- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HZ

-

product name:

-

plastic mould

-

plastic raw material:

-

PE,PP,ABS,PC ,POM,PA6

-

Hardness:

-

32-50HRC

-

mould base:

-

LKM,HASCO,DEM,ECT

-

mould steel:

-

718,738,NAK

-

Runner:

-

hot,cold

-

size:

-

subject to product size

-

mould life:

-

500,000-1,000,000times

-

lead time:

-

25-40 working days

-

Machining:

-

CNC,EDM,Grinding,Wire-EDM,Milling,et

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

wingo

-

Model Number:

-

HZ

-

product name:

-

plastic mould

-

plastic raw material:

-

PE,PP,ABS,PC ,POM,PA6

-

Hardness:

-

32-50HRC

-

mould base:

-

LKM,HASCO,DEM,ECT

-

mould steel:

-

718,738,NAK

-

Runner:

-

hot,cold

-

size:

-

subject to product size

-

mould life:

-

500,000-1,000,000times

-

lead time:

-

25-40 working days

-

Machining:

-

CNC,EDM,Grinding,Wire-EDM,Milling,et

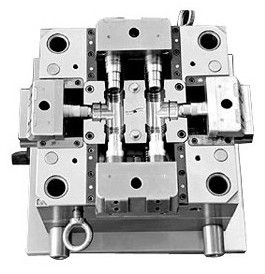

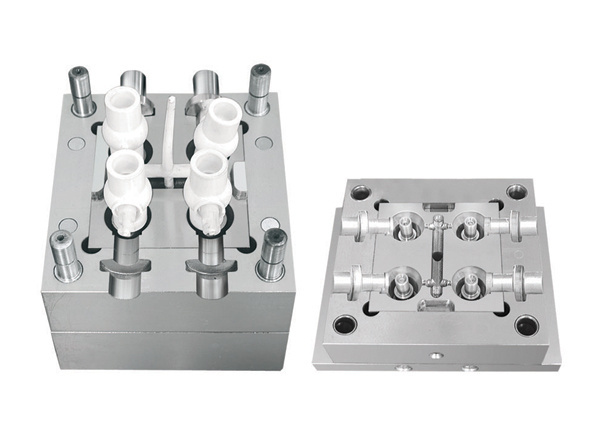

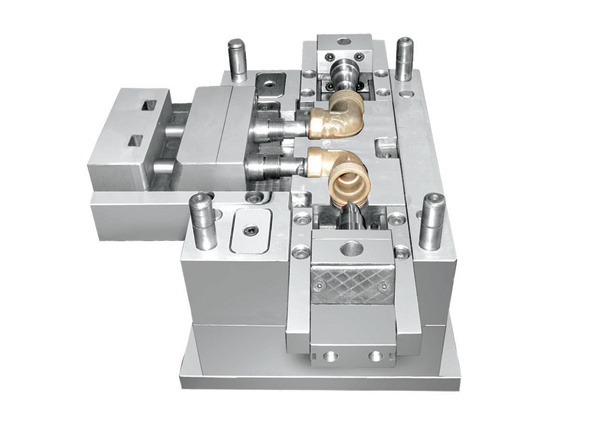

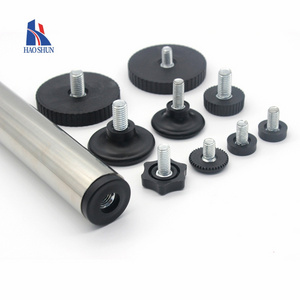

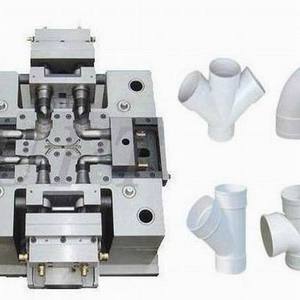

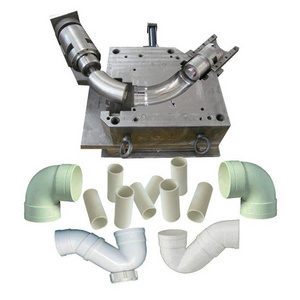

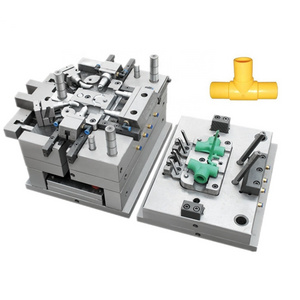

Plastic P roducts Specifications

1.High quality, competitive price

2. ISO9001/TS16949/ISO14001

3. high standard of workmanship

4. Customized

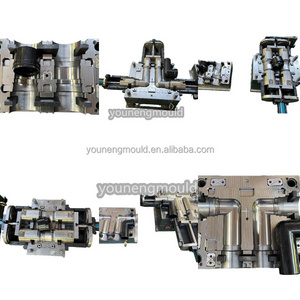

We have a high-level designers team and we adopt advanced machine. Company set up mould workshop and injecting workshop. Equiped advanced tool machining equipment , for example , CNC, electricity , line-incise, grinding, milling, lathe and so on.The essential info of mould .

Mould Information:

1.Material:45#,P20,718,2738, NAK80,S136 etc.

2. Standard Base :LKM,HASCO,DME

3.Treatment:pretreat and Nitriding

4.Cavity:Single or Multi

5.Runner:Cold or Hot

6.Mould life:above300,000 shots

7.Related Plastic Material:PP,PC,PS,PE,PVC,ABS,HDPE,LDPE ect.

Equipments:

1. CNC milling machine: 3

2. CNC engraving machine: 3

3. Slow wire cutting machine: 3

4. CNC high speed milling machine: 3

5. CNC deep hole drilling machine: 3

6. Linear cutting machine: 6

7. Drilling machine: 3

8. CNC EDM: 3

9. Throwing Knives: 5

The Company Flow Chart

|

1.Enquiry |

Our customers send drawing or 3D with detail information to us. |

|

↓ |

|

|

2. Quote |

According to the details,we make an offer. |

|

↓ |

|

|

3. Negotiation |

The material,delivery time,payment ,price and ect. |

|

↓ |

|

|

4.Place an order |

Contract Examing&Commenting. |

|

↓ |

|

|

5.Mold Design |

Mold Structure Drawing and Auditing. |

|

↓ |

|

|

6.Mold Make |

Before making,we send design to customer to approve. |

|

↓ |

|

|

7.Test Sample |

We send the test sample to customer until meet customers’requests |

|

↓ |

|

|

8.Delivery |

Delivery by sea or according to customers’ |

Our Advantages:

1.Good credit and service.

2. Competitive price based on excellent quality

3. On-time delivery.

4. Good quality management and good teamwork