- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LCH

-

Maximum Torque:

-

n/a, 1:1.69

-

Operating Speed:

-

n/a, dia. 6

-

After-sales Service Provided:

-

Overseas service center available

-

Type:

-

Rotary Drilling Rig

-

Power Type:

-

Hydraulic

-

Product name:

-

horizontal directional drilling multi spindle drill head machine

-

Product keywords:

-

multi spindle drill head

Quick Details

-

Place of Origin:

-

Taiwan

-

Weight (KG):

-

6

-

Marketing Type:

-

Hot Product 2021

-

Brand Name:

-

LCH

-

Maximum Torque:

-

n/a, 1:1.69

-

Operating Speed:

-

n/a, dia. 6

-

After-sales Service Provided:

-

Overseas service center available

-

Type:

-

Rotary Drilling Rig

-

Power Type:

-

Hydraulic

-

Product name:

-

horizontal directional drilling multi spindle drill head machine

-

Product keywords:

-

multi spindle drill head

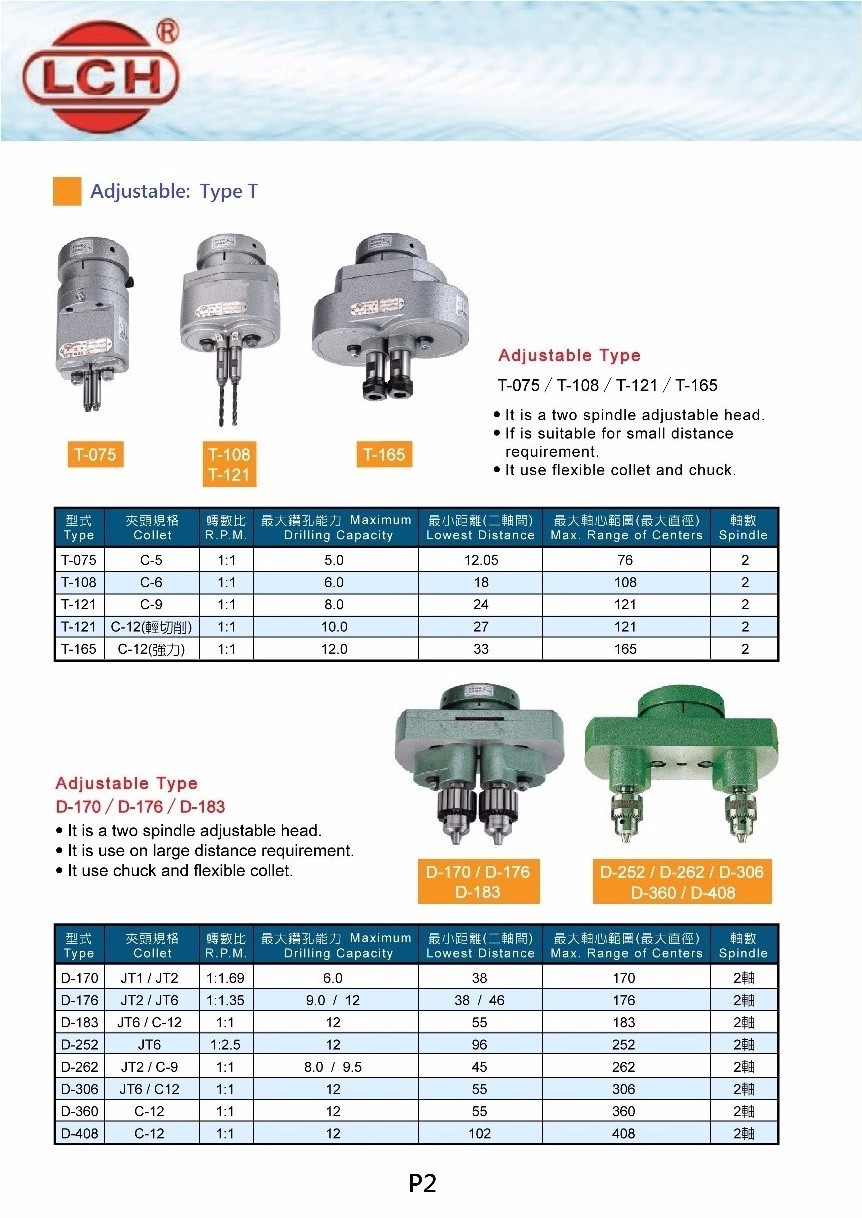

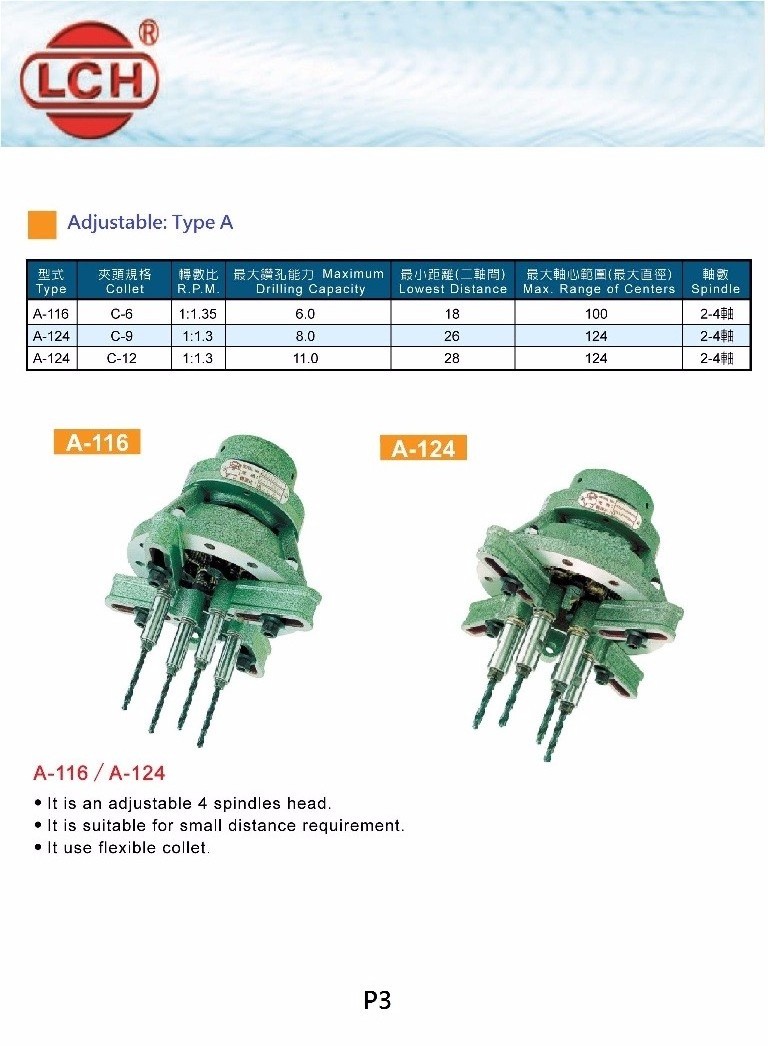

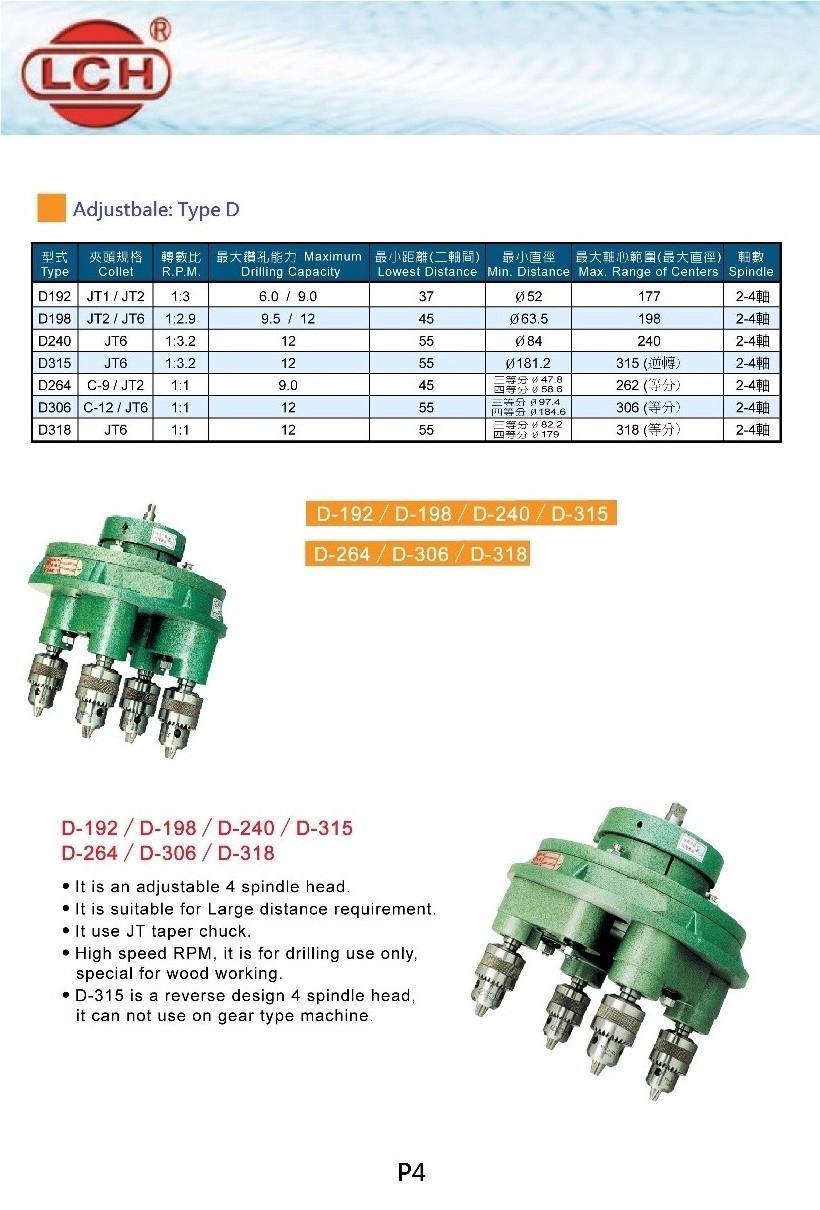

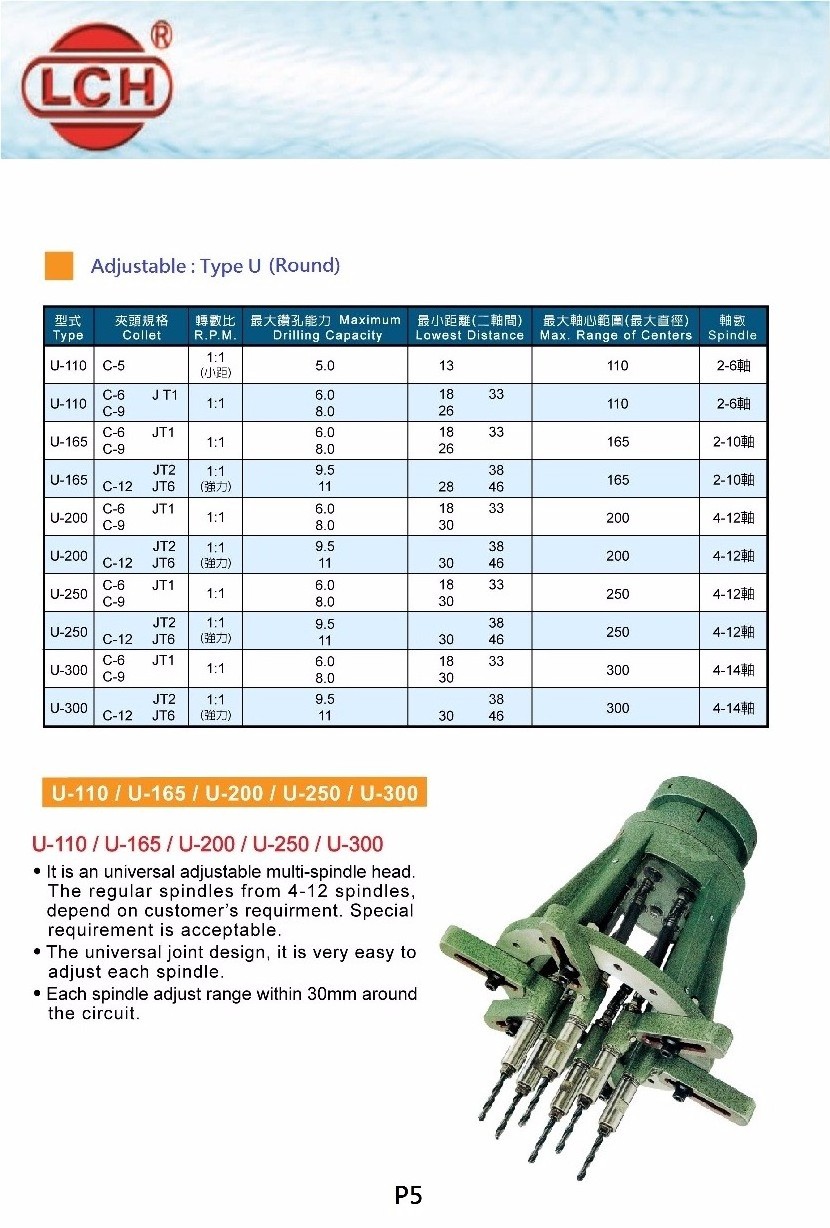

LCH mini horizontal directional drilling multi spindle drill head machine

We are able to offer 2 to 14 adjustable spindle heads choices. It is suitable for large distance requirement and flexible collets and chuck are used. We are able to offer various collet type: JT1 / JT2/JT6/ C-5/ C-9/ C-6/C-12.

Maximum drilling capacity is available from 5.0~12mm. Lowest distance is available from 12.05mm-102mm

Maximum range of centers is available from 75mm~450*600mm

Contact us lch(at)lih-cherng.com.tw for further information .

We are able to offer 8 types of clamping tools

1. C form flexible collet

Advantages: space-saving and can be minutely adjusted between two spindles.

Defect: each flexible collet is used for drill bits or taps uniform in size only for bits or taps in different specs, users need to change the collet

2. JT Drill chuck

Advantages: JT chuck can be used for drill bits and taps in different specs, with no need to be changed

Defect: can be used only when there is maximum space limit between two spindles

3. ER collet

Chuck adjustment range is 1mm; strong clamping force: for universal use.

4. AS adjustable drill spindle

Used for large-bore drilling, this spindle incorporates a mores taper drill, which allows for easy drill spindle length adjustment and easy disassembly of the drill, unlike MT drill spindles which may cause damaging of the drill spindle in the event that the drill is disassembled improperly.

5. FT Floating Drill Spindle (simple floating)

Especially suitable for the tapping of punch-pressed iron plates; provides a 0.5mm floating range to allow for the screw tap to be automatically moved to the hole-processing position by find adjustment.

6. Expansion Tapping Drill spindle (rapid screw tap changing)

It is designed for special-purpose for the tapping of workpieces with different thread pitches: provides wide extension and compensation range. Safety torque device will slip when torque exceeds its limit during processing, preventing the screw tap from breaking so as to damage the workpieces.

7. TR+ER Drill spindle

It is an efficient processing instrument combining the advantages of both the ER collet and the adjustable drill spindle.

8. AS adjustable +MT drill spindle

It is an adjustable + MT drilling spindle is easy to disassemble and adjust the depth of drilling.

With customers from more than 40 different countries shows that the professional technical team, manufacturing team and post-sale team of Lih Cherng Hydraulic (LCH) brings customer's satisfaction.

LCH offers:

1. small order (MOQ 1pc) service

2. after-sales service (through videos, phone call, video conference)

3. Proof of customers satisfaction over 40 different countries who are using LCH hydraulic components

4. Product and system support within 3 hours quickly response service

24-hour helpdesk

with expert support around the clock. Are you tired of limited responses from Chatbots customer support? hydraulic industry is definitely not a business can use Chatbots to offer customer support.

LCH offers helpdesk experts who could be reached via what's app, skype, or wechat app when you are facing any difficulty of hydraulic system. Efficient communication is achieved by having project-specific documentation in place.

5. Batch production & Spare inventory

Batch production way is used in LCH, so inventory quantity is available for customers and part-finished goods are ready to be assembled and shipped anytime.LCH makes sure the inventory quantity available for all period, so customers could always obtain the components in no time.

6. Good packaging

Are you tired of receiving the order damaged du e to poor packaging?

LCH packs each piece with a poly plastic bag in a industrial heavy-duty cartons with proper cushions minimizing damage, strapping on carton and wrapping the carton with film to ensure our customers receiving their orders with peace of minds

7. Quality Control

100% strictly quality control on each multiple spindles drilling or tapping head device (simple random sampling is not acceptable)

Product applications:

The multiple spindles drilling or tapping head device is most widely used machining methods to give precise tolerances with highly standards.

It brings the feature of effectiveness for machining work pieces with complex contours and depths to improve the accuracy and precision of drilling.

Drilling machine is a machine tool which drill holes in a work piece that has been cast or cut. The range could be from plastic application to rough drilling on cast iron or steel material application, such as home appliance like television, air conditioner, washing machine, kitchen applications, or automobil sectors like the parts of car, bicycle, and scooter, as well as parts for electronic products, hardware, and wood applications.

Related multi-spindle machines:

When the multiple spindles work with a multi-spindle machine, it rotates in a horizontal way. One rotation of the drum complete the number of operations which need to be performed for a part to be finished and the drum does this through the division of the required work among the number of spindles in the machine.

Normally multi spindle drill heads are used in mass production since it brings the feature of high efficiency during operation and saving a lot of time where many holes need to be drilled at a time so it increases the productivity. The number of spindles depends on customer's needs.

A multi-spindle machine can have two types of attachments: fixed or adjustable.

In the adjustable drilling head, you can vary the centre distance of the drilling spindle to fit your requirements whereas in the fixed drilling head, centre distance is not allowed to be changed. Related machines are drilling machine, auto tapping machine, double or triple heads drilling and tapping machine, special purpose drilling head machine, vertical machine center, and tapping machines.