without the time of

|

38(Without the time of

|

45(Without the time of

|

|

Compaction pressure |

0.6Mpa |

0.7Mpa |

0.7Mpa |

0.7Mpa |

0.7Mpa |

|

Drive mode |

Hydraumatic-pneumatic |

||||

|

Air consumption |

1.1m 3 (Normal/mold) |

1.2m 3 (Normal/mold) |

1.2m 3 (Normal/mold) |

1.3m 3 (Normal/mold) |

1.3m 3 (Normal/mold) |

|

Power supply |

AC220-380V (Operation DC24V) |

||||

|

Sand mold weight |

85kg |

130kg |

150kg |

210kg |

320kg |

|

Motor power |

24KW |

28KW |

28KW |

36KW |

36KW |

|

Max Productivity |

120 molds/h (Excluding core setting time) |

100-120 molds/h (Excluding core setting time) |

100-120 molds/h (Excluding core setting time) |

100-120 molds/h (Excluding core setting time) |

90-100 molds/h (Excluding core setting time) |

Advantages:

1) Over 12 years experience in casting equipment.

2) First and most accepted China brand.

3) Most competitive price and quality.

4) Short delivery time.

5) Instant aftersale service on line.

6) Import and Export License.

7) OEM.

Sale & after-sale service:

Warranty 1 year free.

Lifetime maintenance.

Afersale service: instant service, by on line chatting, or by phone, or by remote services or other way by negotiation.

Automatic Horizontal Parting Flaskless Molding Casting Machine operational Site:

Packing:

About Company:

Xinning Group covers an area of more than 40 acres and has a production plant of more than 50,000 square meters. With more than 20 years of experience and product development accumulation, Xinning Group has transformed from wear-resistant casting production to professional research and development. A high-end foundry equipment enterprise integrating manufacturing and sales has become a high-tech enterprise focusing on independent research and development of foundry equipment in the foundry industry. After 20 years Xinning Group has set up Xinning R&D center in Hangzhou and Xinning design department in Ningguo at headquarter. Based on more than 20 years of practical experience, the company has strong manufacturing innovation ability and rapid response mechanism, and continuously creates value for customers' transformation and upgrading. Xinning Group strictly comply the international manufacturing standards such as CE and ISO9001 standard and strict control of each production process, scientific quality control process, and perfect after-sales service system to provide safety guarantee for customers' use. According to the customer's product process and site, Xinning has customized the production line equipment to meet the customer's requirements. At the same time, it provides overall planning and design, process technical support and operator training for foundry enterprises, and provides one-stop service. Xinning group pursues the concept of excellence in the development policy, focusing on the R&D innovation, manufacturing and sales of casting equipment for 20 years.

Awards and certifications:

Our Exhibition:

Client Gallery:

1. Are you a manufacturer?

Yes, we are a manufacturer as well as a supplier of various types of steam turbines.

2.What about the product quality?

We have testing and quality control department to ensure the quality of the products to meet national and international standards in the steam turbine industry.

3.What about the price?

We only offer a reasonable price instead of high price. Different quality and at a different price.

4. What about after sales services?

We provide after sales services based on customer demand. we provide installation and maintenance assistance abroad as we have customers around the globe. for more detail see above "Our Services".

5. What about Custom manufacturing?

Yes, we do custom manufacturing as well based on customer requirement.