- Product Details

- {{item.text}}

Quick Details

-

Thermal conductivity:

-

<=0.14 dry (w/m.k)

-

Raw material:

-

silica sand /cement/lime/aluminium

-

Height:

-

Small(50-250mm)

-

Anti-freeze 15times Freeze and Melt:

-

>=3.2

-

Anti-pressure strength:

-

A3.5

-

Dry Shrink Coefficient:

-

<=0.5

-

Type:

-

Wallboard

-

Application:

-

Interior Walls, Exterior walls, roofings &floors

Quick Details

-

Place of Origin:

-

Shandong, China

-

Color:

-

White

-

Dry density grade:

-

<=525kgs/cbm

-

Thermal conductivity:

-

<=0.14 dry (w/m.k)

-

Raw material:

-

silica sand /cement/lime/aluminium

-

Height:

-

Small(50-250mm)

-

Anti-freeze 15times Freeze and Melt:

-

>=3.2

-

Anti-pressure strength:

-

A3.5

-

Dry Shrink Coefficient:

-

<=0.5

-

Type:

-

Wallboard

-

Application:

-

Interior Walls, Exterior walls, roofings &floors

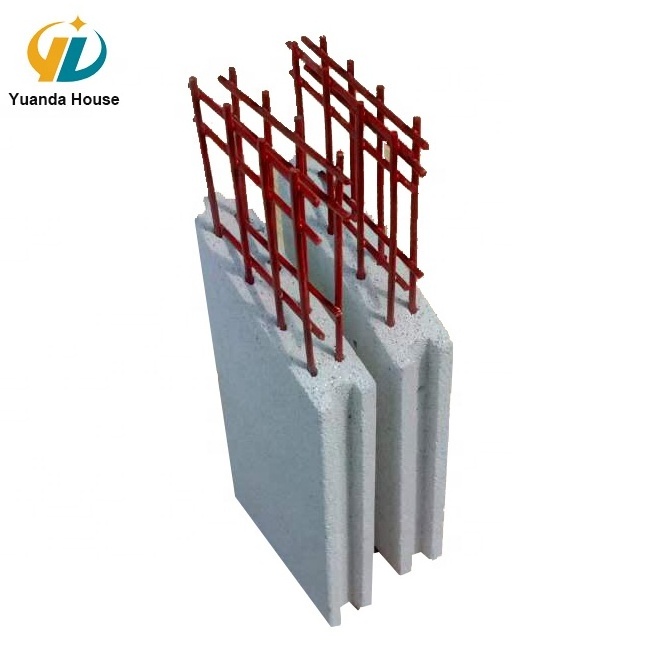

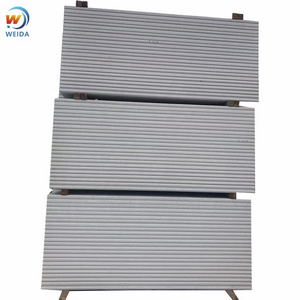

B05 AAC/ALC Autoclaved Lightweight Wall Panels Cladding Materials

INTRODUCTION

AAC (shorted for autoclaved aerated concrete) panels are mainly made of silica sand, cement, aluminium, lime, gypsum, processing in the condition of high temperature, high pressure and steam curing. They could be used in industry buildings and residential buildings. Now, they are welcomed by more and more customers.

SPECIFICATIONS

Technical Information:

| Item | Model | ||

| B05 | B06 | ||

| Anti-pressure Strength | A3.5 | A5.0 | |

| Dry Density Grade(kg/m3) | <=525 | <=625 | |

| Thermal conductivity[W/(m.k)] | <=0.14 | <=0.16 | |

| Anti-freeze 15 times Freeze &Melt | Quality loss(%) | <=5 | |

| Strength after freezing(Mpa) | >=3.2 | ||

| Dry Shrink Coefficient | <=0.5 | ||

Specifications of AAC panels for walls:

|

Thickness(mm) |

50 |

75 |

100 |

120 |

150 |

175 |

200 |

|

Maximal Length (mm) |

2000 |

3000 |

4000 |

4500 |

6000 |

6000 |

6000 |

Specifications of AAC panels for roofing:

|

Thickness/mm |

75 |

100 |

125 |

150 |

175 |

200 |

|

Intensity of Pressure(N/m2) |

Maximal Length (mm) |

|||||

|

800 |

2000 |

3000 |

3500 |

4200 |

4800 |

5200 |

|

1000 |

2000 |

3000 |

3500 |

4200 |

4800 |

5200 |

|

1200 |

1960 |

2920 |

3400 |

4080 |

4640 |

5200 |

|

1400 |

1920 |

2840 |

3300 |

3960 |

4480 |

5200 |

|

1600 |

1880 |

2760 |

3200 |

3840 |

4320 |

4950 |

|

1800 |

1840 |

2680 |

3100 |

3720 |

4160 |

4900 |

|

2000 |

1800 |

2600 |

3000 |

3600 |

4000 |

4800 |

|

2200 |

------ |

2500 |

2850 |

3350 |

3750 |

4700 |

Specifications of AAC panels for floors:

| Length(mm) | 100 | 125 | 150 | 175 | 200 |

| Intensity of Pressure(N/m2) | Maximal Length (mm) | ||||

| 2400 | 2400 | 2700 | 3100 | 3500 | 4000 |

| 2600 | 2330 | 2630 | 3030 | 3430 | 3950 |

| 2800 | 2260 | 2560 | 2960 | 3360 | 3900 |

| 3000 | 2200 | 2500 | 2900 | 3300 | 3850 |

| 3200 | 2130 | 2460 | 2830 | 3230 | 3780 |

| 3400 | 2060 | 2430 | 2760 | 3160 | 3730 |

| 3600 | 2000 | 2400 | 2700 | 3100 | 3670 |

| 3800 | 1950 | 2350 | 2650 | 3050 | 3620 |

| 4000 | 1900 | 2300 | 2600 | 3000 | 3530 |

| 4200 | 1840 | 2240 | 2560 | 2960 | 3480 |

| 4400 | 1780 | 2180 | 2520 | 2920 | 3430 |

| 4600 | 1720 | 2120 | 2480 | 2880 | 3400 |

| 4800 | 1660 | 2060 | 2440 | 2840 | 3360 |

| 5000 | 1600 | 2000 | 2400 | 2800 | 3340 |

| Item | Model | Test result (db) | Standard of test | Application |

| 1 | 100mm AAC panel | 36.7 | GBJ75-84 GBJ121-88 | interior walls of housing units/general division walls of schools/hotels/office buildings |

| 100mm AAC panel+2 sides of putty (3mm) | 40.8 | |||

| 2 | 120mm AAC panel | 41.7 | interior walls of housing units/general division walls of schools/hotels/office buildings(5A Grade) | |

| 120mm AAC panel+2 sides of putty (3mm) | 45.1 | |||

| 3 | 150mm AAC panel | 43.8 | interior walls of housing units/schools/hotels/office buildings | |

| 150mm AAC panel+2 sides of putty (3mm) | 45.6 | |||

| 4 | 180mm AAC panel | 46.7 | division walls of rooms that require silence | |

| 180mm AAC panel+2 sides of putty (3mm) | 48.1 | |||

| 5 | 200mm AAC panel | 49.8 | division walls of rooms that require silence, eg., a cinema, a 5-star hotel | |

| 200mm AAC panel+2 sides of putty (3mm) | 51.3 | |||

| 6 | (75+5space+75)mm AAC panels | 48.6 | division walls of rooms that require silence in some industry, eg., division walls of a high-standard Hotel | |

| (75+5mineral wool+75)mm AAC panels | 54.8 | |||

| (75+5mineral wool+75)mm AAC panels+2 sides of putty (3mm) | 57.6 |

|

Item |

Features |

Details |

|

1 |

Lightweight |

Autoclaved Aerated Concrete panels/blocks are one-fifth of the weight of concrete and are produced in easily handled sizes. ( Dry density grade is 525KG/m3 ) |

|

2 |

Economy |

Using AAC panels can shorten the construction period in half because of its lightweight and easy workability. In most cases the need for supplementary insulation can be avoided. |

|

3 |

Energy-saving (Thermal conductivity is 0.11 ) |

Thermal conductivity of Autoclaved Aerated Concrete panels is one-tenth of that of concrete, that means insulated features are 10 times than concrete. Thermal insulation for AAC panels of thickness 100mm is equal to clay tile wall of 300mm. Therefore, AAC panels are building materials with excellent features of thermal insulation. |

|

4 |

Sound insulation |

Sound insulation for Autoclaved Aerated Concrete panels of 100mm is 40.8db, while 150mm is 45.6db. There are a lot of separate crystal-shaped blowholes in the panel, so the panel has the features of sound insulation and acoustic absorption. |

|

5 |

Fireproofing ( 4 hours ) |

The fire-resistant time for AAC panels of 100mm is 3.42hours while 120mm is 4 hours. The original materials of AAC panels is totally inorganic and is incombustible, and will not volatilize noxious gas even under the high temperature. The product is especially suited for fire-rated applications . |

|

6 |

Load bearing |

The intensity of pressure for cube is more than 4mpa. The load bearing capacity for one point is more than 1200N. The rebars within AAC panels are made according to computer calculating force. As a non-loadbearing cladding , AAC panels can be used under circumstances of pressure. |

|

7 |

Anti-vibration |

As a building envelope , AAC panels are known for their excellent anti-vibration by architects. In a simulated earthquake experiment (seismic intensity 10.5), none of the panels fracture, and joints of test construction are undamaged. |

|

8 |

Environmental protection |

The Autoclaved Aerated Concrete is designed for consumers who are environmentally conscious. It helps reduce at least 30% of environmental waste, decrease over 50% of greenhouse radiation and over 60% integrated energy on the surface of brick. |

|

9 |

Durability |

AAC panels are buiding materials of inorganic silicate and not affected by harsh climatic conditions and will not degrade under normal atmospheric conditions. The service life matches with all kinds of construction. |

|

10 |

Efficiency |

The Autoclaved Aerated Concrete product’s lightweight and easy workability means it is very quick to install on site, and the construction period will be shortened in half. |