- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless Steel

-

Product name:

-

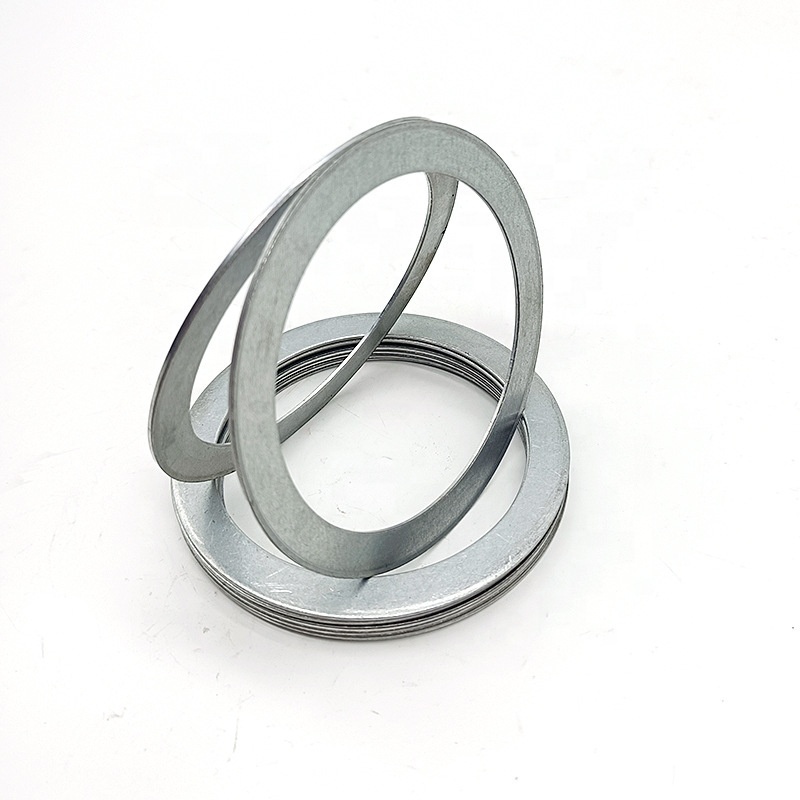

Gasket

-

Application:

-

Industry

-

Color:

-

Customer Request

-

Size:

-

Accept Customize

-

Usage:

-

Sealing Gasket Material

-

MOQ:

-

100pcs

-

Feature:

-

High Temperature Resistance

-

Type:

-

Inner Ring

-

Shape:

-

Custom Shape

Quick Details

-

Place of Origin:

-

Shanxi,China

-

Brand Name:

-

XSY

-

Model Number:

-

XSY-129

-

Material:

-

Stainless Steel

-

Product name:

-

Gasket

-

Application:

-

Industry

-

Color:

-

Customer Request

-

Size:

-

Accept Customize

-

Usage:

-

Sealing Gasket Material

-

MOQ:

-

100pcs

-

Feature:

-

High Temperature Resistance

-

Type:

-

Inner Ring

-

Shape:

-

Custom Shape

Products Show

Processing Information Description

The product is customized products, please consult online customer service

|

Sample name

|

processing precision of non-standard parts

|

|

Machining precision

|

finish machining

|

|

Proofing cycle

|

2 days

|

|

Processing cycle

|

10-15 days

|

|

Product process

|

material preparation - CNC lathe processing - surface treatment - Inspection - packaging

|

|

Processing materials

|

aluminum alloy, stainless steel, brass, etc. (consult customer service for more materials)

|

|

Product features

|

high precision parts, precision up to 0.01

|

|

Product purpose

|

for mechanical equipment parts

|

|

category

|

Features and Applications

|

|

Aluminium alloy

|

Aluminum alloy is light and soft, good strength, good corrosion resistance, good machining performance. Widely used in aircraft,Automobiles, industrial appliances, etc

|

|

Zinc alloy

|

Zinc alloy has low melting point, good fluidity, easy to fuse welding, brazing and plastic processing. Suitable for die casting instrument, steam Car parts shell, etc.

|

|

Magnesium alloy

|

Mainly used to make low load parts. High strength and good corrosion resistance, the shell of electrical products.

|

|

Titanium alloy

|

Titanium alloy has the advantages of light weight, high specific strength and good corrosion resistance, so it is widely used in automobile industry in karma.

|

|

Stainless steel

|

Oxidation resistance, good corrosion resistance, high temperature resistance, widely used in industrial buildings, decoration,some shallow stretching products of the alloy steel.

|

|

Alloy steel

|

According to the addition of different elements, can obtain high strength, high toughness, wear resistance, corrosion resistance,low temperature resistance, high temperature resistance, non-magnetic and other special properties.

|

|

Low carbon steel

|

Good comprehensive performance, strength, plasticity and welding performance is better coordination, used to make steel bars or construction of plant room frame, high voltage transmission tower, bridge, mechanical parts.

|

|

Brass

|

Brass has good mechanical properties, good machin ability, easy brazing and welding, corrosion resistance, but easy to corrosion break Crack. Can be used for large load bearing parts.

|

|

Violet Gold

|

Purple gold has good electrical and thermal conductivity, corrosion resistance and machining performance, can be welded and brazed.

|

|

Sheet metal

|

Sheet metal has light weight, high strength, conductive, low cost, and has been widely used in electronic and electrical appliances, communications, automobile industry, medical instruments and other fields.

|

Custom CNC Machining

We could custom machining parts in different materials of aluminum, stainless steel, titanium and plastic as per drawing or samples.

For new products, if need, we could provide samples for your reference.

Different surface treatment could be made as per your requirements.(anodize, chrome plated, powder coating, laser engraving)

We have professional factory, engineers and international sales.

We will make best quality control from drawing to production, Before packing, we will check all threads and surfaces.

During the whole process, we could keep effective and timely conversation with customers.

We could give you some advice and also modify the products according to your feedback.

We have rich experience of export, so we are familiar with exporting process and documents.

If need, we could apply for certificate of origin for your custom clearance.

For new products, if need, we could provide samples for your reference.

Different surface treatment could be made as per your requirements.(anodize, chrome plated, powder coating, laser engraving)

We have professional factory, engineers and international sales.

We will make best quality control from drawing to production, Before packing, we will check all threads and surfaces.

During the whole process, we could keep effective and timely conversation with customers.

We could give you some advice and also modify the products according to your feedback.

We have rich experience of export, so we are familiar with exporting process and documents.

If need, we could apply for certificate of origin for your custom clearance.

Our Workshop

CNC Machining

CNC Milling

CNC Turning

Our Service

OEM Service

* Customize as per your drawings.

* Customize as per your sample.

* Customize as per your rough idea.

* Customize as per your drawings.

* Customize as per your sample.

* Customize as per your rough idea.

Trade Assurance

* On-time shipment & Order Quality.

* 100% of Assurance Amount Refundable.

* Supplier Performance Feedback.

* On-time shipment & Order Quality.

* 100% of Assurance Amount Refundable.

* Supplier Performance Feedback.

Packing & Delivery

Our Advantages

Customer Feedback

Contact

Hot Searches