Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Variable

-

Power (kW):

-

300KW

-

Weight:

-

5

-

Screw Speed (rpm):

-

1 - 100 rpm

-

Name:

-

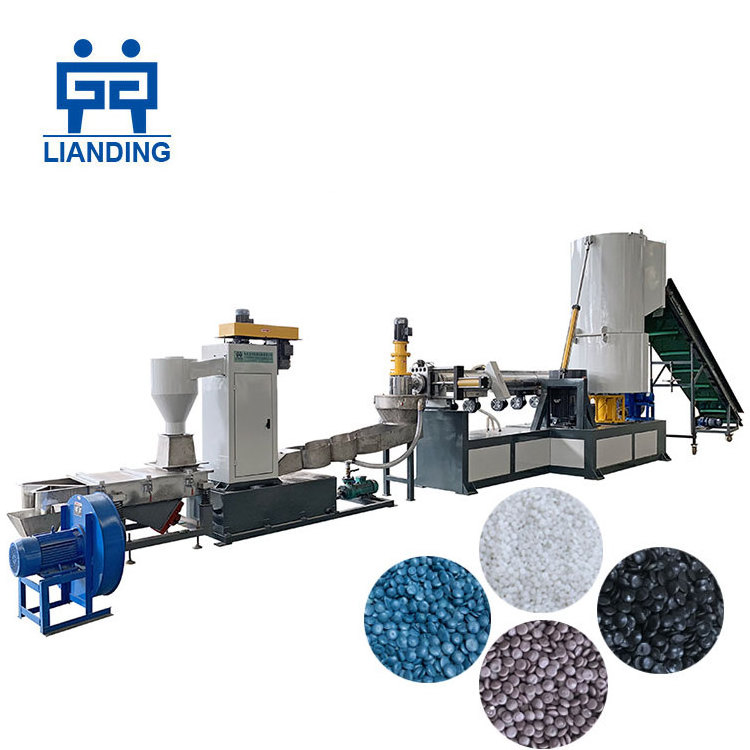

waste plastic granules making machine

-

Machine Material:

-

Stainless Steel

-

cutting ways:

-

water-ring cutting

-

Function:

-

pp pe pelletizing granulating

-

Raw material:

-

crushed PP PE film or blocks

-

Final product:

-

PP PE Granules

-

Application:

-

Granules Production

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

SCREW MATERIAL:

-

38CrMoAl

Quick Details

-

Output (kg/h):

-

100 - 800 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Lianding

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Variable

-

Power (kW):

-

300KW

-

Weight:

-

5

-

Screw Speed (rpm):

-

1 - 100 rpm

-

Name:

-

waste plastic granules making machine

-

Machine Material:

-

Stainless Steel

-

cutting ways:

-

water-ring cutting

-

Function:

-

pp pe pelletizing granulating

-

Raw material:

-

crushed PP PE film or blocks

-

Final product:

-

PP PE Granules

-

Application:

-

Granules Production

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

SCREW MATERIAL:

-

38CrMoAl

Customized pp pe pelletizing line plastic recycling granulating machine waste plastic granules making machine

Features:

1.

Very strong and long life

: Screw and barrel are made of 38CrMoAlA, inlet mouth treated with special alloy:

2.

Easy operation

: it has automatic constant temperature control and stable performance. After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver.

3.

Low cost in using after redesign

: now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy!

4.

High output, long operating life and lower noise

: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

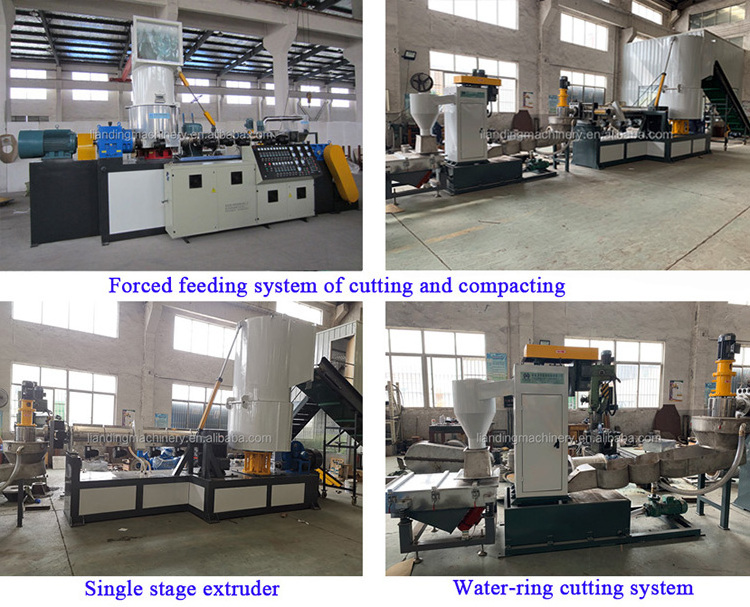

Configuration:

| No. | Name | Specification | Amount |

| 1 | Belt conveyor | DS-60 | 1set |

| 2 | Pelletizing system |

single stage extruder/ double stage extruder |

1set |

| 3 | Water-ring cutting machine | 1set | |

| 4 | Dewatering machine | 1set | |

| 5 | Vibrating screen | 1set | |

| 6 | Air conveyor system | 1set | |

| 7 | Storage | 1set |

Pelletizing types:

1. Single/double stage water-ring cutting pelletizing line

a. Fast hydraulic screen changing system

b. High efficiency water-ring cutting(Die-face hot cutting system)

c. Stainless steel water-ring, water cooling tank, dewatering machine, silo.

2. Compacting water-ring cutting pelletizing line

a. Forced feeding system of cutting and compacting

b. Fast hydraulic screen changing system

c. High efficiency water-ring cutting(Die-face hot cutting system)

More pictures:

Techincal Parameters

| PP PE PELLETIZING MACHINE | ||||||

| Model | SJ-65 | SJ-80 | SJ-100 | SJ-120 | SJ-150 | SJ-200 |

| Screw diameter | 65mm | 80mm | 100mm | 120mm | 150mm | 200mm |

| L/D | 28-30mm | 28-30mm | 28-30mm | 28-30mm | 28-30mm | 28-30mm |

| Capacity | 60-80kg/h | 80-100kg/h | 150-200kg/h | 300-350kg/h | 400-450kg/h | 500-550kg/h |