One time processing can complete panel 6-side drilling & 2-side grooving works.

Six-sided machining, drilling, grooving, milling, to meet the needs of different productions.

.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Guandiao

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

5400*2750*2200mm

-

Weight (KG):

-

5000 KG

-

Power (kW):

-

15

-

Product name:

-

Side Hole Drilling Machine

-

Control system:

-

PLC

-

Application:

-

Wood Working

-

Keywords:

-

CNC ROUTER

-

Type:

-

other woodworking machine

-

Model:

-

GD-2400

-

Color:

-

black/green/white

-

Item:

-

router cnc woodworking

-

Function:

-

side hole drilling

-

Working Voltage:

-

AC380V/3PH/50Hz(option:220V)

Quick Details

-

Marketing Type:

-

New Product 2024

-

Motor Type:

-

9kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guandiao

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

5400*2750*2200mm

-

Weight (KG):

-

5000 KG

-

Power (kW):

-

15

-

Product name:

-

Side Hole Drilling Machine

-

Control system:

-

PLC

-

Application:

-

Wood Working

-

Keywords:

-

CNC ROUTER

-

Type:

-

other woodworking machine

-

Model:

-

GD-2400

-

Color:

-

black/green/white

-

Item:

-

router cnc woodworking

-

Function:

-

side hole drilling

-

Working Voltage:

-

AC380V/3PH/50Hz(option:220V)

Product Description

1.Complete six sides processing and slotting and milling at one time; Easy to operate, flexible to use, and free from manual intervention.

2.Equipped with a rear feed roller, so the processing plate supports two directions (front and rear) to come out. As for rear

direction, an optional power expenditure roller or a side roller can be selected;

direction, an optional power expenditure roller or a side roller can be selected;

3.Equipped with front, rear, left, right and horizontal hole machining auxiliary pressure rollers; With alll-round auxiliary

pressure processing to ensure the accuracy of horizontal hole machining during workpiece processing.

pressure processing to ensure the accuracy of horizontal hole machining during workpiece processing.

4.Designed with vertical pressure roller to ensure the machining accuracy of vertical hole and slotting.

5.Manufactured with upper and lower spindles, so there is no need to turn the plate for forward and reverse slotting.

6.With automatic dust collector; With extra long X slide rail (5.1 m), which can reduce times of feeding and picking during long workpiece processing, and improve processing efficiency.

7.Allowed to be used for joint processing of hinge holes; The sheet can be mirrored on both sides within a certain thickness range.

New style CNC 6 Side Multi Boring wood cabinets door woodworking six-sided drilling machine.

<Specification>

|

Working size

|

1300x2500mm

|

|

Spindle type

|

3.5KW Air Cooling Spindle*2

|

|

Number of tools

|

12 Vertical top drilling+8 horizontal drilling +9 bottom vertical drilling

|

|

Control system

|

Custom System

|

|

Driver system

|

Absolute servo motor

|

|

Transmission

|

Taiwan helical rack

|

|

X axis Travel speed

|

120m/min

|

|

Y axis Travel speed

|

80m/min

|

|

Re-positioning accuracy

|

±0.03mm

|

|

Software

|

Custom System

|

|

Working voltage

|

220V /380V/ 50-60HZ

|

|

Machine overall size

|

5832*2727*2367mm

|

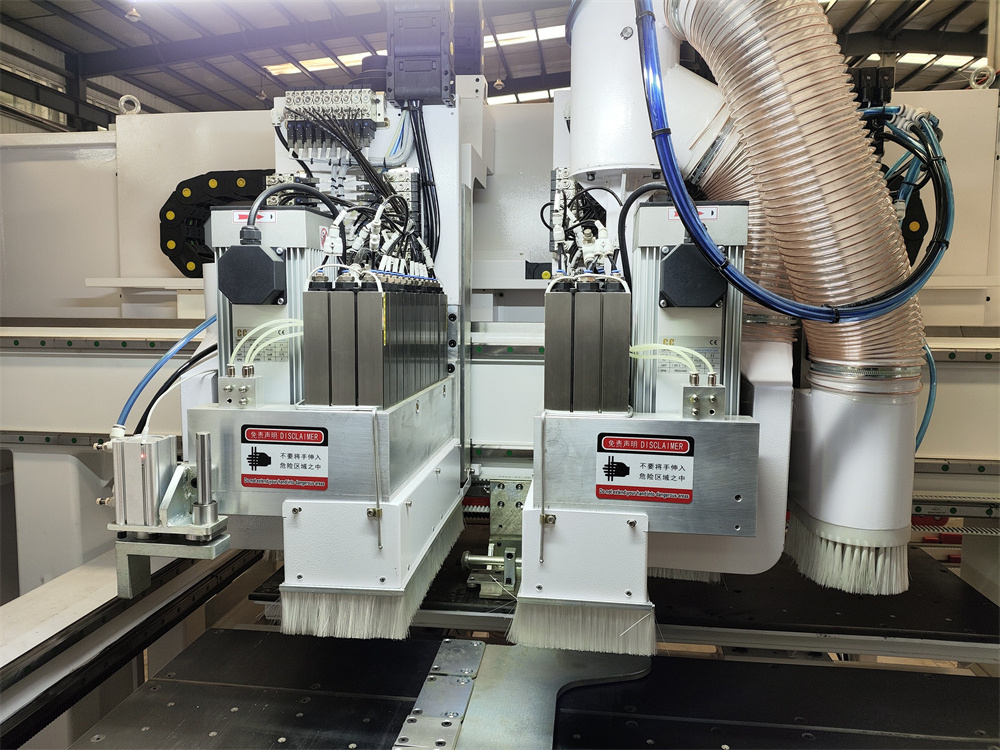

Precision Drilling Heads

.

Using HUAHUA independently developed CNC drilling heads, Manufacturing in accordance with international standards,After

three-coordinate detection, the accuracy is guaranteed.

One time processing can complete panel 6-side drilling & 2-side grooving works.

Drilling bits:

Top: Vertical 9pcs + Horizontal 8pcs

Bottom: Vertical 9pcs

Milling spindle: 3.5kw * 2pcs (1 Top + 1 Bottom) .

three-coordinate detection, the accuracy is guaranteed.

One time processing can complete panel 6-side drilling & 2-side grooving works.

Drilling bits:

Top: Vertical 9pcs + Horizontal 8pcs

Bottom: Vertical 9pcs

Milling spindle: 3.5kw * 2pcs (1 Top + 1 Bottom) .

Double clamps continuously feeding, automatically control the panel feeding and positioning according to the computer drilling

program

Min. process size: 250*50mm;

Max. process size: 2800*1200mm .

program

Min. process size: 250*50mm;

Max. process size: 2800*1200mm .

1.Taiwan Syntec absolute value control, no need for homing, machine can be used immediately once power on.

2. High performance and stability during long service life;

3. Syntec after-sales service branches all over the world. .

Packing & Delivery

Our Service

1.1 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you need replacement.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

If you have any questions about our products, please contact me with no hesitate.

6.Machine has been adjusted before delivery.

If you have any questions about our products, please contact me with no hesitate.

New style CNC 6 Side Multi Boring wood cabinets door woodworking six-sided drilling machine.

Hot Searches