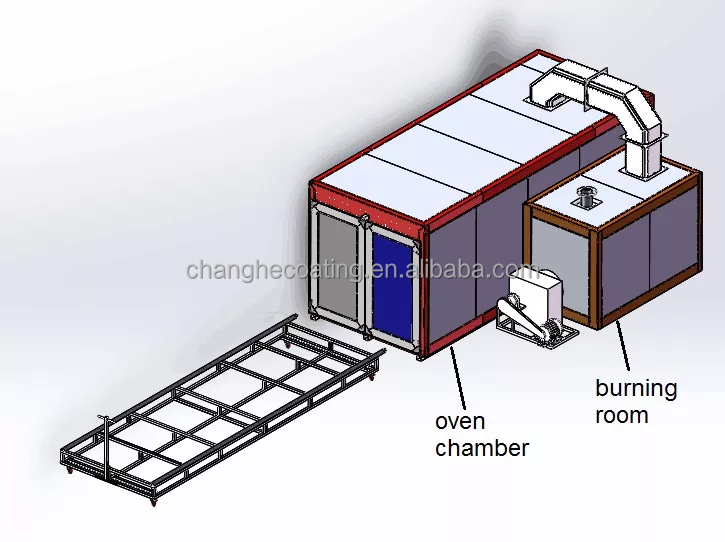

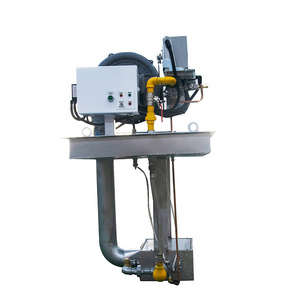

-Imported burner, takes full utilization of fuels,making chamber rapidly and raise to required, temperature.

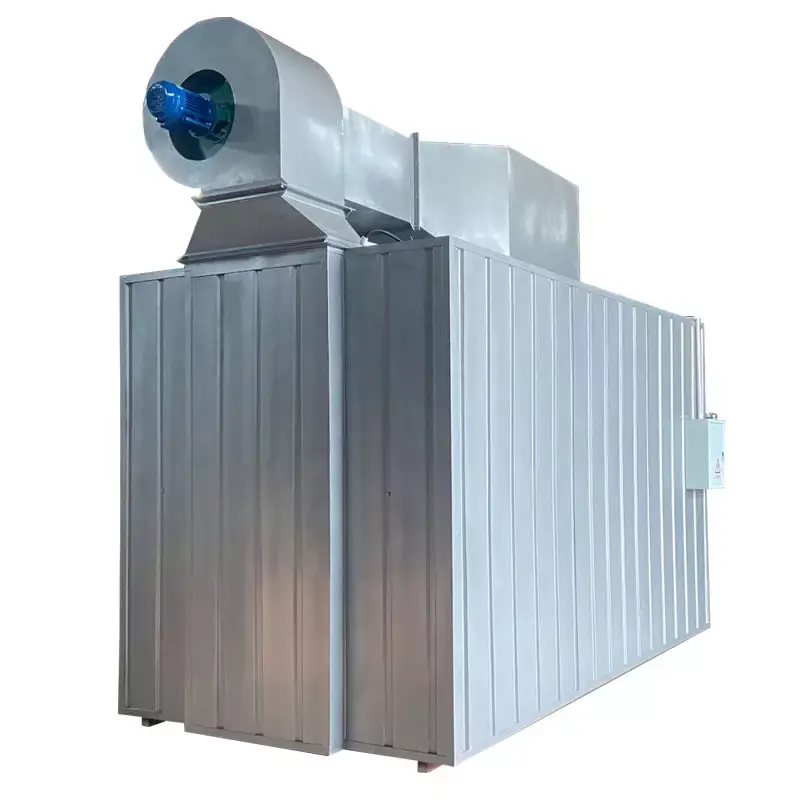

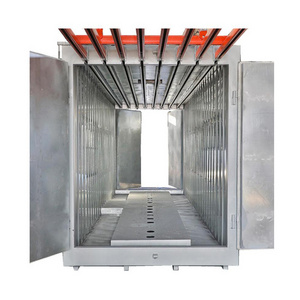

-The heating chamber is directly transferred to the inside of the oven through the circulating fan, and the circulating fan continuously circulates to make the internal temperature of the oven Continue to rise to the set temperature, the distribution is even and consistent.