- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Local Requirement

-

Power:

-

According to matched equipment

-

Dimension(L*W*H):

-

18*8*7 m

-

Weight:

-

100 kg

-

Features:

-

High Efficiency

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Natural Gypsum Ore

-

Annual capacity:

-

14000tons~300000tons/year

-

Type:

-

Full-automatic

-

Material:

-

Steel

-

Price:

-

Competitive

-

Fuel:

-

Oil Gas Coal

-

Technology:

-

Boiling Furnace

-

Working condition:

-

Stable and safe

-

Experience:

-

Stable and safe

Quick Details

-

Application:

-

Building Material

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dafu

-

Voltage:

-

Local Requirement

-

Power:

-

According to matched equipment

-

Dimension(L*W*H):

-

18*8*7 m

-

Weight:

-

100 kg

-

Features:

-

High Efficiency

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

Natural Gypsum Ore

-

Annual capacity:

-

14000tons~300000tons/year

-

Type:

-

Full-automatic

-

Material:

-

Steel

-

Price:

-

Competitive

-

Fuel:

-

Oil Gas Coal

-

Technology:

-

Boiling Furnace

-

Working condition:

-

Stable and safe

-

Experience:

-

Stable and safe

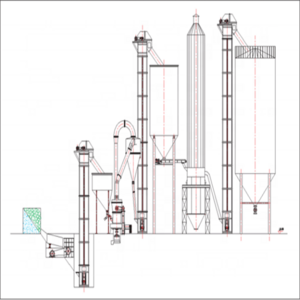

High Efficiency Gypsum Powder Production Line Machine

Gypsum powder production line in construction is a new type production line. And Gypsum powder production line Low investment, short construction period , Gypsum powder production line can be full-automatic . Or we can also control the ingredients artificially . With both the two modes, the production line can produce high-quality products . The former mode needs a larger investment; but its profit is not so obvious in such this small production line. The latter saves the investment, and requires a short production cycle. The plant facilities can be simplified in some way. The user can choose his proposal according to the actual situation. Gypsum Powder , which belongs to green products , has a wide range of uses , and broad prospect for development. Its raw materials are taken from the nature . There’s no pollution and hazardous waste during the production process.