- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

450kg, 450kg

-

Size:

-

2350*800*1430mm, 2350*800*1430mm

-

Power:

-

0.92KW

-

Weight (KG):

-

450 kg

-

Product name:

-

Industrial waste dewatering equipment compact screw type filter press

-

Application:

-

Sludge dewatering

-

Color:

-

Customers Demands

-

Usage:

-

Environmental Protection

-

After-sales Service Provided:

-

12 month

-

Processing:

-

Pretreatment

-

Function:

-

Auto

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JLCDFP

-

Material:

-

stainless steel, SS304

-

Weight:

-

450kg, 450kg

-

Size:

-

2350*800*1430mm, 2350*800*1430mm

-

Power:

-

0.92KW

-

Weight (KG):

-

450 kg

-

Product name:

-

Industrial waste dewatering equipment compact screw type filter press

-

Application:

-

Sludge dewatering

-

Color:

-

Customers Demands

-

Usage:

-

Environmental Protection

-

After-sales Service Provided:

-

12 month

-

Processing:

-

Pretreatment

-

Function:

-

Auto

Product Application

Our company are always focusing on independent technology innovation of themselves. we have successfully developed the new generation of sludge dewatering technology - multi-plate screw press, a screw type sludge dehydrator that is much more advanced in very aspects than belt presses, centrifues, plate-and-frame filter presses, etc. It features clogging-free, wide range of applications, low energy consumption, simple operation & maintenance.

Industrial waste dewatering equipment compact screw type filter press

Main Parts: Sludge concentration & dewatering Body; Flocculation & Conditioning Tank; Integrate Automatic Control Cabinet; Filtrate Collection Tank

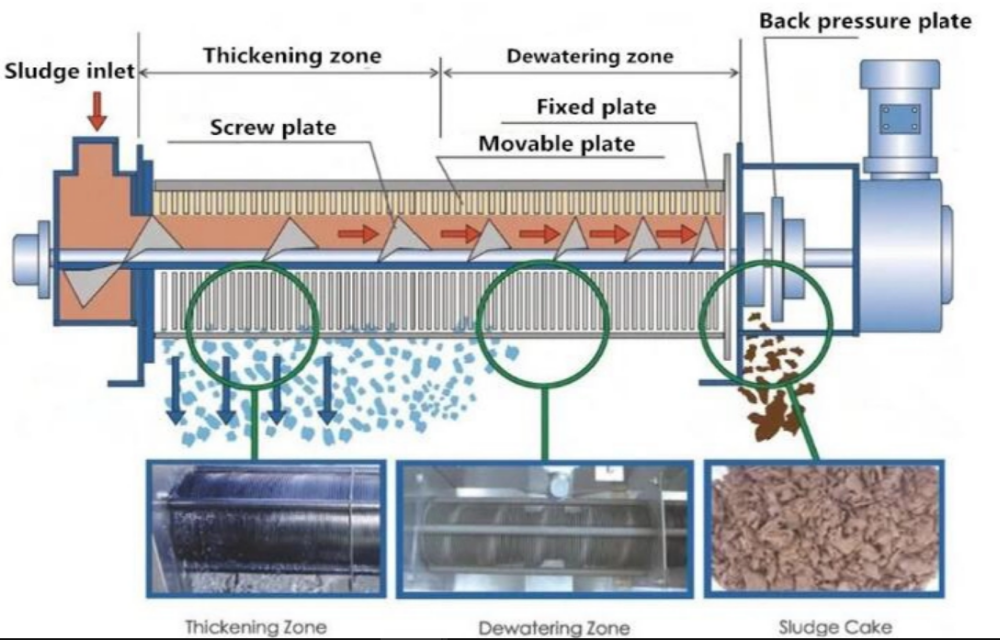

Working Principle:

Force-water concurrent; Thin-layer dewatering; Moderate press; Extension of the dewatering path

It has solved several technical problems of other similar sludge dewatering equipment including belt presses, centrifuge machines, plate-and-frame filter press have, which are frequent clogging, low concentration sludge / oil sludge treatment failure, high energy consumption and complicated operation etc

Thickening: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Dewatering: The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Self-cleaning: The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering equipment.

Product Feature:

Special pre-concentrating device, wide feed solids concentration: 2000mg/L-50000mg/L

The dewatering part of MSP consists of a thickening zone and a dewatering zone. In addition, a special pre-concentrating device is mounted inner the flocculation tank. Therefore, the wastewater with rather low solids content is not a problem to MSP. The applicable feed solids concentration can be as very wide as 2000mg/L-50000mg/L.

Since MSP can be used directly to concentrate and dewater the low-solid sludge from aeration tanks or secondary clarifiers, the users don't have to build a thickening tank or a storage tank any more while they have to when using other types of sludge dehydrators, especially the belt filter presses. Then significant civil engineering cost and floor area are saved.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Main Parts:

Sludge concentration & dewatering Body; Flocculation & Conditioning Tank; Integrate Automatic Control Cabinet; Filtrate Collection Tank

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

[A]You can provide us your water sources, water quality, flow rate and ground area (contact us for more details).

[A]TT and L/C are acceptable and TT will be more appreciated.30% deposit in advance and balance before loading.

[A] It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

[A]We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

[A]We use the world-famous paint, like SigmaCoatings,PainBow,etc. What's more, we paint strictly according to the standard process.

[A]Our machining technology includes laser/plasma cutting, automatic welding,CNC cutting and bending.

[Q] How to install after the equipments arriving destination?

[A] We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate