- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

ZCQ

-

Model Number:

-

Clear Quartz Plate

-

Product Name:

-

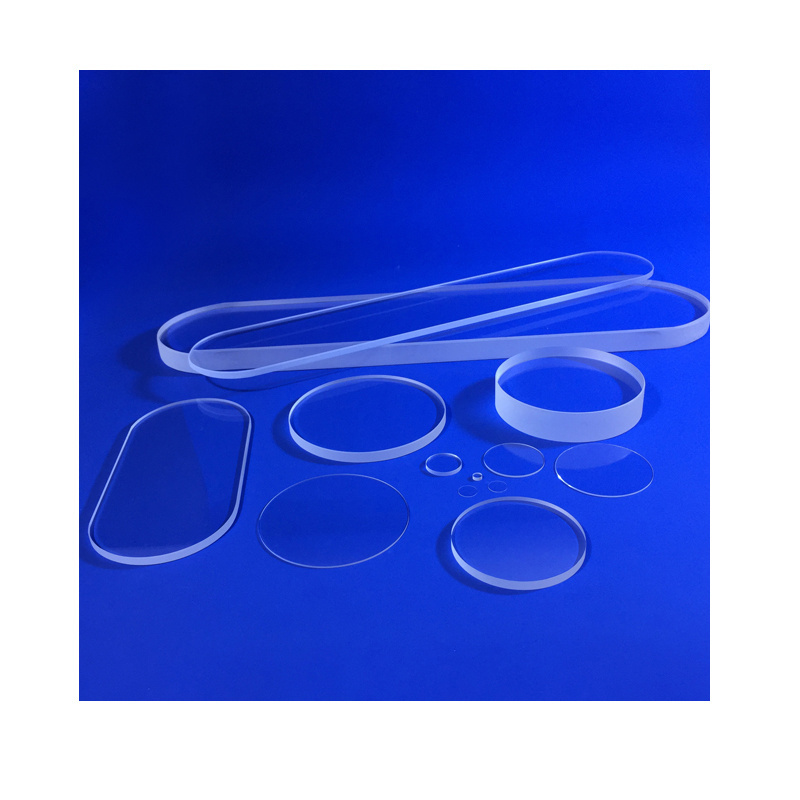

Quartz sheet quartz glass sheet quartz crystal sheet

-

Color:

-

Clear

-

Surface Treatment:

-

Polished

-

Surface Finish:

-

80/50 64/40 20/10

-

Applications:

-

Optical Space Flight High Temperature Equipment

-

Work temperature:

-

1000 degree

-

Density:

-

2.2g/cm2

-

Export Market:

-

America,Japan,South Korea, Canada, Malaysia,England,Russia,Thailand

-

Material:

-

99.99% Pure Quartz

-

Edge:

-

Grind

Quick Details

-

Type:

-

Clear Quartz Plate

-

Application:

-

Semicondutor, Optics, Electronics

-

Thickness:

-

2mm

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

ZCQ

-

Model Number:

-

Clear Quartz Plate

-

Product Name:

-

Quartz sheet quartz glass sheet quartz crystal sheet

-

Color:

-

Clear

-

Surface Treatment:

-

Polished

-

Surface Finish:

-

80/50 64/40 20/10

-

Applications:

-

Optical Space Flight High Temperature Equipment

-

Work temperature:

-

1000 degree

-

Density:

-

2.2g/cm2

-

Export Market:

-

America,Japan,South Korea, Canada, Malaysia,England,Russia,Thailand

-

Material:

-

99.99% Pure Quartz

-

Edge:

-

Grind

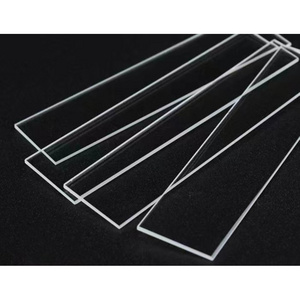

Quartz sheet quartz glass sheet quartz crystal sheet

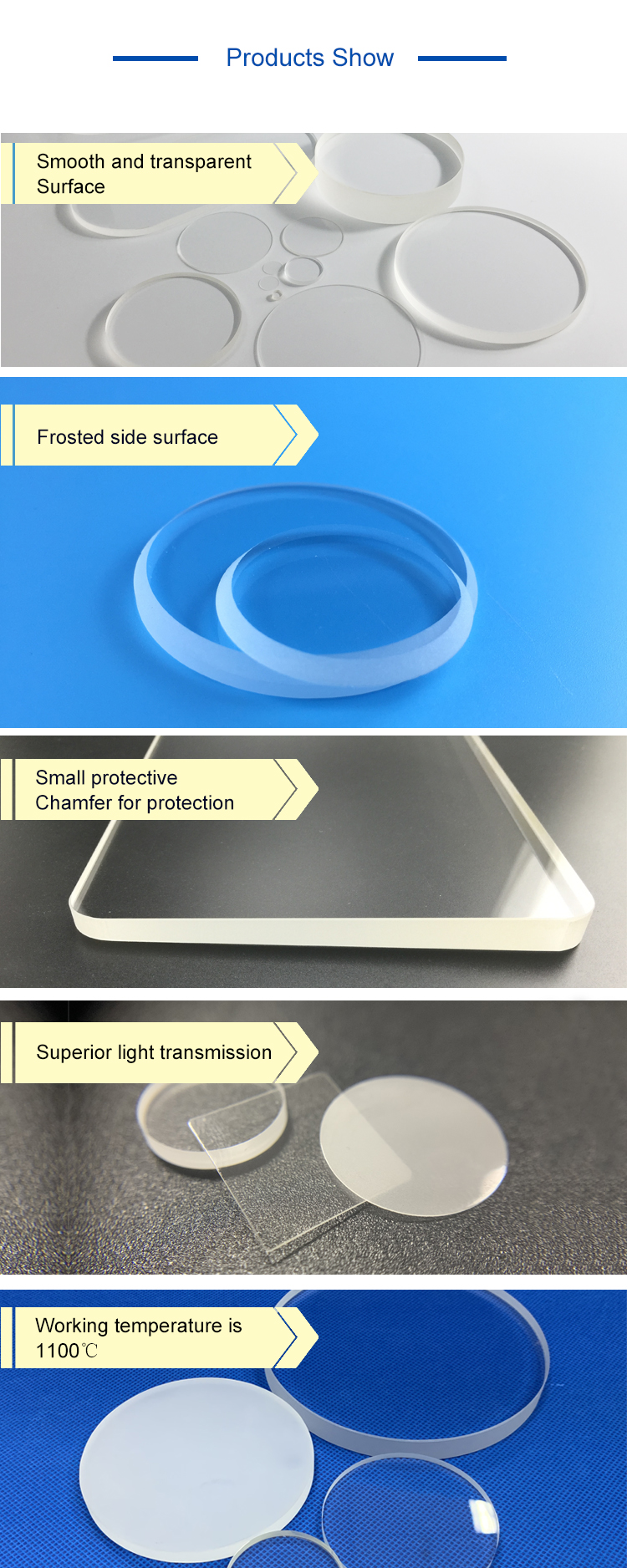

Product Introductions

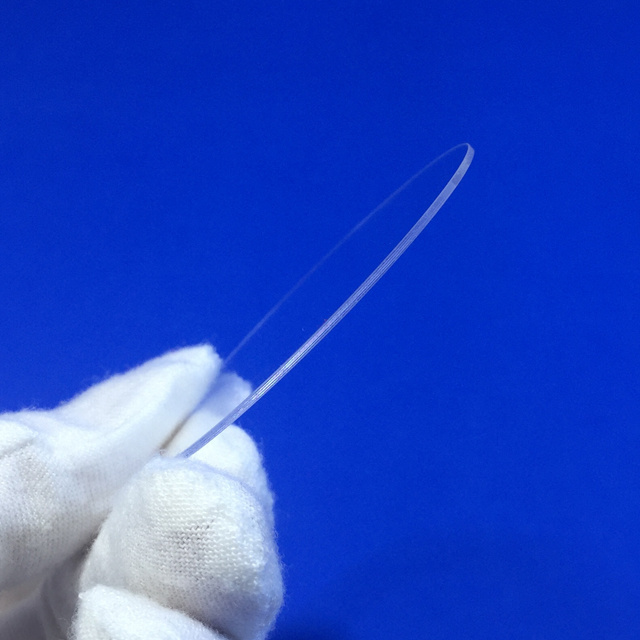

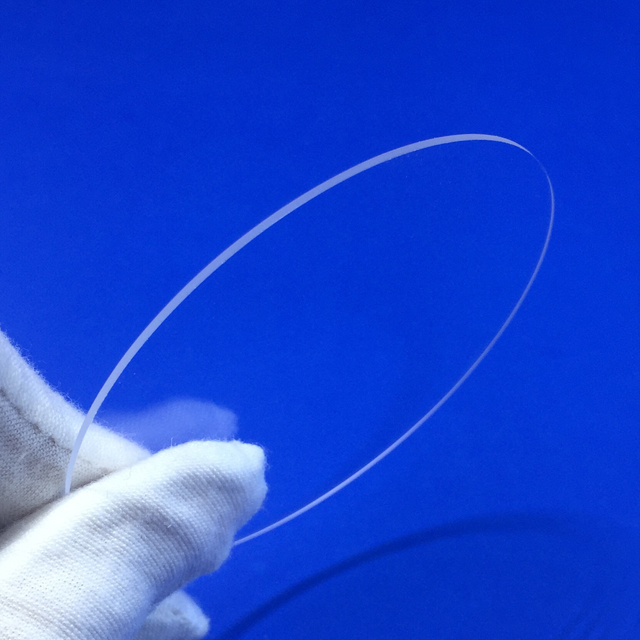

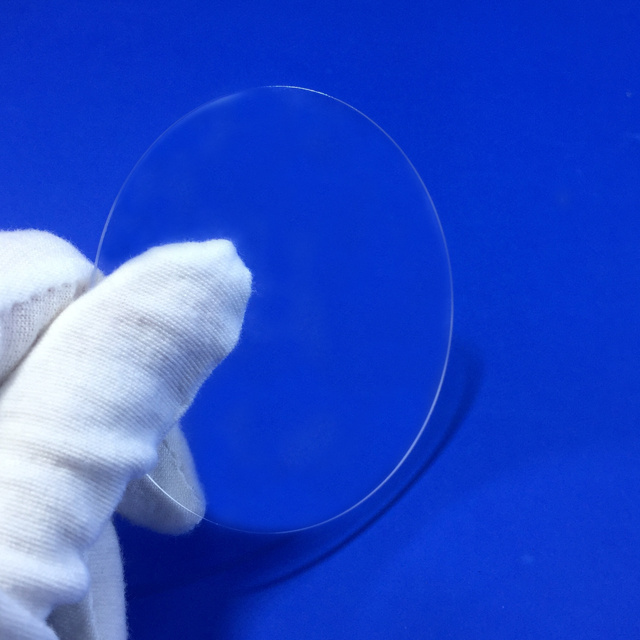

Size:

75*75*28*2mm

material: fused quartz/ fused silica

Appearance : clear, both sides polished,

ground edges /protective bevel

free of bubble or scratch or airline

Regular temperature : 1000 °C

Resistant of strong chemistry like acid or alkali

Typical Application:

Optical Windows are applied to isolate different physical environments meanwhile

allowing light to drill through.

When selecting windows, you should consider these factors, materials, transmission,

scattering, wavefront distortion,parallelism and resistance to certain environment.

ZCQ offers a wide range of different materials and different degree of precision windows. Materials are UV Fused Silica, BK7, B270, CaF2, MgF2, etc.

Physical Parameter of ZCQ Quartz Products:

|

Parameter |

Standard |

Precision |

U ltra precision |

|

Dimensional Tolerance |

±0.1 |

±0.1 |

±0.1 |

|

Clear Aperture |

>80% to >90% |

>80% to >90% |

>80% to >90% |

|

Surface Quality |

60-40 |

40-20 |

20-10 to 10-5 |

|

Parallelism |

1 arc min |

30 arc seconds |

1 arc min |

|

Wavefront Distortion |

1 λper 25mm |

λ/4 |

λ/10 |

|

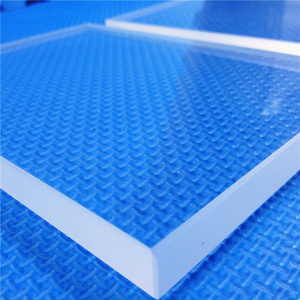

Protective Bevel |

<0.25x45 deg |

<0.25x45 deg |

<0.25x45 deg |

|

Coating |

optional |

||

Techn i cal Information :

|

Density |

2.203 g/cm3 |

|

Hardness |

7 (Modified Scale); 5.36.5 (Mohs Scale) |

|

Tensile strength |

48.3 MPa |

|

Compressive strength |

>1.1 GPa |

|

Bulk modulus |

~37 GPa |

|

Rigidity modulus |

31 GPa |

|

Young's modulus |

71.7 GPa |

|

Poisson's ratio |

0.16 |

|

Coefficient of thermal expansion |

5.5×10-7 cm/(cmK) ( from 20°C to 320°C) |

|

Thermal conductivity |

1.3 W/(mK) |

|

Heat capacity |

45.3 J/mol |

|

Softening point |

1730°C |

|

Annealing point |

1180°C |

|

Strain point |

1075°C |

|

Electrical resistivity |

>1018 Ωm |

|

Dielectric constant |

3.75 at 20°C 1 MHz |

|

Dielectric loss factor |

less than 0.0004 at 20°C 1 MHz |

|

Index of refraction at 587.6 nm (nd) |

1.4585 |

Applications:

l Electro Optics

l Pressure Windows

l Inspection Windows

l Sensor and Measurement Systems

l Analytical Instruments

l Scientific Research