- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

4200*1000*2600~9200*2600*5000

-

Weight (KG):

-

2000 KG

-

Product name:

-

micro fine Grinding Mill Pulverizer

-

cooling method:

-

water cooling

-

Material:

-

Stainless steel

-

Capacity:

-

60~1300kg/h

-

Keyword:

-

fine Grinder,fine Pulverizer,Grinding machine

-

Speed of principal axis(rpm):

-

2800~6000

-

Crushing Fineness(mm):

-

80-500(Adjustable)

-

Weight:

-

980~4200kg

-

Power:

-

13.5~122kw

Quick Details

-

Output (kg/h):

-

10 - 120 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HuiXu

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

4200*1000*2600~9200*2600*5000

-

Weight (KG):

-

2000 KG

-

Product name:

-

micro fine Grinding Mill Pulverizer

-

cooling method:

-

water cooling

-

Material:

-

Stainless steel

-

Capacity:

-

60~1300kg/h

-

Keyword:

-

fine Grinder,fine Pulverizer,Grinding machine

-

Speed of principal axis(rpm):

-

2800~6000

-

Crushing Fineness(mm):

-

80-500(Adjustable)

-

Weight:

-

980~4200kg

-

Power:

-

13.5~122kw

Standard Models of HX-WFJ series fine Grinding machine:

Standard Models of HX-WFJ series fine Grinding machine:

|

product Name |

Micron fine powder grinder grinding machine Impact grinder |

|||||

|

Model |

WFJ-15 |

WFJ-20 |

WFJ-30 |

WFJ-60 |

WFJ-80 |

WFJ-100 |

|

Capacity(kg/h) |

60-150 |

150-300 |

150-400 |

200-500 |

300-1000 |

800-1300 |

|

Size of input granules(mm) |

≤10 |

≤12 |

≤15 |

≤20 |

≤20 |

≤20 |

|

Crushing Fineness(mm) |

80-500(Adjustable ) |

|||||

|

Motor power(kw) |

13.5 |

22 |

46 |

84.15 |

102 |

122 |

|

Speed of principal axis(rpm) |

≈6000 |

≈4800 |

≈3800 |

≈2800 |

≈2800 |

≈2800 |

|

Overall Size(L*W*H) |

4200*1000*2600 |

4700*1200*2700 |

6640*1300*3960 |

7500*2300*4530 |

8200*2500*4600 |

9200*2600*5000 |

|

Weight(kg) |

980 |

1300 |

1500 |

4200 |

4200 |

4200 |

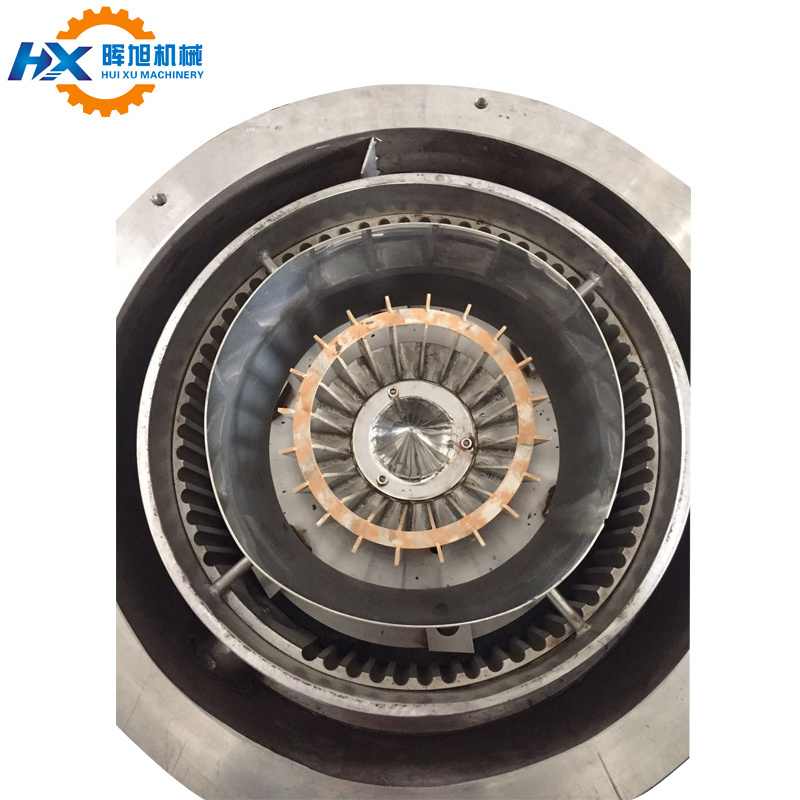

Working Method:

The material enters the grinding chamber via the funnel and spiral conveyor it is sheared and broken by the fast-rotating blades. The powder passes the guide ring and enters the classification chamber. AS the classification wheel is in revolution, both the air force and centrifugal force act on the powder . As the particles whose diameters are greater than the critical diameter(diameter of the classification particles) have a great mass, the yare thrown back into the grinding chamber to be ground again,while the particles whose diameters are smaller than the critical diameter enter the cyclone separator and bag-type collector via the material exit pipe by means of negative pressure wind conveyance. The discharge material meets the requirement for the product.

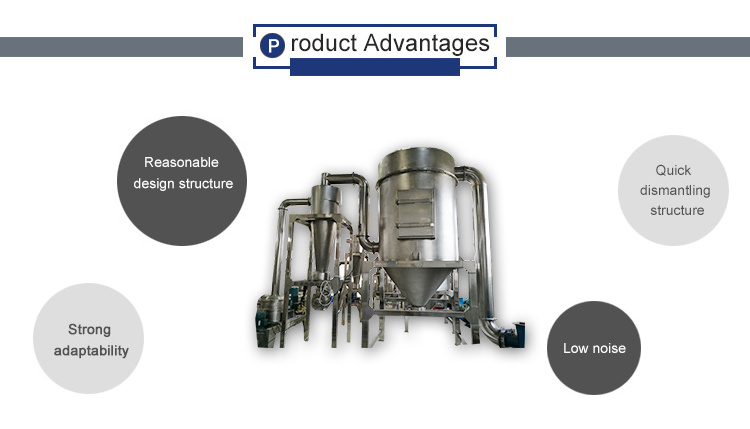

Main Merits And Features:

1. The design is compact and structure reasonable. The machine is equipped with an internal classification mechanism so that grinding and classification are carried out simultaneously, thus reducing energy consumption.

2. Euipped with a draught fan, which dissipates the heat in the machine continuously, the machine is fit for the grinding of thermal sensitive materials.

3. Having a great adaptability and narrow granularity distribution. The granularity of the product is even and fineness may reach 80-320 mesh.

4. Regulate the speed of the classifier or amount the air without stopping the machine and evenly distributed products of the required granularity will be obtained.

5. The top cover of the main machine is opened with pneumatic springs and the body is contructed in such a way that it may be opened to two sides so that no hindrance will be met in cleaning and servicing the internal parts.

6. The main grinding parts are made of high-grade alloy tool steel so that the service life or change cycle of the wear parts is greatly lengthened.

7. High-speed precision bearings imported from abroad are adopted for the bearing system so that the whole machine runs smoothly with little vibration and noise.

8. The pipes are of quick – detachment construction, making detachment and cleaning quick and convenient.

9. Equipped with a cyclone separator and a collector , so there is no powder flying during production. The dust collecting bag can effectively collect the fine powder in the air current so as to meet the requirements for cleanness and environmental protection in waste gas discharge.

10. The fine powder collected by the dust collecting bag can be effectively recycled. Thus the material loss is reduced.

Jiangyin Huixu Powder Machinery Manufa cturing Co.,Ltd is Located in the Zhutang Town of Jiangyin city,Jiangsu province . The company has a professional technical team a nd strong technical force . Our company's product ions mainly include six major categories sush as p ulverizer , mixer , dryer , sifter , granulator and so on. Product ion s are widely used in food, spice, chemical industry . Our company always take the "quality first" as the purpose .

Warmly welcome foreign friends to our company for visiting and guidance .

A. Technical service

1, We calculate the capacity and recommend the best models.

2, We supply you the professional refrigeration technical support and electronic technical support for your installation, debugging and operation.

3, We supply the spare parts and technical support in & after the warranty time.

4, We supply the training course to your workers at our factory if you need.

B. After-sales service

1, Technical support for your installation, operation and maintenance.

2, One year’s warranty, and you can pay for extended warranty.

3, Spare parts and technical support at most economic prices after the warranty.