- Product Details

- {{item.text}}

Quick Details

-

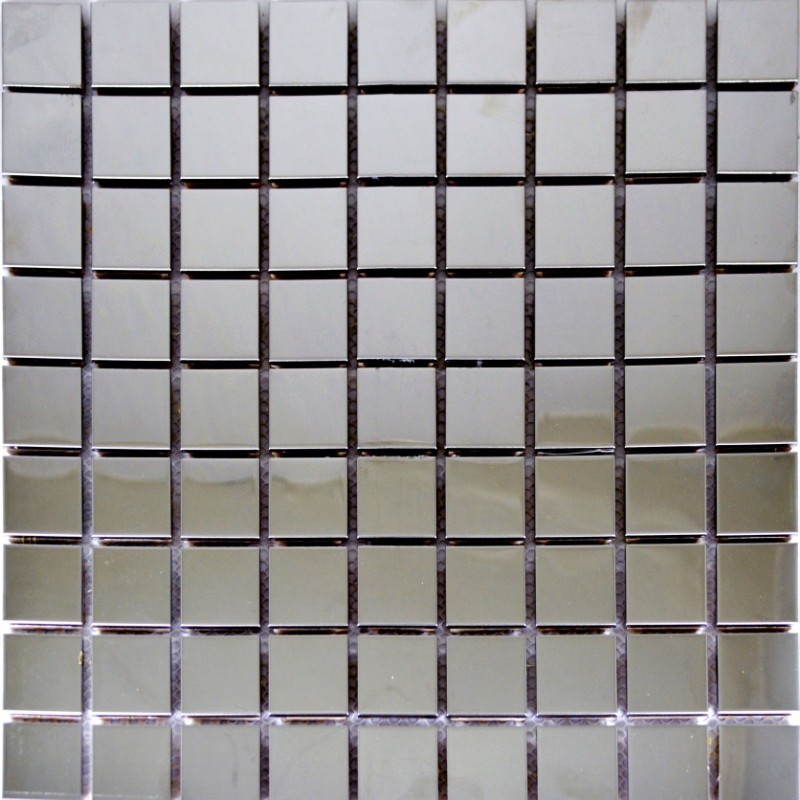

Shape:

-

Square

-

Size:

-

30 X 30MM or customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sarhang

-

Model Number:

-

SHS-SS010

-

Usage:

-

Wall and floor

-

Color:

-

Silver

-

Sheet size:

-

305x305mm

-

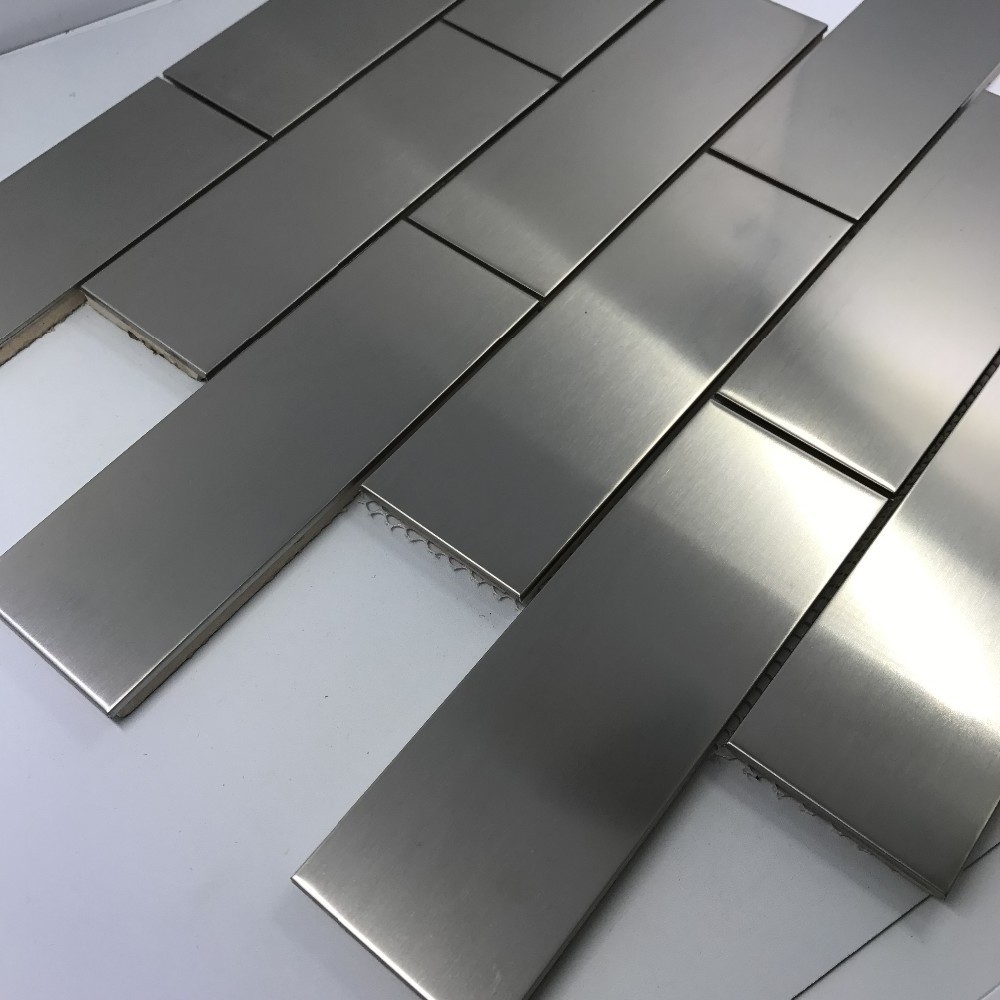

Surface finished:

-

Brushed or poliahed

-

Regular size:

-

Customized

-

Edge:

-

Mill Edge Slit Edge

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Villa,Hotel ,Home etc.

-

Design Style:

-

Modern

-

Shape:

-

Square

-

Size:

-

30 X 30MM or customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sarhang

-

Model Number:

-

SHS-SS010

-

Usage:

-

Wall and floor

-

Color:

-

Silver

-

Sheet size:

-

305x305mm

-

Surface finished:

-

Brushed or poliahed

-

Regular size:

-

Customized

-

Edge:

-

Mill Edge Slit Edge

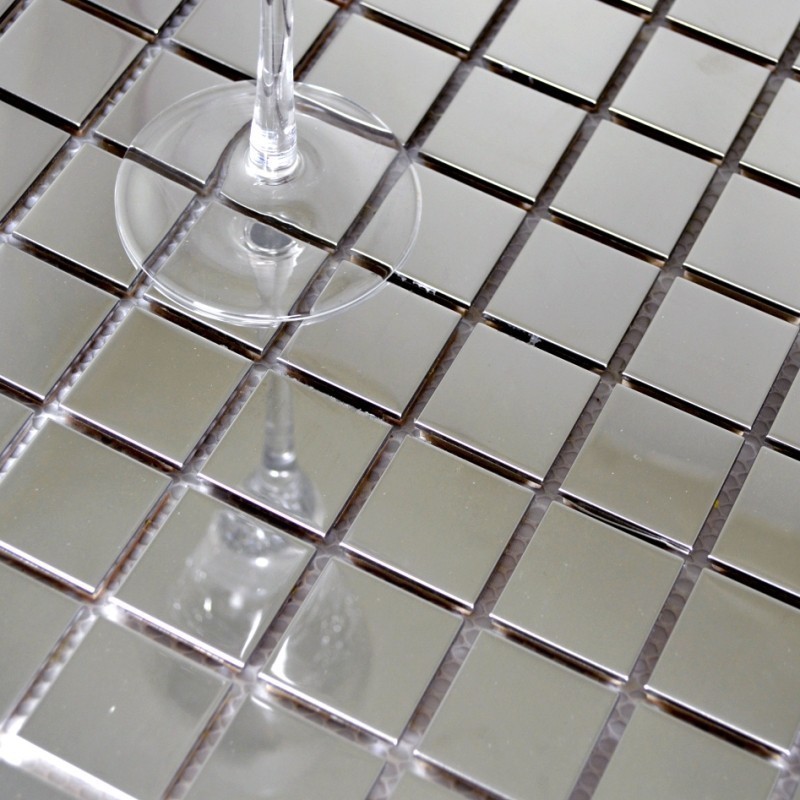

#304 STAINLESS STEEL mosaic are good for bathroom and kitchen decoration.

|

Product

|

Mosaic Tile

|

|

Material

|

304 Stainless Steel

|

|

Edge

|

Straight/Irregular

|

|

Toxin

|

Non

|

|

Radioaction

|

Non

|

|

Water Absorption

|

≤3.0%

|

|

Bending resistance

|

Resistant

|

|

Breaking resistance

|

Resistant

|

|

Hardness

|

High

|

|

Discolor

|

Non

|

|

Thermal shock resistance

|

Resistant

|

|

Easy Cleaning

|

Yes

|

|

Easy Installation

|

Yes

|

|

Mounted On

|

Fiber Mesh/Adhesives

|

1. Metal is non porous, grease, spills will not be absorbed into the tile.

2. Metal mosaic tiles don't stain and can last a long time.

3. They can provide plenty of options in style and color.

4. They can provide a lot of flexibility in pattern design.

5. They are easy to maintain; any dirty/greasy spots can be quickly wiped with a wet cloth.

6. Metal mosaic tiles is better for environment.

1. We suggest adopting professional binder and joint filler, and parts of our products adopt

neutral adhersives.

2. Use professional grey knife to scrap 2-3mm thick paste binder after cleaning the surface.

3. Use dentations trowel carve to score out waviness on the flat mushy adhesive.

4. Paving mosaic, pay attention to the seam between products themselves remain the same

width slit.

5. Tenderly pat the surface of the mosaic and leveling them to make sure it is adhesive evenly.

6. About 20 hours later when the mosaic is totally adhesive, use special sponge kinife to fill

joint the join fillers in the gap (soft tool to prevent damaging product surface).

7. After 30 minutes, when the joint filler is semi-dry, use wet high density sponge to fill into

joint 1-2mm, which can better show the highlight effect of the product.

8. Use dry towel to clean and finish the installation finally.