- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

HC-DCF-OEM

-

Product Name:

-

Custom Gasket

-

Color:

-

Black or OEM

-

Size:

-

OEM

-

Certificate:

-

ISO13485

-

Shape:

-

OEM

-

Usage:

-

Medical products or more

-

Packaging:

-

Inner polybag, outer by carton

-

MOQ:

-

Low MOQ

-

Sample:

-

Available

Quick Details

-

Material:

-

EVA, PU, PP, PE EVA PU PP

-

Type:

-

Foam

-

Place of Origin:

-

GUA

-

Brand Name:

-

OEM

-

Model Number:

-

HC-DCF-OEM

-

Product Name:

-

Custom Gasket

-

Color:

-

Black or OEM

-

Size:

-

OEM

-

Certificate:

-

ISO13485

-

Shape:

-

OEM

-

Usage:

-

Medical products or more

-

Packaging:

-

Inner polybag, outer by carton

-

MOQ:

-

Low MOQ

-

Sample:

-

Available

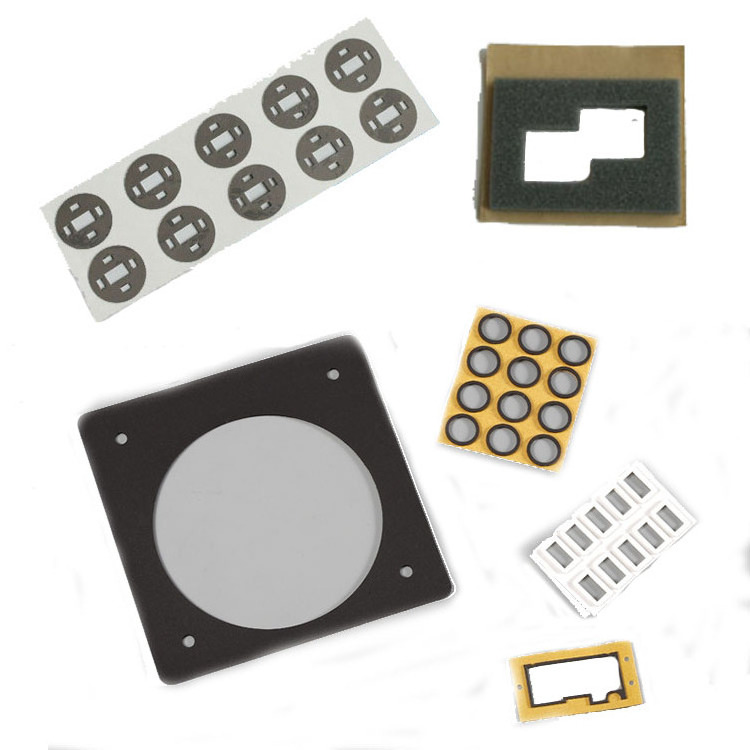

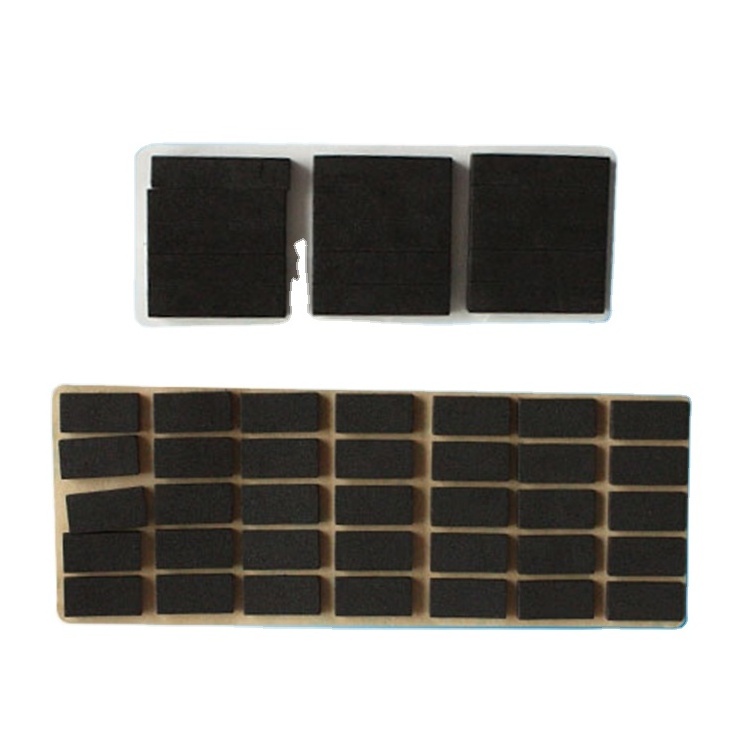

Heat Resistant Foam Padding 1mm 2mm 3mm Rotary Die Cut Closed Cell Polyurethane Foam Insulation Sheets

Product Description

| Company Name | Hochuen Medical Technology Co., Ltd. |

| Business Type | Manufacturer/OEM Factory |

| Manufacture Capabilities | Injection molding, microfluidic devices, adhesive, die cutting, lamination, LSR, bonding (including laser welding, ultrasonic welding, heat staking, etc.), dry reagent handling, reagent blister packing, wet lab process, PCR QC test, CNC precision machining, laser machining, rapid prototyping, label printing, softgood manufacturing, sterilization/packaging,etc. |

| Die Cut Materials | ABS, PC, PP, PS, POM, PMMA, PE, PA, HIPS, TPU, PE, BOPP, EPDM, Liquid Silicone Rubber (LSR), foams, tapes, films, paper, etc. |

| Colors Available | Black, white, clear, red, blue, or according to customer's requirements. |

| File Format | Solidworks, DWG, PDF, AI, STP/STEP, etc. |

| Quality Management | ISO9001, ISO14001, ISO13485(ALL THE MEDICAL PRODUCTS MEET F.D.A STANDARDS), ISO45001 |

| Other services offered | Printing, die cutting, CNC machining, assemblying and packaging, etc. |

| Payment Method | T/T or online transactions(by trade assurance) for option |

| Products Applications | Medical instrument parts and medical disposables, consumer electronics, sports, beauty and personal care products, baby's products, biosensors for DNA analysis or chemical research, Medical foams/tapes or thermal insulation pad for other biometrics,small parts for automobile, aviation and aerospace equipments, etc. |

| Prototyping | Drawings and quantities will be needed for a detailed quotation. Free Sample will be offered for approval after PO for molding is confirmed. |

Packaging & Shipping

For packing, we can use inner plastic bags with foam, and outer cardboard boxes or wooden case with great protect to avoid any vibration. We can also use customized packages according to customer's requirements.

Factory Display

Exhibition

FAQ

1. What kind of printing you can do?

We have silkscreen printing, pad printing, digital printing, UV printing, off-set printing, laser printing. (Including automatic printing, semi-auto printing, etc.)

2. How do you cut the parts?

We have laser cutting, die cutting, CNC machining and stamping.

3. What Certificate do you have?

We have certified with ISO 9001, ISO 14001, ISO 45001, and ISO 13485.

4. What tons of injection molding machine do you have?

From 50 tons to 450 tons, we mainly focus on consumable medical device, LSR (liquid silicone rubber) also available, and we do mold in house.

5. How do you assemble the parts?

Typically we have PSA bonding, laser welding, ultrosonic welding, diffusion bonding, etc.

6. Are you available only prototyping or from prototyping to manufacturing?

We are an OEM manufacturer, and provide one stop service from prototyping to mass production.

All of our products are customized.

Hot Searches