- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAMEL MACHINERY

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

10mx2.5mx3m

-

Power (kW):

-

58

-

Weight:

-

5000 KG

-

Name:

-

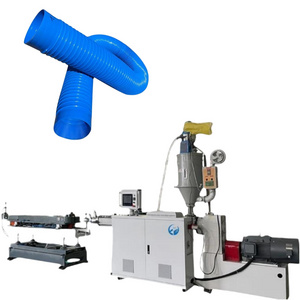

PE PP PVC PA polymer flexible corrugated pipe making machine

-

Color:

-

Customised

-

Motor brand:

-

Siemens Beide/WNM

-

Inverter:

-

ABB/HOLIP

-

Contactor:

-

DELIXI/Siemens

-

Temperature controller:

-

Omron/RKC

-

Gearbox:

-

Guomao Brand

-

Screw material:

-

38CrMoAlA Nitrogen

-

Pipe Material:

-

PE HDPE PP PVC PA ABS

-

Line speed:

-

10-28m/min

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAMEL MACHINERY

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

10mx2.5mx3m

-

Power (kW):

-

58

-

Weight:

-

5000 KG

-

Name:

-

PE PP PVC PA polymer flexible corrugated pipe making machine

-

Color:

-

Customised

-

Motor brand:

-

Siemens Beide/WNM

-

Inverter:

-

ABB/HOLIP

-

Contactor:

-

DELIXI/Siemens

-

Temperature controller:

-

Omron/RKC

-

Gearbox:

-

Guomao Brand

-

Screw material:

-

38CrMoAlA Nitrogen

-

Pipe Material:

-

PE HDPE PP PVC PA ABS

-

Line speed:

-

10-28m/min

Products Description

Plastic Single wall corrugated pipe production line

This extrusion line consists of extruders, die head, corrugation forming machine with modules, coiler etc. and can produce different sizes of corrugated pipes.

Features:

1.Extruder: high efficient screw, hard gear surface gearbox, uniformed raw material heating, good plasticization, high extrusion speed.

2.Corrugation forming machine: closed structure, module link in the overall closure base does round-trip running in the running tunnels.

3.Forming modules: it is made of hard steel, dealed with a rigorous use of CNC finishing materials produced to ensure the hardness and precision of the molding modules. These modules are easy and convenient to change

4.Coiler :Single position or double position with torque motor.

5.Electrical parts: ABB inverter, Schneider contactor, RKC thermo controllers etc.

1.Extruder: high efficient screw, hard gear surface gearbox, uniformed raw material heating, good plasticization, high extrusion speed.

2.Corrugation forming machine: closed structure, module link in the overall closure base does round-trip running in the running tunnels.

3.Forming modules: it is made of hard steel, dealed with a rigorous use of CNC finishing materials produced to ensure the hardness and precision of the molding modules. These modules are easy and convenient to change

4.Coiler :Single position or double position with torque motor.

5.Electrical parts: ABB inverter, Schneider contactor, RKC thermo controllers etc.

Main technical parameter:

1. (Normal speed)

|

Model

|

Pipe Diameter

(mm)

|

Extruder

Model

|

Output

(kg/h)

|

Total Power

(kw)

|

Module No.

(pairs) |

Production Line Speed

(m/min)

|

|

CMDB -12

|

ᴓ6-12

|

SJ-45

|

40-60

|

16

|

42

|

6-12

|

|

CMDB -32

|

ᴓ16-32

|

SJ-50

|

50-70

|

23

|

48

|

6-12

|

|

CMDB -63

|

ᴓ20-63

|

SJ-65

|

60-100

|

38

|

56

|

4-8

|

|

CMDB -80

|

ᴓ50-80

|

SJ-75

|

70-130

|

64

|

72

|

3-8

|

2. (High speed)

|

Model

|

Pipe Diameter

(mm)

|

Extruder

Model

|

Output

(kg/h)

|

Total Power

(kw)

|

Module No.

(pairs) |

Production Line Speed

(m/min)

|

|

CMGB -14

|

ᴓ7-14

|

SJ-45/SJ50

|

40-80

|

25

|

70

|

10-20

|

|

CMGB -58

|

ᴓ16-58

|

SJ-65/SJ75

|

60-120

|

46

|

74

|

10-25

|

PE PP PVC PA EVA single wall corrugated conudit pipe extrusion line

Single wall corrugated pipe extrusion line designed by our company can produce PP/PE/EVA/PVC etc single wall corrugated pipes, which takes the advantages of high temperature resistance, abrasion resistance, corrosion resistance, high strength. This hose can be widely used in wire and cable products threading pipes, washing machine drains, vacuum cleaner, ventilation pipes, tubes, etc.

Hot Searches