- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

180 mm

-

Dimension:

-

customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LangDun

-

Weight (KG):

-

3200

-

Motor Power (kw):

-

7.5 kw

-

Product name:

-

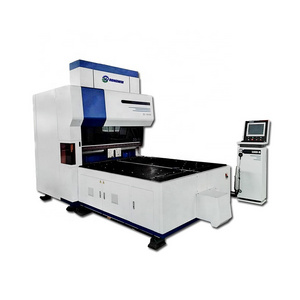

CNC Press Brake Machine

-

After-sales Service Provided:

-

Online Support

-

Raw Material:

-

Sheet

-

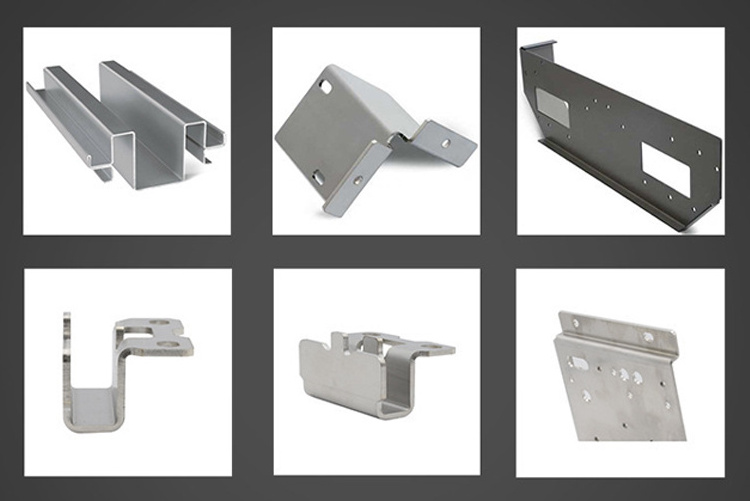

Application:

-

Stainless Plate Bending

-

Type:

-

Hydraulic Bending Tools

-

Keyword:

-

Bending Machine Metal Steel Sheet

-

Usage:

-

Metal Sheet Rolling Bending

-

Function:

-

Metal Press Break

-

Power:

-

7.5kw

-

Color:

-

Customer Choose

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200 mm

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

180 mm

-

Dimension:

-

customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LangDun

-

Weight (KG):

-

3200

-

Motor Power (kw):

-

7.5 kw

-

Product name:

-

CNC Press Brake Machine

-

After-sales Service Provided:

-

Online Support

-

Raw Material:

-

Sheet

-

Application:

-

Stainless Plate Bending

-

Type:

-

Hydraulic Bending Tools

-

Keyword:

-

Bending Machine Metal Steel Sheet

-

Usage:

-

Metal Sheet Rolling Bending

-

Function:

-

Metal Press Break

-

Power:

-

7.5kw

-

Color:

-

Customer Choose

Products Description

CNC Press Brake

The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

1. High bending precision,fast working speed, and efficient,operational safety,performance stably.

2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

3. Using international brand parts and cnc.

4. Visual operating system,easy operation,convenient,multi-functions and practical.

5. All parts are produced by cnc produce center,according to standard drawing.

6. High executive force,high standard and high professional machine assembled team.

7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

9. Providing comprehensive bending program for all press brake,shearing machine user.

10.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

11.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

12.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

13.The similarity of images and shipping machine can reach 99.5%.

14.In time fast delivery.

|

Model

|

WC67Y/K

|

|

|

|

Pressing force

|

1000

|

KN

|

|

|

Working length

|

3200

|

MM

|

|

|

Throat depth

|

320

|

MM

|

|

|

Distance between uprights

|

2600

|

MM

|

|

|

Stroke

|

120/150

|

MM

|

|

|

Table width

|

180

|

MM

|

|

|

Apprach speed

|

100

|

MM/S

|

|

|

Working speed

|

11

|

MM/S

|

|

|

Return speed

|

120

|

MM/S

|

|

|

Motor

|

7.5/11

|

KW

|

|

|

Overall Dimension

|

3200*1600*2600

|

MM

|

|

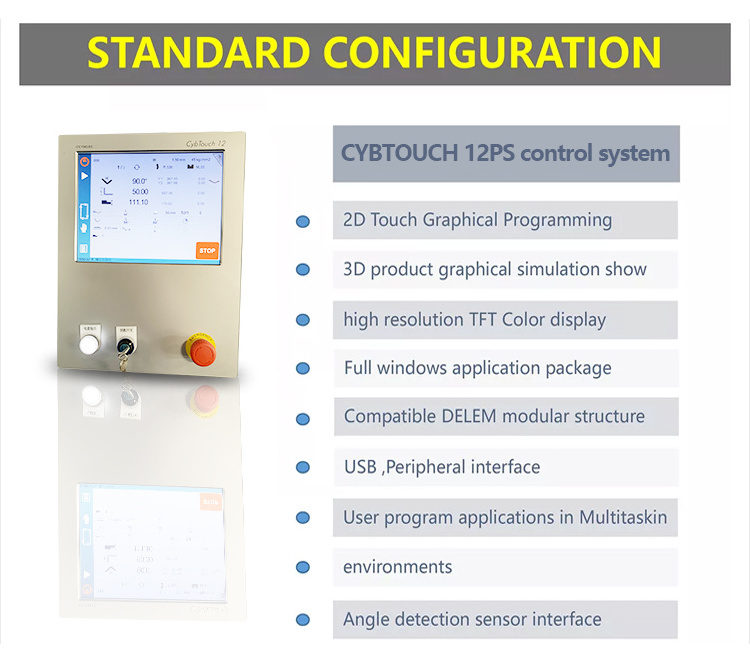

Main Configuration

DA66T CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

Details Images

Hot Searches