- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

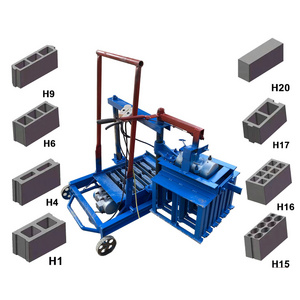

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm

-

Place of Origin:

-

Henan China

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

500 kg

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 5760 pcs/8hours, 3000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm

-

Place of Origin:

-

Henan China

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

500 kg

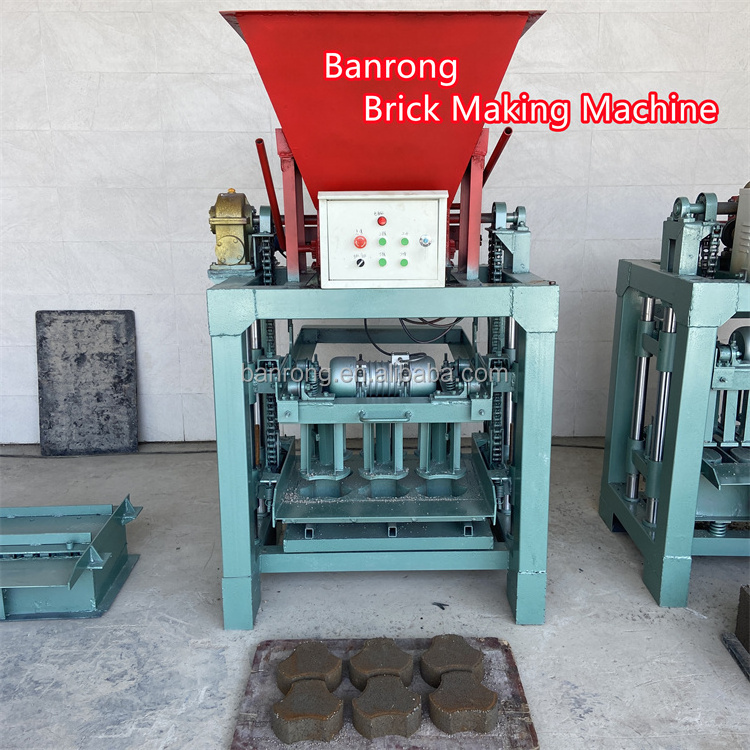

1. It is cheap and durable, easy to operate and uses diesel as power, no need to use electricity. It is quick in product forming, high in product density and strong in pressing power.

2. Distribution system adopts semi-closed mesh rotary forced distribution, which make distribution evenly to guarantee the product strength.

3. Adopting patent technology of double end output four shafts synthesis vibration, which can optimize the vibrator, and make the excited force evenly at vibration table, so that the product weight and strength is evenly and consistent and forming is fast.

4. Multifunctional machine has strong practicability, equipped with different molds which can produce various shapes and models of wall blocks, hollow blocks, pavement bricks, interlocking brick machine, slope-shielding bricks, etc.

Product Uses

1,Usage and features

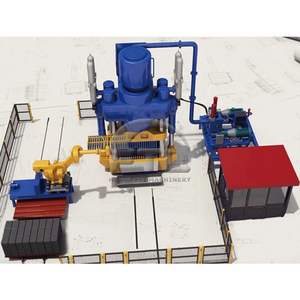

This machine can be constituted a simple production line with JQ350 mixer.

2,Features

The small stationary concrete block making machine adopts both mechanical and electric methods meanwhile to complete its work. It is easy to operate the machine and do the maintainance.

The block machine adopts the way of platform vibration to feed materials. Because of the vertical vibration, the block will be made at a high speed as well as in the form of high density.

3,Machine structure

The concrete block making machine is made up of the machine frame, lifting system, vibration system, mould assembly, electrical control and etc.

4,Machine frame

The frame of the host machine adopts dragon frame structure. It is made of the steel of the right temper so that the host machine is stable, vibration-proofing, and reliable.

5,Lifting system

The lifting system is compose of cycloid pin motor, JZQ250 reducer, lifting arm, hanging pin, positioning pin, and etc.

6,Vibration system

The vibration system of this machine can be divided into two parts. The down platform vibrator adopts two sets of high-speed attached vibration motor with the power of 3kw for each. The up vibrator adopts a high-speed attached vibration motor with the power of 1.5kw. While molding, both the down platform vibrator and the up vibrator vibrate at the same time, making the concrete firm and compressed.

Raw materials of concrete block molding machine brick making

1) low cost and high reliability

2) Durable and cost-effective,electric cabinet control .

3) Solid and Strong Machine Body

4) Perfect after-sale service,spare part and tools free for customer

5) Produce stronger and quality bricks

T he machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below: Nude packing. Bundle packing. Grass rope packing. Water proof packing. Wooden pallets packin g. Wooden box or carton box packing.