Invention Patents authorized in China, US, Canada Australia, Korea, India, Taiwan, Japan and many orher countries and areas.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

50m*12m*7m

-

Year:

-

2022

-

Power (kW):

-

120 kW

-

Weight (KG):

-

10000 KG

-

After-sales Services:

-

Engineers available to service

-

Raw material:

-

All kinds of plastics

-

Throughput Capacity:

-

>=30Mt/Day

-

Oil output rate:

-

40%-70%

-

Certification:

-

CE/TUV/ATEX

-

Reactor life:

-

Over 10 years

-

Noise:

-

<80dB

-

Local Service Location:

-

Germany/India/Thailand/Thailand/Malaysia

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Online/Video technical support

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Niutech

-

Voltage:

-

110V/220V/380V

-

Dimension(L*W*H):

-

50m*12m*7m

-

Year:

-

2022

-

Power (kW):

-

120 kW

-

Weight (KG):

-

10000 KG

-

After-sales Services:

-

Engineers available to service

-

Raw material:

-

All kinds of plastics

-

Throughput Capacity:

-

>=30Mt/Day

-

Oil output rate:

-

40%-70%

-

Certification:

-

CE/TUV/ATEX

-

Reactor life:

-

Over 10 years

-

Noise:

-

<80dB

-

Local Service Location:

-

Germany/India/Thailand/Thailand/Malaysia

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Online/Video technical support

Technical Parameters

|

No.

|

Item

|

Technical Parameter

|

|

1

|

Suitable Raw Material

|

All kiinds of waste tires(rubber)

|

|

2

|

Operation Mode

|

fully continuous operation

|

|

3

|

Structure

|

horizontal type

|

|

4

|

Loading and Discharging

|

fully automatic feeding and discharging

|

|

5

|

Capacity(24h)

|

>=30Mt/Day (customized)

|

|

6

|

Work Pressure

|

normal pressure(slightly negative)

|

|

7

|

Oil Yield

|

43~48%

|

|

8

|

Power

|

50~60kw/h

|

|

9

|

Cooling System

|

cycle water

|

|

10

|

Heating System

|

hot air

|

|

11

|

Noise

|

<=85(dB)

|

|

12

|

Main Reactor Weight

|

40Mt

|

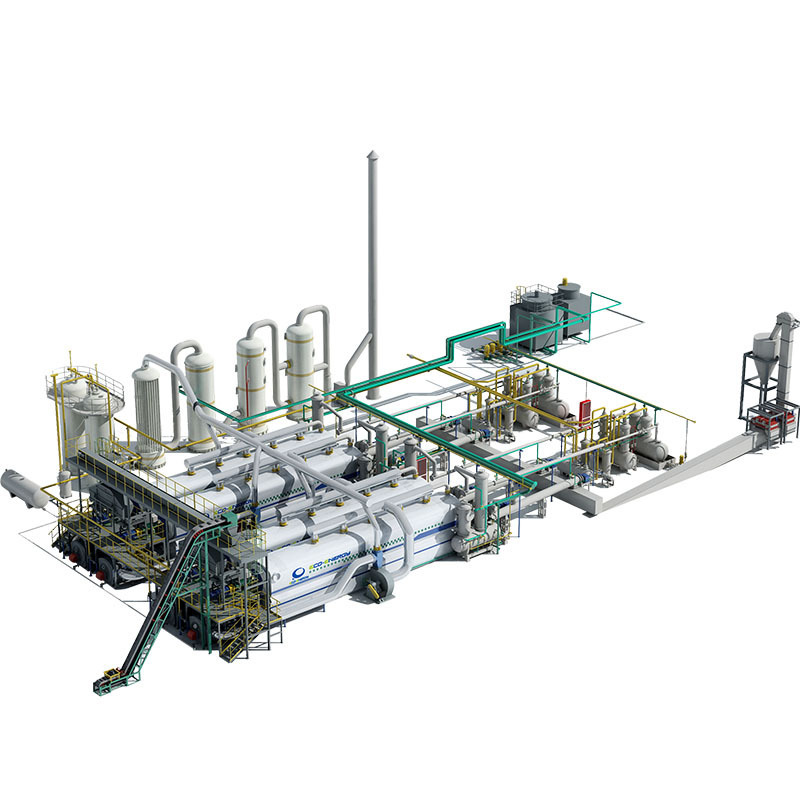

Main Parts of System

Feeding System

Pyrolysis System

In the oxygen-free or oxygen-poor environment, the pyrolysis system function is to complete the pyrolysis reaction of organic waste or hazardous waste and convert the raw material into pyro oil, NCG and solid output under normal pressure, low pyrolysis temperature or catalyst action.

Non-condensable combustible (NCG) gas scrubbing system

While to remove the acid components in NCG, such as hydrogen sulfide, the pressure is also maintained within a reasonable range through the NCG scrubbing system and further supply energy to downstream.

Oil Gas Cooling and Separating System

This system is to cool the gas phase output from pyrolysis reactor to the safe temperature and separate them according to the different boiling points.

Discharging System

The main function of discharging system is to complete the discharge seal, cool and convey the solid output.

Electrical control system

Electrical control system adapts PLC/DCS control system to automatically control the control points. It also has the functions of date collection, calculation, record, printing record, safety alarming etc.

Niutech Pyrolysis Core Technology Advantages

1) The real advanced industrial continuous pyrolysis production mode with large capacity

2) Wide adaptability of raw material

3) Low processing cost

4) P yrolysis rate is better than National Standard that required >99%

5) Excellent enviromental benefit.

6) whole pyrolysis process is completed in the closed pipelines to avoid the dust, VOC leakage issue and the secondary pollution.

7) Emission in compliance with EEA standards in EU and EPA standards in USA

8) Whole line PLC smart control system.H ighly automated. Through the PLC/DCS automatic intelligent control system, it can monitor, collect, display, calculate, process and issue corresponding instructions

9) Few staff required

Oil

Oil Output Rate : 43%- 48%

Solid Feul

Emission comply with EEA standard in EU and EPA standard in USA.

Partial of our patents and awards.

National Invention Patents Certificates.

National Patents Certificates.